Professional Documents

Culture Documents

JOB Procedure - Compressed - Compressed

Uploaded by

Vineet Agrawal0 ratings0% found this document useful (0 votes)

73 views48 pagesOriginal Title

JOB Procedure_compressed_compressed

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

73 views48 pagesJOB Procedure - Compressed - Compressed

Uploaded by

Vineet AgrawalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 48

a ashe

| 6a Sats BOON SORRTECH

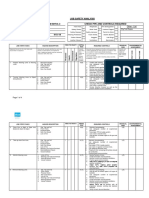

INSPECTION REPORT : FOR CALIBRATION OF INSTRUMENTS

Pao Ree Tenis

jauen hfs MRORYAN PTROLEUNNESMMORAVOR AEA) fia im

CONSUCTANT Js exces woWATo.-reu esr Ne f

CONTRACTOR | conmrecunemATIONA RATS (eRj oat

‘icin

nnSTRUWENTS DEALS caiman peta

NsTRUWENTES f fra

nRUMENTS r TnSTRUMPNTS DEAS

ar oremmmavon raion

Tnamiment Aa ag

jstetneamert Inet Reg

wo] ie t Randing while Coming downthe Difference Ditterence br % Remerks

cert wningoevntoetie

ve

Cy

t

{

} -

|

REVARRS

For tis EILUMPCL

wen sow

ome ore

PROJECT PALANPUR VADODARA PIPE LINE PROJECT PART A. (PVPL)

CUENT M/s: - HINDL'STAN PFTROLFUM CORPORATION LIMITED.

~(HPCL)

CONSULTANT | M/s - ENGINEERS NDIA LTD. - (EIL]

JOB NO.: A848

“CONTRACTOR | | M/s - CORRTECK INTERNATIONAL PVT.LTD.-(CIP) _

LOI NO.: 17000045-0Q-101L29 DATED : 04.08.2017 |

JOB PROCEDURE FOR

PIPELINE MARKER INSTALLATION

| PROCEDURE No.: HPCL/EIL/CIPL/PVPL/ML/ JP-26

ce

PROJECT PALANPUR VADODARA PIPE LINE PROJECT PART A

CUENT __M/s | HINDUSTAN PETROLEUM CORPORATION LIMITED - (PCL)

CONSULTANT | M/s i- ENGINEERS INDIA LTD - (EIL) _

| CONTRACTOR [M/s = CORRTECH INTERNATIONAL PVT.LTD. - (CIPL)

| LOLNO : 17000045-0Q-10129 DATED : 04.08.2017 |

__ JOB NO : A848 _

JOB PROCEDURE FOR

PIPELINE MARKER INSTALLATION

|

DOCUMENT NO: HPCL/EIL/CIPL/PVPL/ML/JP-26 | |

~_ Review and Approval

Nane

{ |

on | oesaaor | eae

eee Mie CIPL

[TO PROCEDURE E08 PIPELINE _ DOCUMENT NO

MARKERINSTALLATION —_/ HIPCL/EHL/CILPUPLIMLI:P-2

= Ar NINERS ey

| cliche NUN ©

a Sabb SNE ORR TECH

PROJECT | PALANFUR VADODARA PIPE LINE ®ROJECT PART-A qj

CUENT M/s: - HINDUSTAN PETROLEUM C RATION LIMITED

CONSULTANT M/s :- ENGINEERS (NDIA LTD - (ELI

TCONTRACTOR | M/s: CORRTECH INTFANATIONAL PVT.LTO - (CIPL)

Contents

Sr.No Description

mn Page No.

1 Purpose T 3

2 Scope of Wark a 407

“3 Reference 3

+ ___

@ Responsibility

— a oo

S| Methodolopy 5-7

6 Safely & Environment | 7

7 = ity Aessurance / Quality Control 7

aa |

8 Bocumentation 7

Inspection Test Plan ITP 1915,

Inspection Report Li —

OB PROCEDURE FOE PIPELINE DOCUMENT NO,

PARKER INSTALLATION HPCL/EIL/ CIPL/PVPL/MI/IP 26 00

Rat evans

eee —

=) |

a

PROJECT “TPALANPUR VADODARA PIPE LINE PROIECT -PART-A

CLIENT Mis :- HINDUSTAN PETROLEUM CORPORATION LIMITED —(HPCL)

CONSULTANT — M/s: ENGINEERS INDIA LTD - {ETL}

CONTRACTOR M/s :- CORATECH INTERNATIONAL PVT.LTD. - (CIPL)

4. PURPOSE

The pi

ante’ the

"DIA

CORRTECH INTERNATICNAL PVT. LTD

20 SCOPE

cline markers for the

PART & Construction

The scope cavers the supaly, fabrication and installation

canetruction of 18” DIA PALANPLIE VADODARA PE LINE

Work, by M/s. - CORRTECH INTERNAT:ONAL PVT. LTD.

3.0 REFERENCE

Following documents in total ty or in part shal form the reference oorumens

«Speci

0057 Rev de

quid Hycrocarhons ane Other Licuas ASME

tion for Fipgline Markers €

+ Pipeline Transportation Systems to

Rat ads

et Editon

+ APL-RP.1102 Recommended Practice for Marking Ligui! Petroleum p1peline facil

«© Standard Spec'fication for Shop anc Field psinting -6-44-0004

* EL STD 7-71-9008 KM F

STD. 7-74-0002 Tyo

al ROW Boundary Marker

STD 7-71-0010 Aeria, Marker

STD 7-71-0011 Direction Marker

SDT

«© BLSID. 7-71

“0042 Pipeline Warning Sign

4 Navigab'e Wetenway Fipeline Crossing w:

PROIECT PALANPUR VADODARA PIPE (INE PROJECT -PARTA

CLIENT “nafs. - HINDUSTAN PETROLEUM CORPORATION LIMITED -(HPCL)

CONSULTANT | M/s. ENGINEERS INDIA LTD (IL)

CONTRACTOR M/s - CORATECH INTERNATIONAL PVT.LTD. - (CIPL}

40 RESPONSIBILITY

Project Manager

ent Construction Manager

QAIQC Spead in-charge :

GAIGE Engine:

Store in-charge

108 PROCEDURE FOR PIPELINE. |

MARKER INSTALLATION

Shall revert to Project GAY

Hea e W/ciPL/PVPL NGL TE

Shell repo to Project Director

ll provide all recessery resources to implemen:

tvs procedure:

Shall report to the Project Manager.

Shall be vespunsible for overall implementation

monitenng of construction and

commissio

Manager (Technically) &

tively

for the compliance of this

Project manager (adminis:

Shal be respon

ure

Shal be resporsible for overall contro! of QC activities

and sub- contractors QC ect vties. implernentation cf

QAM ard supervision and allocation of inspecton

teams, develop inspection and test plens

pr

Shall report to QAVOC Spread n-charge,

Shall ensure proper imple tior of this procedure,

Shall checks and ve the pipeline marker

fabrication & installation act ities

Verifies and countersigns pipeline marker fabneation &

installation report

Shall report to the Resicent Gonstauction Manege

Preparation of raceip: coos addrnssing specific is

and charactenstics of each spreac

Responsible for overal

and for the implement

supervises Ihe activity. Generates reports dunng the

activity ana recorss data

control and sefety managerient

‘on of work inst-uction ane

Explains to tally foreman and ail ather persons involves

in stores of the etal

vane

Saag

— Saaae A ANGNIR.

ae Seaitat SNH Mle MID SORRTECH

| pRoWECT PALANPUR VABODARA PIPE LINE PROJFCT PART-A

“curwr [M/s HINDUSTAN PETROLEUM CORPORATION LIMITED - (HCL)

CONSULTANT — M/s: ENGINEERS INDIA LTD - (LIL)

CONTRACTOR | M/s» CORRTECH INTERNATIONAL PVT.LTD. - (CIPL)

HSE Officers Shall report to Project HSE Manager

Implementation of all safety recuiremerts cir

handling operation

Ensunng that the communtcation system is

working properly and thet emengency equipment is

place

£0 METHODOLOGY

GIPL shall facate & install the pipeline markers as per ElL standard d-awings: The

materials used ‘or fatrication shall be as per EI Specificatons. The location ot

markers shal be ‘inelizes in consultation with EIL/ HPCL. Care shall be taken whie

¥ location, 1 avokd Ne Waficipersonne! hindrances. Detailec tayout for

instalation of markers shall be prepared and finalized at site with cue consent of

EIL/HPCL Marker location shown in route/Alignment sheet drawings shall be taken as

guidance only and actual location of the markers shall be based cn the As ~ oulll

hainage ane as directed by EIL/ HPCL.

IPL shall prepare and submit the detei'ed ecneme for marker plates as applicable for

ihe project te EIL for review and approval. On lperoval ofthe scheme by EL. CIPL

shall febncate a sample matker for approval of EiL and upon approval of the same by

FIL, CIPL shal ication of the markers Painting shal be in

accordance with Cll > G-84.9004 and the scheme shell be sultabie

Narmel Comosive fn he pipeline markers shall be installed as far as

) possible al locations such that it causes no hindrance fo resuat use of land oF to the

traffic

The mode of placement of different markers shell 9¢ as stipulated below

4A) Aerial Narkers

Aerial markers shall be installed along the pipeline route in general at every § Km

ntervals arc or at places specified by BIL) HPCL. EIL standarc Drawing shall be

releeted for deteils. Refer Drawing Na 7-71-00" Rev 4 for cet

hall indicate cumulative distance in km for the refer

fy ElL If any pipeline waming sign falls in the range nae

not be installed. Refer Drawing Ne. 7-71-0008 Rev 4 for ¢

308 PROCEDURE TOR PIPELINE DOCUMENT NO.

NWARKER INSTALLATION ~ HRCI ER SCIP /eVPL Na)

PALANPUR VADODARA PIPE LINE PROJECT -PART-A

CLIENT M/s:- HINDUSTAN PETROLEUM CORPONATION LIMITED — (wren) |

CONSULTANT Mis ENGINEERS INDIA LTD - (EI (en)

CONTRACTOR M/s CRRTECH INTERNATIONAL PVT.LTD. - (CPL) — |

€) Pipeline Waring Signs

Pipeline warring signs snail in general be ‘nsialied al

«National and state highways crossings 2.No's min

+ Cther road crossings “No. mn

4 Rallway crossings 2.No's. min

+ Minor weter crossings (Less than 15 m wid!h) “Ne. min

+) Minor water cmesings (Above 15 m width) 2.No's. min

+ Mawr water crossings ? min

+ Valve station 1 No min

+ And at any otter location 96 shown in the approves drawing or as cirected

by EL /MPSL. Refer Drawing No-7-?1-00'? Rav 4 for cetails

nce of the pipeline and display the

The cipeline waning sign shal identify the exis

Company name with emergency telephone num:

D) ROU Boundary Markers

tof Use boundary markers shalt be installed at every 266 m interval, as per

9, along the ontire pipeline route and also at the tuming points to maintain the

continuity of the ROW limits. These shall be instalied or eithar side af the ripe ina

alig

Refer drawing no- 7-7

ment.

0099 Rey 4 for deta

F) Direetion Markers

Direction Markers. shal be ins: 6 Per

pipeline during anna! traverse Qne directic

int

Refer drawing nu- 7-74-0011 Rev 4 for di

ed fo identity the

on marker

significant Tur of the

shal be installed aback Turning

This wil be in

AH

| | 108 PROCEDURE FOR PPELINE | DOCUMENT NO.

MARKER INSTALLAT ON HPCL/EWL/CIPL/PVPL/MIL/JP-26

NERS

SON MID !

eho rea

PALANPUR VADODARA PIPE LINE PROHECT PART-&

© | M/s: HINOUSTAN PETROLEUM: CORPORATION LIMITED = (HPCL’

“CONSULTANT M/s - ENGINEERS INDIA LID - (Ell)

| CONTRACTOR M/s :- CORRTECH INTERNATIONAL PVT.LTD. - (CIPL]

G) Special Markers

‘Special rarkers shall be installed where change in thic diameter and “ype of

pige es uirecle /EIL It shall be epplicagie to other type of Markers except

dary marker © relative distance between ‘he two does not excaed 106

t

ig and stenciling for all the aforesaid shall be cone as indicated! in respective

standarts

All matenals for all

corosive enviranm

fof maker inclucing paints shall confi to normal

nforming te ag por EIL standard spec

nt ca

6.0 HEALTH, SAFETY AND ENVIRONMENT

# CIPL shall ersure that the fabri

+ PPE Is a must in th's activity

* Personnel araund the mai be cautious about overhead fall

+ During the movement of earth moving ecu pments the oprratar mus

cautia

tor must be an exnenenced persen.

¢ abjacts.

blow horn to

1e Peonte Around

© All Measuring & Test Equipments

= All lifting devices & Tails used 5

competent authority.

CIPL sha arrange Regular Too! Sox Meeting

© CIPL shall arrange First Aid Box at site

must be well maintained

nal! be well mainteined and aporaves by &

7.0 QUALITY ASSURANCE / QUALITY CONTROL

Quality Assurance will be maintained by systematic implementation of this procecure

and generating necessary quality records

4.0 DOCUMENTATION

ne Marker 17P 41918

F

on Test Plan - installation

n Revort

Pin

Ya aga

aseon between the above provedure and pruect spechieation the late’

ut any prejudice te We terms and consfions of the pontract er

gts

JOB PROCEDURE FOR PIPELINE DOCUMENT NO. REV

ee = Pape Tot

MARKER INSTALLATION WPCL/ENL/CIPLIPVPL/ML/IP 26 og | PRP

— or a ENCREERS

i 2a Sin ——

| ITP . INSTALLATION OF PIPELINE MARKERS

Jroiecr SALANBUR VADODASA PIPELINE PROJECT: PART-8 cove. fans

SEN M/s KINDUSTAN PETROLEUM CORPORATION TD. -(4°CL) -

LT FAS NDA ETD)

Joho ABE

vr a1D. (IPL)

Renords ta ba

soe semny cosmacine Bh Submimoezat

.

Sumas 8 epueval two # poceiue we fw | Aopieved etre

2 |Anorovel of © Samate* markers including painting we oe Soren

. SEC mahers a pes dang we . -

: pp

Ste anton snes an we

5 [Pre cating ot atta FOL founda mht wc s Pt worts

shatters Sm natn a ores enon a - » a

Ie rar |

# lbinertuctup. fash aining § slang we s oa

INsPceio s vLst oocuMENTS

4

‘Review tes! end insuectian documents: we

Wires ae 7 Rw” Review ot Contactar’ Gosursitaion ~~

$$ Suneitenen ‘We 100%. Sucanaion and Exar by Caarlor

4 spas Bon ee

ENCNEERS

NDI RATED

(ee

= INSPECTION REPORT : INSTALLATION OF MARKER

faa acs noone PRE PESTET PA Fett PE

Jenene M/s MINDUSTAN PETROWNN CORPORATION ITO (MBCA) [in Ne Aan

[CONSULTANT M/s ENGINEERS INOW@ LTD - (LL) — “Jaeport no. 2

[cONTRACTOR w/e CORTE INTERNATIONAL VT. LT “TOL bate

aigmemt sect No a

[section 4 re |Froe

beater Conditions _ tre a

wo gett Type ot Meter | Ne ot Markers Grtantaton memarts

—1-____|

Zummufati Prog

Previous Progress Today's Progress

PEL

(SaNED lsianen

naw anne

oer

loare

PROJECT PALANPUR VADODARA PIPE LINE PROJECT PART-A.- [P

CLIENT M/c :- HINDUSTAN PCTROLTUM CORPORATION LIMITED. -

CONSULTANT : M/s: ENGINEERS INDIA LTD. - (EiL)

CONTRACTOR I/s © CORRTECH INTERNATIONAL PVT UFO. (IPL)

[ LOI NO.: 17000045-0Q-10129 DATED : 04.08.2017

| JOB NO.: A848

'JOB PROCEDURE FOR

MAGNETIC CLEANING

PIGGING-(MGP)

PROCEDURE Na.: HPCL/EIL/CIPL/PVPL/ML/JP-27

M/s CORATECM INTERNATIONA

G CONTRACTOR [i Ms ATHENA POWER TECH LIP.

| LOI NO ; 17000045-0Q-10129 DATED : 04.08.2017 |

L JOB NO : A848

JOB PROCEDURE/WORK INSTRUCTION

FOR

MAGNETIC CLEANING PIGGING

DOCUMENT NO: HPCL/EIL/CIPL/PVPL/ML/IP-27 |

| DATE

10.11 2018)

TE PROCEDUREFOR REY Tape tof

NAGNETICC.EANING PIGGING [~~ HPEL/EIL/ciP.JevEL/MijIP-27 og] Paee tof?

ee Oi

PROWET [ :PALANPUR VADODARA PIPE LINE PROJECT PART-A

CIENT Mis:

CONSUITANT [i M/e = ENGINEERS INDIA (TO - (CiL)

CONTRACTOR [oM/s; CORRTECH INTERNATIONAL PVT.LTD. -(CIPU

‘SGT PIGGING CONTRACTOR

M/s: ATHLNA POWER TEC LL

CONTENTS

1 _* we

S.No. DESCRIPTION PAGE NC.

01, PURPOSE os

| 02. | score 03

03. | OBIECTIVE 03

D4. REFERENCES OF CODES & DOCUMENT

03

OS. BRIEF DESCRIPTION oaoa

“06, MSITE PREPARATION/BASIC REQUIREMENT FOR NGF 04

07. SEQUENCE OF OPERATION LAUNCHING OF MGP 35

08 SEQUENCE OF OPERATION RECEIVING OF MGP 0s

09. SPECITICATION OT MAGNCT PIG o8

_ 10, SCHMATCIE SKETCH CF MAGNET PIG oy

11, | SAFETY PRECAUTIONS DURING PIGGING o7

O72. | HEALTH, SATETY & ENVIRONMENT o7

13, DOCUMENTATION OO o7

INSPECTION TEST PLAN :- HPCL/EIL/CIPL/PUPL/ML/IT#-27 enclosed |

INSPECTION REPORT :- EILSCIPL/PUPL/ML/IR-27

JOB PROCEDURE FOR

DOCUMENT NO.

MAGNETIC CLEANING FISGING HPCL/EIL/CIPL/PVPL) MifIP-27

Enclased

PROLECT EPALANPUR VADODARA PIPELINE PROJECT PART A

Cant Iuiis - WINDUSTAN PE-ROLCUM CORPORATION UIMITEO

CONSULTANT 2 NDA (To = (ELS

CONTRACTOR TMS» CORRTECH INTERNATIONAL PYTATD. - ‘CIPU)

Rijs ATHENA BOWER TECH LL. (ATPL

Jeaning pipeing The puapose of this is te estab’sh

Ing IMGP) of newly co stiucted pigelines ta “ertove the ferwus

Vatoaare Pincline Provect (PAR~-A) af

Wim Corporation Limited, Construction Work, @y Ws Corriech Intervationa! Pra

This proced.re covers the vechnitel & general requirement and the apotication ct the Magnetic Clearing

Piggine - (MGP) form et Despates terminal (9) at Palereur ang Varicus intermediate faclities suc’

Sectional ng valves {S¥iand intermediate Pig ra Pineline Proje

3.0 OBJECTIVE

The objective of re presen: survey is of the pipeline and obt

the recard of internal geometry In "As leie” conditia ofthe pipeline: ts therr‘ere required to run the

megnetic cleaving pig and Mectronit Geomety Sg (EGP! entity, craracterize (S2ing and

lacatice] and evaluate anv peometrical injuteus defee's that might have gol introduced during,

lnsalation

40 REFERENCES OF CODE & DOCUMENT:

ARGS 019-07-4126P-0001 | Specification for Magnetie Gaming & GP

AP a404 is Jelding of Pipelines andi Related F

aSWEB SLE [Pipeline transoertatlon Systeq for geld and Sullrer

osiostD 141 Design, Construction and Inspection Regulremert ter Gross Country Uguide

“i Hydrocarbons Pipelines.

5.0 BRIEF DESCRIPTION:

aring the construction ef new ipetines, debris/tareign mateiial such as sand, stones, pieces. of

metallic dust and stee! shets etc. wil invariably be le ov: insice the pipeline. All of tvs fore

material chal have to be removed prior te launch cf Caliper | Liectronic Geometry

For gooe Inspection ress ‘riporte at vat pipeline shell be free ftom all kind of foreign materia

including the ferraus ders. Accordingly, after successful com pletion of the clezming gigs runs, Magnetic

cleaning vig carviee gut in nipeling to remave the ferrous debs (Debs shoul not be more than S0

rams/kin)

The Magretic Cleaning Pig is = 61.0 Pig Fitted with a number of powerful Permanent Magnets of suitzble

sige ane strength, crcunéerentiatly on Its Sody. These Magnets are located an the Pig Body ir such

fasnton thet they re ran iose provinvty to “he pite ire wal

During Magnetic Clean og ging Operathay, the Waghets mounted on the Magriehiteaning Mig caoture

9) *he residual Sompgugdabrs fro: the pipeline anc carry along to the Recver Rane

ee eee | SaRETEEE

ee meres

{EFALANPUR VAGOOARA PIPE LINE PROJECT -PART-A

IN PETROLEUM CORPORATION LIMITED -(HPCU)

iota 110 — (Ch).

EONTAACOF M/s CORRTECH INTERNATIONAL PUT LTD. - IPL

SGT PIGSING CONTRACTOR [ M/s. ATHENA POWER TEC LAP. (ATPL)

he amourt of debris rece'ved atte: the first -un of Magnetic Cleaning Fig is

for @ repeat “un of the Magnetic Cleaning Pigging, The repeat runs ef Magnet

ecuited h time the ferrous debvs “eceived if reeuced within

etal ¢ of the Magnetic Cleaning Big are given senerately in the acta

ree we may have

Cleaning Pirging

The

6.0 SITE PREPARATION/BASIC REQUIREMENTS FOR MAGNETIC CLEANING PIGGING

The folicw ag site preparation basic

M/s Covrtech Internationa Put. itd”

‘guirements shell h

De arranged by the pizeline cort

factor

> Ay

ity of at least 3 Nos. of Compressors. (2 working! 4 stand2v} cf suitable Capacty

(>> 1290 €5M& pressure range ua ta -€ bet) on each -auncher Location,

5 Sermanent ov Temmmorary Launcher & Receiver of 4 suitable site anc Leneth {Straighe

Barre! a 2000 mm long) can rected to the mala [ing

> Tersperary Launcher wit a proper Door Closure, connections for compressor) Air Inlet [4

Nos, two near the closure and the twa on the reducer! packnes for Ine packing ard *he

Bech Pressure

% On the Launcher Berrel, 2Nos Dia 1” Tappirg with s terparery Hose Conrectier and a

Ball valve {at ahovt 700) 300 mm distance from Launehe~ Door! Flange eré anc at about

ang/S00 mes frors the reducer enc on the main pipeline] for pressure ecualseticn during

} tne pa: 1065 0F pipe ine (Selienvatic drawing aitac hed)

} Receive on the ether ene of the plpetine section shel. also have a nroner Door Cesure,

i sitable connections fer the drain ang the vent-7 Nos. (Schematic crawing attee'ved!

¥ Both, the Launcher & the Receiver shall be fitted with she Pressice Gauge of 10 kg fen

Pressure Range {callbvated et 2 time o7ly!, On the launcher barrel, tnere will be two

pressure gauges wict wit be mounted ag under

cistance of about

: neta

___ BOCUMENT NO.

—— _ 1

EON | copes | Crust,

|: FALANPUN VADODARADIFELINE PROIECT PART.

M/s. HINGUSTAN PETROLE ALIGN IF

/s ENGINEERS (NoIa LTD (EID

CONTRACTER [iw/s. CORRTECS INTERNATIONAL PVT OTD

S67 PAGING CONTRACTOR | Mis ATHENA POWER TFC LIF (ATO)

7.0 SEQUENCE OF OPERATIONS CURING LAUNCHING A MAGNETIC CLEANING

The various steps involved for the Tool Launch Preparation are as ender:

The launcher ehall be Cearescurited and shall be made emety for cutting Magnetic vig

The Launene! ac: ct the launche- is ther axered; the Magretic cig toe% rlacee insice and

pushed adeouately te "each the tool at the reduce

The pig rust be pushed in her such thet she ‘rent dives of the pig are pushed

the launcher barrel

Clese the Lawacher Una Flange propesty

jose all the valves or vert cr drain connections 09 both eres ian Launcher & Receiver}

Cpe gure ecualizing valve mounted on the ecualizatina nose/ aide conn

ro the front & bach af the tavl pesition an the launcher barre. ace start the Compre:

for pipeline packing

Pack she f ne with alr pressure up to 1.0 kg/cm? (Io case of magnetic pig “un, the Ine

jerking rev be increases’ or decteased based an site! p re

Shut-off the comaresscr valve once the pressure in the pipeline is stebillzed at 10 xglem2,

art Compressay Na. ? connected fe the .auncher Barve! at the beck of pig in order to

sale bac pressure, Also, at the same time close the ecuel zation valve mounted an the

hoses pipe eaual’zing the back pressure on che trot and backside of 109)

Pig witl stars moving fravr the launcher immveeiately zfter the back pressure or the beck ef

tool exceeds pipe'ine pressure

Pig will tart moving frovr the launcher immediately efter the back pressure or the Sack of

too! exceeds pipeline pressure.

Ogen the vert valve an the receiver berrel slowly and a differentia! pressure cf 3 kgiem?

should be va ntalned

ng the pig ran, the alt “low will have to be contralied so that he velocity in the sange

prox 03-2 mye (i-€ lenshr] The mavement cf pig can be tracked at seme ore:

determine lacatior! iacvax.20 km. inteivel) on the entire route a7 sipebae

108 PRICED —nortiwent we,

MAGNETIC CLEANING HPCLELCPL/PYP LP EOL hg PaRe Set 7

MB ENCNRS

oie TOKLMT | Eeeneen

PALANFUR VASODARA PIPELINE PROJECT PART.A

i Ms: HINDUSTAN PETROLEUM CORPORATION LIMITED - HPC]

TEONsuLTANT M/s = ENGINEERS (NDIA LID -

CONTRACTOR Mis CORRTECH INTERNATIONAL PYT.ATD, - (CIP)

SET PIGGING CONTRACTOR | Mfx.- ATHENA POWER TECH LP. (A7PL)

7. SEQUENCE OF OPERATIONS DURING RECEIVING MAGNETIC CLEANING PIG

The various steps Invalved far the Toa! Receiving Preparation are as under

The moment slg reaches the receiver be-rel, ensure ks location using Pig Track ng device

Only afer i is cerfirmed thet the Pig Sas reached sight inside the Receiver. ciose the a'r inlet

Va've and ston Compressor

Start de-presswizing tre aige!ine by opening vent valve 21 the Recewer or ava'lacie, at the

other locations en the pipetine fnc'veing Launcher

Once sresture is recuced to 2e°0, looser balts an the Kecewver Door Ir crde*to vert aut the

trapoee 2

Omer the Recewe only after It Is conftemee’ that the trappec air fully ecvaped from the

pipeline

After Cpening the Receives doo", take out! removed the pig from the receiver bavel

Shit the pig to cleer area In the vieinty te study its overal 7 and to assess the

ariourt ot fe-reus cei rece ved.

Collect a the ferrous debris from she miggyets mounted around the pig end weigh ir erder to

assess rhe svitabilly cf piaeline w rt, tie permissbbie iim

1h case of ferrous de bis received is more, the re-run of the Magnetic Clearing Pig has ta be

caer ot! until such time the ferrous eebr's Is “cCuced te requ red |

le permissible limits of ferrous debris, clear the Pig and teansport i

heck to a safe storage are

Specification af Magnet Pig:

net Cleaning pig consist of & Nos, of magnets (Permanent Magnet] equally

buted and mounted on Pig body.

ef cleaning pig siralt be used with BDI configuration (2 Guide dist wilh 4 sealing

Mepnetic clearing 2g configured ina single module an¢ total length shell be (Equal to

1.SE] ard approximate weight cf too! shal be 95 Kes.

Magnetic pig can abe to negatiete 1.50 Bends and can past sh-ough reduction Unt

20% of 1D wthout damaging cig end give

Fach magnet

SOCUMENT NO. iz, rod

EPCL/EILICIPLIPVPLIMG ORT

ENCNFERS

ROAM SREETERH

[PALANPL VAGODARA PIPE LINE PROJECT -PART.&

t/s HINGUSTAN PFFRDLEUM CORPORATION LIM'TED_(HPCi,

CONSULTANT _ M/s | PNGINFERS INDIA TTD - (EIU

CONTRACTOR, EM/s © CORRTECH INTERNATIONAL PUT.LID. - {PL}

SGT RIGGING CONTRACTOR | = M/s:- ATHENA POWER TRCHLP. (ATPL)

7.4 Schematic sketch af Magnet

ra Saf

Precautions during Pigging

SP Operation chal be instructes on possible dor

5. However the follovnng Points are ta be sper'ally pxnlained to all manorws

Al) persona working 99 the vectee with pigging

& with aressure air operation

betore starting af Figgiag Onerat

auncher /Recelver Closures ar Binds

Fneure that 2ipeting

‘ompletely depreesurized before opening c

af temporary hescers

sure that al Iscieting Mainline Valves in the Pipeline, exept auncher isalating valve are completely

aen before launch af Pgs

ve that all By-pass tn

lating Valve, (except at Launcher ixolating Valve) are in clased position

4, Ensure thet ali inescannectes with Pipeline are isolated te ovevent air / mediu te escaze outside the

pipeline circuit

sure the! suflcient area Is available for dispasal of Debris / Water received with Pig from the plneline

8.0 HEALTH, SAFETY & ENVIRONMENT

= During MG? opera

lon, special cave to be taken to avoid personal iniury

+ Machine operator invalwee shall be an experienced pe

= tPF shal be

ed in this activity

= Only trained gersonne! ta be deployed for this activity

+ bl essuring & Test equiament vse shall e wel! a

+ Alling devices & Te ls used shall be woll maintained

3.0 DOCUMENTATION

0 ~_SESCRIFT DOCUNENT/FORMATNO. | REMARKS

1. | INSPECTION TEST PLAN- (TTF) HPCL/EILICIPL/PYPLINL/ITP-27 Enclosed |

2_ | inspeeriey aeronr (1) HPCL/EIL/CIPL /PVPL /MA in 27 Enclosed _|

(Agus O10 UL Biron

Nete In case on any confit between the above procedure ang polprt spnctficationkive later Rovio)

shall govers, without any prejusice to the terms and condition af the Centract

vay

Ly

MAGNE ATER i

Save

76 CRAB IONS,

ON) S24

tha 10m,

Towne wer]

on)

von

wea]

IVERIN HoLeHOD TN

THEN

ANWATD DiLSNDY

een

Big SHAUBEN 70 22ue237V|

aaa aaa

ef arm

ran ang

Prem)

copeaig Busted

waria =A

sossaiewiwoo|

[eel uote

‘Wales aouses)

wera won|

WoL WalnoD SmbSaa 155

ve wnswon}

ana

ang) Lo!

or ae

| INSPECTIN AND TEST PLAN : FOR MAGNETIC CLEANING PIGGING -(MGP)

cor PAANDUE VADOOARAIPTLNE RORET_PaRToR Tremaine rha/ioryevesnajieay

a

leona Sones sano a -

komnnor smmnom DTS ERT Tanna

ee I

_. ~ verve) erm een

oe — ebm win ween ea

7 osm wreners epee Syme) wenn

oe rgeorneano oe : :

& centingot ante ~ | fw

7 won nvhiwes noe ewe | woe rena

oe few mint neem > Powe fo

om few musi we | fester ari

te unaom

ew" RUVIEW OF CONTRACTOR'S DOCIMINTATION

8) SURUELLANCE INSRrETION RY OMMERY EL

eT 1a EXAMINATION BY CONTRACTOR

‘CHECKED AND VERIFIRD BY

fs caTeL

Si

‘ane

=

vay

PROJECT [PPALANPUR VAGODARA PIPE LINE PROJECT PART-A_ [PVPL)

CLIENT Is HINDUSTAN PETROLEUM CORPORATION LIMITED.

CONSULTANT GINEERS INDIA LTD. - ¢E1L)

CONTRACTOR CORRTECH INTERNATIONAL PVT.LTD - (CIFL)

LOI NO.: 17000045-0Q-10129 DATED : 04.08.2017

JOB NO.: A848

1

_JOB PROCEDURE FOR

ELECTRONIC GEOMETRIC

PIGGING-(EGP)

| PROCEDURE No.: HPCL/EIL/CIPL/PVPL/ML/JP-28

LOLNO : 17000045-' 0a 10129 DATED | D:

| JB NO: ABas

fi

JOB PROCEDURE/WORK INSTRUCTION

FOR

|| ELECTRONIC GEOMETRIC PIGGING

— HPL ETL Sues

| eROIEC PALANPUR VADODARA FiPE

CUERT ies

CEONSULTANT NGINEERS INO ATO —(F'L)

CONTRACTOR IMF CORRTHOM INTERNATIONA TTD. TPO

SGT PIGGING CONTRACTOR | : Nis: ATHENA POWER TECH LL®.- (ATOLL

INDEX/CONTENTS

DESCRIPTION PAGENO

PURPOSE a

03

03

REFERENCE OF CODE B DOCUMENT 03

PIPELINE SECTION DETAILS 08

PREREQUISITES 04

CAPER SURVEY

DETAILED PROCEDURE

INFORMATION RETRIEVAL

_REPORTS

TOF FEGLIPNENTS, TOOL & TACKLES

SITE ORGANIZATION CHART CF TOW

RESPONSIBILITY MATRIX

SATETY PRECAUTIONS DURING CALIPER PIGGING

_ DOCU ENTS/FORMATS

__ANNEXURE 1 TOOL/DEFECT SIZING SPECIFICATION DATA SHEET Enclasee

Enclased

INSPFCTION FST PLAN HOCL/ENLJCISL/UBLIML//T P27 Frelaed

LT INSPECTION REPORT

SITE CHEKLIST TOR CALIPER SURVEY - HPCL/EIL/CIPL/PYPL/ML/ITP-28 | Enclosed

PRELIMINARY REPORT. ~ HPCLIEIL/CIPL/PVPLIML/ITP-288 Enclosed

DEFECT VERIFICATION SNEET___- HPCL/E\L/CIPL/PVPL/ML/ITP-286. Enclosed

FIG TRACKING REPORT Enclosed

TRACKING RI __- HPCLIENLYCIPLIPYPY iL

Sy

108 PROSSER

ELECTRONIC GEOMETRIC PICGING

]

Ree MD §SRRTESY Pewetteet,

“ PALANPUR WADODARA PIPE LINE PROJEC

M/s: HINDUSTAN PETROLEUM CORPOR)

M/s ENGINEERS INDIA LTD (EI)

- M/s CORRTECH INTFRNATIONAL PUTLTO_-(1PL)

(GING CONTRACTOR |: M/s: ATHENA POWER TECH LLP. (ATPL)

A, Caliper Pigging (Standard Geometry Pigging)

1.0 PURPOSE;

leeivonie Geomet-y Pigeing 'scartied out ta accesé the interna: geameiry of the pipeline, The changes in

the internal diamete’ of me pipeline C2usea ay overibes, Gems, changes in wall znickness, perislly closea

velvet end the location of these defect are detected The measurement covers the entire 380 ciagrers of

interna pipe wa! circumference

2.0 scorr:

ig Procedure covers the work methodology for running Standard Geemettic Teal Mgging (SGI/CALIOER

Pigeing) a aineline construction 9 . 3 Pipeline Project (PART A) of M/s: Hindustan,

Posreleum Cotgoretion Listed. Construction Work, By M/s: Corrtech loternational Mt Utd

3.0 OBJECTIVE

he objective nf the present sunvey is te clean “constructional etal dehrie’ of the pipeline and ntain

the -ecard ot internal geometry in "As laid” condition of the pipeline. it is theretore required to run the

cragnetic Vleaning pig and Electronic Georret'y Pig. (EGP! 30 a8 to identify, characterize (Sizing and,

cation), and evaluate any geometrical injurious detects that might have got intraduced

4.0 REFERENCES OF CODE & DOCUMENT:

A848-G20-02-42-E6P-0001 | Specification for Magnetic Cleaning & EGP

Pi L104 “Standaré for Welding of Pipelines and Related Fae) lities

ASME B 31.4 Pipeline Transportation System far Llavid anc Sullries

Design, Construction and Inspection Recuiremert far Crass Country Liquids

O81. $70 141 Hydrocarbons Pipelines

5.0 PIPELINE SECTION DETAILS

Besription 1a

Pipeline Sectors 128

Sineline Diaveter 18" (Shame

Pipeline Grace (APISLGr.X-70

Romina’ Pioeltse Wali i

Thickess (Minimum)

Pipe'ine Wall Trick

(Maximun)

2am & 874m,

sai my

>

\

{4 _ f _

105 PaciREMURE OR LT 0 iv _| Page No.

[__necrsontc er DaeTam EH ina! aot 09

—— oo

=e Shea NERS

ee eft NDIA MTA)

PROJECT

‘CLIENT

CONSULTANT ENGINEERS INDIA LTD ~ (F

CONTRACTOR {vie CORRTECH INTERNATIONAL PYTATD. [GiPE)

SGT PIGGING CONTRACTOR "ATHENA POWER TECH (LP. (ATPL)

6.0 PREREQUISITES

Cal per (FOP! P geing shell be taken up after Hydra testing, Dewetering. Brush pIEgINg. Mapnet'c olgging

and ie in ofthe Pyére test Sections ta the rreuired Calizer pigging sections The olpeline section shal be

cspect Launcher, teeeiver ana other pineline features enc shell be carrie out prior to the survey

‘The Leuncher/Recelver snou'd be designed 10 atcommocate Standard Geometry Toe! - minimum length of

roo! 's 3 m approximate. (Piease refer specification or catact ATPL)

7.0 CALIPER SURVEY

The Calige’ (CGP! pigelng for the ebove section sha'l be nevtormec by using compressed air 3s medi with

re nacking of alv et 4-45 bar aressure. Te enable launch Calpe: pig sultab'e launcher/receiver shall be

provieed at site

Refer attached SGT toc! specifications for the SGT Too! that shall be used for the survey.

The Caliper Survey shall corsist of rurning ane Stancard Geometry Tao! (SGT) along the Pigging Sect’on

Length as stated above

The Standa-¢ Geometry Too! Pig corsists of

Polyurethane Conical Cups mounted en front and rear of the tool.

Finger assemblies (16 in nes.) Tcunted on SGT body. The finger assembly scans the entire

egieet of the Pipeline for “reasuring the internal geometry af the Pipeline. Tre Angers

mave due to change in internal geometry of the oipeline. The reverent of the finge's Is

onical yt der through sensor

Two Odometer whee's grovidec at the rear end ct the tool measures tne linear cistarce

travellee by the tool The CPU onboard records the movement af the finge's and the linear

movernert cf the tee!

SGT oo! equipped with Battery pack at the front which has Lthium hatteres, The

life of the Battery pack is 00 Hrs, (Exte ndedt un to 200 Hrs.) for this specific toa!, Additional

battery packs may be 2eded it the sectional length is long and calculated travel time of the

too exceeds the standa'd battery pack Me

5 Pig Track ng Trancmitter is housed at the ‘rant of the tool and Lses the other Battery source

18" Caliper tool fs capable of negotiating min'mum 30 bends ard can run in the min-mum bo aight

pipe at 342 mm and minvrum bore in 3D herds of 380 mr

Tre travel Velacity 0° che tool at Pye above pressure will be 1.0 S.C m/s and ths shal! be maintained by

adjusting the backsressure ta 4~4.5 bar using 2 compressor 1200/950 CFM capacity,

During (he ig wun zhe eressure is recorded atthe faunching and receiving location by using pressure

108 PROCEDURE FOR

FLECTROWIC GFOMFTRIC PRGING

| rit Re he eS eqneens | Oem.

| SGT PIGGING CONTRACTOR | M/s

lL. |

PROLECT PALANPUR VADSOAWA PIPE UNE PROWCTPARTA

CUNT mi JOLEUM CORPORATION LIMITED {HPCL)

CONSULTANT M/s ENGINEERS INDIA LTE - (EIU)

CONTRACTOR [EM/s : CORRTECH INTFRNAT!ONAL PVT.LTD. (CIPL)

= ATHENA POWER TECH LLP. (ATPL) J

8,0 DETAILED PROCEDURE:

8.2 Pig Launching

The $G7 too! shall be launched an satisfactacy tecords shown at site that the gauge Dlg

un was satisfactory and the magnetic & Brush cleaning run iscomplete and satisfactory

+The Celiner Piggiag shail be cetormed usirg compressed air a5 med'am with Prepack of

airin ont ofthe pigto he é 4 Sher

4 Themain ine veive at the Launcher ene snow closed, *he launcher shall be

cepressurized and shall be made empty for putting SGT too!

4 The closure door ofthe lauricher is then opened; the SGT too! plac

adequately a reac the toa! at the recuce

4 The auncher closure door is zher close.

Je means of vor unication, the technician af (he receiver end shall be infarmest

1 pig is ready zo be launched

+ The Pressure shall be balances between pipeline and avncher barrel across the Main ine

valor with beie of preset balancing Ine

4 New themain ine valve atthe launcher is stowh enened.

+ Start the cempresser with connections at the back ofthe pig using Kicker line. The volume

aed pressure behind the pig wil drive the pig frm tha faxcher

inside and pushed

42 The launch of the pig frore the launcher tmarrel ig caoFieed by a alg Indicator indication

cov wits the hela of the receiver of the APTL Track master taal

82 Pig Tracking

Pig track’ng sha! be carried ou! during the SGT tea! tun by using Track master af minimum 5- 10%:

tecvalt and sien at every possible location

Pig trecker cers!

plectromagne:

of a transmitter and receiver. The transmitter is fitted in the pig. The transmitter gives

« pulses, which are ceceived by the rece'ver

Theve shall be two)

ching Tean depioyec tor te taking of the pig tool 1 Receiver is used to track the

Calive aig on the grounc, When the Caliper pig passes the First track point, the first recelver is shifted to

the third track paint Similarly, wher the Caliper pig passes the second track point, the second receiver Is

ch fred to the fourth track point The preceture thes repeated til the pig reaches the reraiving paint

nts, the location of the stu

the pig's stuck in between two tract

these swe track aims with the receivers

A pig s tracked by walking along

The stuck pig ig then removed by cepressurizing/draining the pinetine, cutting the pineline section and re

with a pre tested pine of reaured length. IF Fi

cl with the same Sroresure

J datas net ford satisfactory then a re

iefore convnvesioniag, Stick Pig removal pro:

Should the p'g pet stuck In the line then th

2 |activiies velated to retrieval ef the:

TOs PROCEDURE FOR”

ELECTRONIC GEOMETRIC PIEGINA (2

eis ENGINES.

anes) FOERTER

Paar “GALANPUR VADODARA PIOF UNF PROIECT -PART-A

“quer ifs HINDUSTAN PTROW ETM CORPORATION civtTEDAHPCL)

“Consutta Dis ENGINEERS TSAO EH)

[eotaacton

Ser rigsine COMTRAGTON

8.3 Pig Rece'ving

rece pt of Pigat the reueiving barrel [confirmation of the same is received by a pig Cetector at the

vecening batrel c+ by checking the seme with the receiver {Track master] by plaving it an the receiver

barrel) On receiat of confirmation of the SGT tot being insite the rece’ver barrel the main line valve

‘Toe receiver barrel is then de-pressurzed drained and the closure door Is egened anc the SCT tool ic

‘vedi. A ahotogreph of the pig as recelved is taker

The date and time for the receipt of the SGT Too! s recerced in the sultabie format available with the

Engineers and vaproguced in the jwellminary report. Sanvple formats are attached for reference

2.0 INFORMATION RETRIEVAL

The data roliecter by the Si Fa ic retrinved hy downloading the data tea portable work statny by the

echrican, Standare Geometry tool shou'd detect minimum 2% chenge af ramins! pipe dia. and acvsracy in

detection of fengtt of defect should be © a ram the nearest permanent features ike valves, tees, hemvy

{alizer pigsine will measure bend radias an6 hend angle from launcher to Receiver Complote data wil be

detected! fom Launch: ta Recelver

oicase rer attached Toe! Infarmatior far taal capabilities

10.0 REPORT

‘The reports shal include the aerameters of permanent olpeline features such as valves. hemwy wall pines,

connection, Weiding nits Gite Weld & Tap oF etc

10.1 Pig Receiving

The record ng of the SGT pig anslyzed for defects equal to & above 5% and recorded in approved forinat,

oe a preliminary repert shal repar defects equal to & above 596 cf Internal Diameter and shall be

furniched ovradiate'y after the ST pig wun withir 28 Hrs,

10.2 Final Report

The Fina ceport shall neport detects above 2% of Inte-na’ Diemeter with detalied ana'ys's and allthe

Features ac minimim as give in contract specification (please fing below table for the Feature! shall be

fumished in one Hate and one $9"t oapy afler about 78 ["wenty Fight}working days by ATPL

“peat ete]

devia Site Minima ee TH BETS

Out ef Rauneness, |

ELECTRONIC GEOMETRIC PIGGING ZS

aegin NMED |

PALANPUR VADODARA PIPE LINE PROWFCT

_CUENT, _ US : -BINDUSTAN PETROLEUM CORPORATION L INITED,

“CONSULTANT PVE ENGINEERS IRDIALTD UF)

“ONTRACTOR fe CORRTECH It ;ONAL PUT (avy

‘The Fins! repnrt wii refer to Cllant!s requicement It shall contain the following

beecutwe Summary

Geometry Summary Report

Dert = Detect Verification Re

Pipeline Suminanry Report

Dert Nepth vs. Oktan

Dert Orientation vs. 0

aol Velocity vs. Distance Graph

Number of cvalities

Orientatiant plot of al dents over the ful pipeline length

vvvyyyeyy

Confidentiality

AYPL shall Kean the inspection report stretly confideatial following the inspection survey and under no

circumstances wil make It avaliable toa third party without a prior written censent of CLIENT

12.0 UST OF LQUIPMENT. TOOLS & TACKLES

1S°CALIPER Tan 4 Nes

Tools Boxes, Mobile Phones etc

7700 CFM Alrcompressor(s) 2 nos. (by CIP)

Pressure Gauges ~ ? Nes. one ech an iauncher and recetver {By CFL]

17.0 SITE ORGANIZATION CHART OF ATPL.

DOCUMENT NO

Jeu Gri fowrjneijie-27

Pest iw | Se

:PALANFUR VADODARA PIPF LINE PROIFCT PART

rotige for yaa

__Man pawer &St1 tool to site

ian

Local tabor for barsel ope ratinn, too! handling and

Arrangement of pre-caliper suvey meeting with

Gent Running of tan), Tracking tacetions ete

[paging & unloading oF all S67 Yan’ ane! algging

equiptent’s

Arranging 6f saork parti fram CIPTPEBST

Pre packing of pipeline to 3-4 bar aressure before

launching of caliper taol to ensure eerstat ve‘gcly

oF SGT Toe!

ansportation of APTI ew at site

Propelling 9*SGT celige! Toe using required "a

concitons i tre piseie & re! taining £9-0UR ut

the olgring

Operate . 8

Suiomission of Preliminary Gallaer survey repact with

43 Hours, after Completion ef job

‘Submission of ceteled Celiper suvwey

Report within 28 cays after completion of job

Re vur # equ red when rot meet

speciteations.

Documentation and Anal ce here

teports ana photograzhs

Verificaticn- ATPL shal provide cetals on dig

o>. IPL te.carry out physical digging an

_chees in Presence ef ATPLIHPCL

| Safety Attachee

WECM aT

Page No

Ls of os

_ CONSULTANT M/s ENGINEERS INDIA LTD — (EL)

CONTRACTOR EM/s - CORRTECH INTERNATIONAL PVT.LTD.

Sar CENA COMTAACTOR | EM/e:- ATHENA ROWER TEC LLF (ATPL)

T

Sa NTE 3

Sats eNAIMID = = EBRNTESR | evertee,,

ne porte es

“FRORGT {PALANPUR VADODARA PIPELINE PRO.EGT PART-A

CLIENT :Bi/s :- HINDUSTAN PFTROLEUM CORPORATION LIVITED (HPCU

44.0 SAFETY PRECAUTIONS DURING SGT PIGGING:

+ AY personal working for the Pigging operation shall be structed an possidir cangers

connected with pigging by use pumps In addition, these instructions are to be spec!

exolained ta al the manpower before starting of pigging Qveration

Al personel shoule have complete PPE reauired for the job Safety Signs and tars to

at process area. at beth stations

It shall be ensured that the layicher / recciver barrels are completely d-sined betore

‘pening of launcher/receiver closures ar blindy of temmacrary heatlers,

1 shall be ensured that all (solating mainline valves in the pipeline are completely opened

betere launch of pigs

1 stall be ensured that all by-pass lines et ‘soleting Valve, (excert at Launcrer ‘so'ating

Valve) ate in closed position

Il be ensuree that ali ines connected with pizrline are ‘soiated to prevent press

alr/propelling media to escape autside the pipeline ¢ ruit

|r shell be ensured that sufficient area is avaliable tor d'sposal ot debris) water received with

fig from the pipeline

DOCUMENTS/ FORMATS:

eae S/eQuNaTS _

ANNEXURE 1: TOOL/DETECT SIZING SPECIFICATION DATA SHEET Enclosed

STUCK on oink - a [L_ freiosed

INSPECTION TEST PLAN & INSPECTION REPORT

INSPECTION TEST PLAN | HPCL/EIL/GPL/PUBLINL/ITP-27 — frciosee |

INSPECTION REPORT

SITE CHOC st FOR CaLipeR SURVEY HPCL/FiE/ciPi/evPLMT 28 nase

ORFLIMINARY REPORT HPCA/EIL/CIPLIFVEL/ MiyIRP 288 Tae

OEFECT VERIFICATION SHEET HPCUEIL/ CIP PVPLIML/ITE-285 aN

BIG TRACKING REPORT HBCL/EIL/CIPL/PUPL/NILJITP-2RC

bp

Nate : In case on any confliet between the above procedure and project spectficalaithe late/

shall govern, withovt any prejudice ta the terms and concitions of the contract

wavemonk Of EX. syPook Hl ABUB - ae Yok

90: Revo we dow chad botedl Qupsel

“_ BOCUMENT NO. REV Page No,

HPCUFIYCIPL/PUPL MAL fF 27 90.

ion —— T

| es EO | Sess stile,

nora FALANFUR WAGODARA PPE LIN PROMECT PART

Ctuen [Eis HINDUSTAN PETROLEUM CORPORATION

CONSULTANT M/s ENGINEERS INDIA LTO -(CiL) _

| conrkacran [M/s = conaTeCh INTFANATIONAL VETO. (EF

I Ser GING CONTRACTOR M/E ATHENA POWER TECH Lp. [ATP

SITE CHECKUST FOR SGT SURVEY

[facva te Ree ER Teper

Rey 09 bee

Description of Checks

ty)

ite as per procedure

1p Crew are avallab jeatsce e #8 per oroet

cauncher and Receiver

Pressure Gauges

oeding and Unioading of the ig Taal facility

Lighting arrangement

Operating Conditions of Pipeline {Pressure & Flow)

Communication Network

ccors [Required cepacity

armani ching R Recciving Station

person

Tracing fear and pipeline ove Ween

king coints identifed OSS

wo tor

+

“ite NKMO | SSeTSSA fae,

TpRLANPUR VADODARA PIPE I

Mis. HINDUSTAN PETROLEUM CORPORATION (ON UMITED (HPCL)

[eonsuirant LM ENGINEERS INDIA LTD = (EI)

CONTRACTOR M/s CORATECH INTERMATIONAL PVT LTD. {CIP}

[Set piccine contaacron [_M/s)_ ATHENA POWER TECH u.- (ATPL)

} - PRELIMINARY REPORT

} Fara Na (APE a

[sate

orscnpTion

Receive time ang Date

Joo! Aun Time

Average Speed of the S61 Taal

Location Of Detect Gefert size Remarks

THE DATA RECORDED ARE INTERPRETAPLE AND GOOD.

"a2 [THERE ARE REDUCTIONS FOUND ABOVE 5% OF PIPE ID)

| 92 _INERE Age OTHER DEFECTS NOTICED.

ote: ee4o/t8 ane to bs ancioced to tls report 2 and 3 are “yes

FINAL REPORT TO BF SUBMITTED RY

REMARKS:

AFFRCVED BY

NAME,

Pea aA

Se oe a

seuane SES a

pate =

eee

A aye wars

eee hin

[sive Hin OLEUM CORPORATION UM

[eonsuirane Mis ENGINEERS NOIALTO -(@l)

TRACTOR M/s” CORATECH INTERNATIONAL PVT.LTD. _{CIPL’

[SGTPIGGING CONTRACTOR M/s: - ATHENA POWER TECH LLP. (ATPL)

DEFECT VERIFICATION SHEET

[FormatNo._| :HPCL/EIL/OPL/PVPLIVL

| Pipe Dia

‘2 _ Start Polat Chalnage

a3 End Port Chanage

04 Total Length

Type of

Detect Size

| Detoct Axial Location

| Defect Radial Location,

| The cancted Select has been verified after excavation and following ebservations have bees: made

"Ivpe of Defect

tect Site

Defect AvisiLeeation

Getect Radial i

REMARKS:

ATPL

are | REVISED BY L

PREPAI

cuent

(eONSuATANT

CONTRACTOR CORRTECH INTERNATIONAL PVTLID.

[SGT PIGGING CONTRACTOR TATEENS POWER TECH IIP,. (ATPL)

BIG TRACKING REPORT

WPCLIE/EIPL/OVPLMAjIR DRC ——~*ds Rep e:

“ate:

18° Wain Line fo: Palanpur- Vadodara Pipeline Project

Hinduster Petroieum Carporatlon tinited -(4PCL]

Cortech Int. Private Lite.

SGT Pigging contractor M/s.~ Athana PowatTach LLP

.SR.NO. | DATE Time _ OPERATION PIG LOCATED AT CH

Saar NTRS i

Bales NAM CSRRTECH Bnlteen,

TPAIANPURVADODARA PIPELINE PROJECT

GutN) A/a :- HINDUSTAN PETRO\EUM CORPORATION LIMITED HBCU)

‘CONSULTANT rales ENGINFERS INIA TO (EL)

conreaciea Liye congir ox ntemuaTionaL Pvr1TD. fer)

SGT BIGGING CONTRACTOR M/s: ATHFIVR POWER TECH LAP.-(ATPL}

INSPLCTIN AND TEST PLAN : FOR ELECTRONIC GEOMETRIC PIGGING (EGP)

[it wo: HPCL/EN/OPLTPVEL/NL/ITPE “Date 102 2018

sun bowen Trapecion By Recoronta Be

ity Deserption HTT ted) Faves No.

Calioration of EGP Tool W__ Cakbration Aepor

Submission ofTestCer.Of R ‘est Cet. OF Pig

EG? Tool | Manufacture

Ensuring Commnnscatioa RN

System

Caliper Survey w w

Too] Run

hing Check of EG w

el

Loading af Siandard Geometric RM.

w

Report

Detect Venification

Final Report

W— Witness

R ~ Review Docume:

A= Approval

RM -- Random

Perfor

AME

SIGRATION

IsiGNATURE

inate

£GP Calibration Test Report

ICETTFICATION NUMaRR — P2p-$G7001-F27029-ATH

scmer Narve lustan Peirc 6ur1 corpordtion inte]

Reietivee ia Standard Geemetn 601

Bae Tsai

(Asser 8" TOO!

‘Serial Number "oo .

‘Dela Loggerfirmware 26.1

D0 Meter Test

Cdeneterieee

[wentiradvave

49en

Shem

Page Lot?

Calliper Sensor Test simulation result

Caliper sensor tested with ppiying height of precefined value in mm using verneer tool tor

Getlecticn on each sensor atry Outfiut of eech sensar arm of calliper toal using PET utility

software recorded and reported in below g ver table

TT

"so! | NeghtActlied Revortec (im)

Position

rr en] ax tL HCL

oo PREPARED BY REVIEWED BY WATNESSED BY | WATNESSED BY

TARE Vetal Patel

“DESIGNATION | Onerations Manager

‘DRE

SENATURT

LL

Page 2of2

pipslines2data

Note Al of the folowing epecitcations ave eta ‘00! gpacieattons ent ba wehanced and

iliore to nveat clon! roqulrarierts ar

rt P2D components

‘pone demands

mam nore cn

1183, agh 20% Bare Ping

| ineine anvrorment qu, Gas, Mutienass

[ Nami tener can [pie a

| coming Peee 0.00 Bar,

oon re gina

osc

[ove

oneters 2 |wa Jers eeremanosianse, | \onm

ole Depenge af un euaaon ate mole eee

IncLaee ae Fou

Peon i Data 3¥o ma, Mons Comme ar, Aber. AEE: Ak

Pe Ae(1224 708778 Fae LAIO77C TONSA wee ltneszbaead

ron

i ELECTRONIC GEOMETRIC TOOL

LO | Weight after a ike

ZO) Namber o” Modules oPtonteand length of rol Slgle Medale, = 32

"Principle of operation. 7 | Hall eee:

40° | Capebilty of inepectiag Manitzum leagth insinge | 150 Kme

Ln. ee ==

O Pressure age

Temperate range Tere

Bevery hte OO

EO Tayi deicating P9h dem VESNO

Accunacy fi denth sizing for aeat ae ~~

| toa” Sbeed rape fr daa pene i ms

180 | Numnbero! sensors - 16 Ruinders

120 | Frequency er distance of sampling 1009 sanvples

ra

pebility te tdentify Following as = minimum

|

Bu Incividual girth weld YES

po —

132 | Dentend Ovaliy YES

133) QuteP roundness is

na ves of any partially closea valve YES

40 | Minirium % of TD thet the EGP pig pass without 254 oF |

Ing pig and pipe

50" Apal&i Circumferential accuiacy of locating defect 1% Rom Nearest Feature

fom seference riackesfo peline feative | lo Degee

60 | “Aociracy 9F meesiroment for depth of avality rere)

‘7D | Bend radius the too! able tn newntiate | wD a

#0 Schersatie suetch encloacd indivalng sonhiguaton | Ves (Annexe 1)

[TOD | Any ater real specific ifiernetion

2.0 PROFORMA FUR MAGNET CLEANING & ES

FORM A PROFORMA FOR MAGNET CL FANING MiG DETAILS DIAMETER OF

at

ahhh nl

MAGNET BOX,

stato

cD 19¢

FORN B PROFORMA FOS ELECTRONIC GEOMETRY PIG QE TAILS SIAME TER OF

EGP

TT oe oe

eNO] Description Pudiles detats a1 YesNO

1 26 kgs -

{2 lumber ales. ander tn 1 Nos. & Lengih 1370 mire

a RR ccs

[G0 Bapaniivatinapasing Maxmurtengminange TORTS

[oe Tabet

oo ange conngurston

eae = aR

feo [Tewpe OF ieee

70 Gi

[Po [Canabiny ofteecne dee SiS

2.0 Roounaey fer decth sane for cent _ Tie a ee OD

100 ‘Speed range for data generation howe

[ito [hurberofsensos SSCSS*«*i ~

[ooo

ZO, Frequency or distance of samolin

free iseniy by olow"g aba ninirurh

mt ith weld YES

[ee [ont ena vty ves

[33 Gutatemoness Te

Vavesoreryparisiycosedvave ES

co Minirum% of Dthalthe GR gignasswathout PO

camacivo na endnne

760 Arial Croumierertia, acwurasy of locating Atal 70mm, 4

celect rem releresce markerfppelivateature —crcurveren:

[160 [Accuracy of measurement‘ordestctovay Pe

$70 Band eahie he too! able io nayatiate

| Schematic sketch encloee? incieatng configuraion Arnenaire 4

| Ary othor fool specie -fermation (2 Odametic asseriaiy?

distance meas."ement

CORRTECH |

UPROIECT |: PALANPUR VADODARA PIPE LINE PROJECT FARI-4.. (PYPL) |

CLIENT M/s: - HINDUSTAN PETROLEUM CORPORATION LIMITED, - (HECL) |

(CONSULTANT: M/s:- ENGINEERS INDIA LTE. -{EIL)

| CONTRACTOR |: M/s: CORRTECH INTERNATIONAL PVT.LTL )

JOB NOQ.: A848

_ __ a |

' JOB PROCEDURE FOR

BENTONITE FILLING

| PROCEDURE No.: HPCL/EIL/CIPL/PVPL/ML/JP-29

Pt

ENGINEERS INDIA LTD. (EiL)

ifs +- CORRTECH INTERNATIONAL PVT.LTD. - {CIPL]

LOL NO ; 17000045-0Q-10129 DATED : 04.08.2017

JOB NO: A848

JOB PROCEDURE FOR

BENTONITE FILLING

DOCUMENT NO: HPCL/EIL/CIPL/PVPL/ML/JP-29

[os -as0n38—

JOB PROCEDURE FOR BENTOWITE FILLING |

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Sop-11 HDDDocument15 pagesSop-11 HDDVineet AgrawalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- Job Safety AnalysisDocument19 pagesJob Safety AnalysisVineet Agrawal100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- R1937-JSA-003 Job Safety Analysis For TrenchingDocument5 pagesR1937-JSA-003 Job Safety Analysis For TrenchingVineet AgrawalNo ratings yet

- HIRA For Laying of PipelineDocument33 pagesHIRA For Laying of PipelineVineet Agrawal100% (4)

- SOP-9 - OFC Laying ActivitiesDocument12 pagesSOP-9 - OFC Laying ActivitiesVineet AgrawalNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- R1937-JSA-002 Job Safety Analysis For TowingDocument4 pagesR1937-JSA-002 Job Safety Analysis For TowingVineet AgrawalNo ratings yet

- Method Statement of Pipeline Pigging Services: Polmaz LimitedDocument10 pagesMethod Statement of Pipeline Pigging Services: Polmaz LimitedVineet Agrawal100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- SOP-10 Pre Commissioning and Commissioning ActivitiesDocument14 pagesSOP-10 Pre Commissioning and Commissioning ActivitiesVineet AgrawalNo ratings yet

- 30 BrocherDocument4 pages30 BrocherVineet AgrawalNo ratings yet

- Special Terms and Conditions of Contract For Supply of Manpower Services On Conctractual Basis For A Fixed PeriodDocument12 pagesSpecial Terms and Conditions of Contract For Supply of Manpower Services On Conctractual Basis For A Fixed PeriodVineet AgrawalNo ratings yet

- Revision and Amendment Sheet: Safety Procedure For HydrotestingDocument8 pagesRevision and Amendment Sheet: Safety Procedure For HydrotestingVineet AgrawalNo ratings yet

- SOP-8 Installation of Various MarkersDocument11 pagesSOP-8 Installation of Various MarkersVineet AgrawalNo ratings yet

- SOP-10 Bored Cased CrossingsDocument14 pagesSOP-10 Bored Cased CrossingsVineet AgrawalNo ratings yet

- Corrosive - CleanupDocument4 pagesCorrosive - CleanupVineet AgrawalNo ratings yet

- Job Safety Analysis For Internal Corrosion Monitoring PDFDocument2 pagesJob Safety Analysis For Internal Corrosion Monitoring PDFVineet AgrawalNo ratings yet

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocument3 pagesR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNo ratings yet

- SOP-9 - Tie in JointsDocument18 pagesSOP-9 - Tie in JointsVineet AgrawalNo ratings yet

- 01 522991Document162 pages01 522991Vineet AgrawalNo ratings yet

- R1937-JSA-002 Job Safety Analysis For TowingDocument4 pagesR1937-JSA-002 Job Safety Analysis For TowingVineet Agrawal100% (1)

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet AgrawalNo ratings yet

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet Agrawal100% (1)

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocument3 pagesR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNo ratings yet

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- Revision and Amendment Sheet: Safety Procedure For Survey ActivitiesDocument10 pagesRevision and Amendment Sheet: Safety Procedure For Survey ActivitiesVineet AgrawalNo ratings yet