Hydraulic elevator system - ALGI

Hydraulic elevator system - ALGI

Hydraulic elevator system - ALGI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HYDRAULIC SYSTEMS • LIFT COMPONENTS<br />

<strong>Hydraulic</strong> <strong>elevator</strong> <strong>system</strong><br />

Solutions in accordance with EN 81 – 2 A3<br />

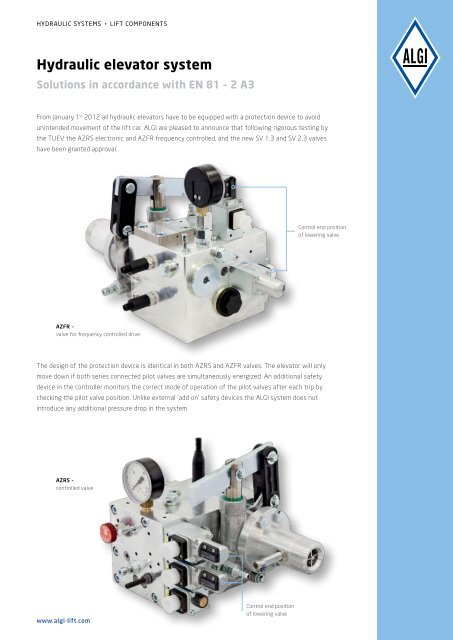

From January 1 st 2012 all hydraulic <strong>elevator</strong>s have to be equipped with a protection device to avoid<br />

C: 99 %<br />

M: 77 %<br />

Y: 0 %<br />

K: 0 %<br />

C: 44 %<br />

M: 13 %<br />

Y: 0 %<br />

K: 0 %<br />

C: 0 %<br />

M: 0 %<br />

Y: 0 %<br />

K: 100 %<br />

unintended movement of the lift car. <strong>ALGI</strong> are pleased to announce that following rigorous testing by<br />

the TUEV the AZRS electronic and AZFR frequency controlled, and the new SV 1.3 and SV 2.3 valves<br />

have been granted approval.<br />

Control end position<br />

of lowering valve<br />

AZFR –<br />

valve for frequency controlled drive<br />

The design of the protection device is identical in both AZRS and AZFR valves. The <strong>elevator</strong> will only<br />

move down if both series connected pilot valves are simultaneously energized. An additional safety<br />

device in the controller monitors the correct mode of operation of the pilot valves after each trip by<br />

checking the pilot valve position. Unlike external ‘add on’ safety devices the <strong>ALGI</strong> <strong>system</strong> does not<br />

introduce any additional pressure drop in the <strong>system</strong>.<br />

AZRS –<br />

controlled valve<br />

www.algi-lift.com<br />

Control end position<br />

of lowering valve

HYDRAULIC SYSTEMS • LIFT COMPONENTS<br />

Block Valve SV<br />

Size 1.3 and 2.3<br />

C: 99 %<br />

M: 77 %<br />

Y: 0 %<br />

K: 0 %<br />

C: 44 %<br />

M: 13 %<br />

Y: 0 %<br />

K: 0 %<br />

C: 0 %<br />

M: 0 %<br />

Y: 0 %<br />

K: 100 %<br />

The proven mechanical AZSTB valves do not<br />

have the option of the additional pilot valve.<br />

For these applications <strong>ALGI</strong> have developed the<br />

SV 1.3 and 2.3 safety valves. The safety valve<br />

only allows oil flow from the lift jack to the<br />

power unit if the pilot valve is energised.<br />

Block valve SV<br />

As soon as the voltage is removed from the pilot<br />

valve further downward movement is prevented.<br />

In the up direction oil flow is allowed with the<br />

pilot valve de-energised.<br />

Valve S5<br />

Available valve voltages:<br />

12V DC, 24V DC, 42V DC, 48V DC, 80V DC,<br />

110V DC, 185V DC, 230V AC<br />

Type 1.3 flow rate up to 500 l per min<br />

Type 2.3 flow rate up to 800 l per min<br />

Direct add-on to AZSTB, AZRS and AZFR<br />

Temperature range from 10 - 60°C<br />

Pressure range from 15 to 64 bar<br />

Pressure switch<br />

Installation at the lift jack<br />

The valve has also been designed for direct<br />

installation to the lift jack. We would advise<br />

wherever possible that this is the preferred<br />

installation point as it will also protect against<br />

hose failure. When installed in this position the<br />

manual lowering and pressure control is achieved<br />

by an additional assembly at the power unit.<br />

www.algi-lift.com