SELECTING pumps - Sauermann

SELECTING pumps - Sauermann

SELECTING pumps - Sauermann

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The installation<br />

GUIDE<br />

www.sauermann<strong>pumps</strong>.com<br />

®<br />

FOLLOW<br />

The installation GUIDE

CONTENTS<br />

GENERAL INFORMATION<br />

Why, how? p. 4<br />

2 evacuation options<br />

What is a condensate removal pump? p. 5<br />

Advantages<br />

Different types: piston, impeller<br />

and peristaltic<br />

Which operating mode? p. 6<br />

3 different ways<br />

Which detection system? p. 6 - 7<br />

3 detection systems<br />

HOW TO CHOOSE YOUR<br />

CONDENSATE REMOVAL<br />

PUMP<br />

Which pump for which system? p. 8<br />

Removal pump tables<br />

Cooling capacity p. 12<br />

Actual flow rates p. 13<br />

Technical specifications<br />

of the <strong>pumps</strong> p. 21<br />

HOW TO INSTALL YOUR<br />

CONDENSATE REMOVAL PUMP<br />

A few basic rules p. 22<br />

DELTA PACK, pump with integral detection p. 24<br />

Piston <strong>pumps</strong> with remote detection p. 26<br />

Monoblock impeller <strong>pumps</strong> with tank p. 29<br />

Peristaltic <strong>pumps</strong> p. 32<br />

Dosing pump p. 36<br />

Wiring diagrams p. 37<br />

Alarm operating examples p. 40<br />

ACCESSORIES:<br />

ESSENTIALS P. 42<br />

QUALITY, GUARANTEE,<br />

SERVICE P. 44<br />

NOTES p. 46<br />

This guide has been produced with the generous<br />

support of Messrs. Maurice Perez, Paul Henri Blanc<br />

and Jean-Pierre Benoist.

GENERAL INFORMATION<br />

WHAT IS a condensate<br />

removal pump?<br />

WHY, how?<br />

Condensates (drops of water caused by warm, humid air passing over a cold<br />

surface) are formed in air conditioning, refrigeration and condensing boiler<br />

units.<br />

There are 2 ways of removing them<br />

It is a system which consists of a pump unit and a detection unit allowing<br />

condensates to be evacuated to a water drainage outlet where there is no<br />

gravity fall.<br />

This technology has 3 advantages:<br />

❶ It protects the appearance of the customer’s installation (no<br />

unsightly pipework).<br />

Gravity evacuation<br />

Evacuate the condensates<br />

by gravity, which means<br />

dealing with technical and<br />

aesthetic problems (distant<br />

drainage outlet, not enough<br />

fall, damage to walls and<br />

unsightly pipework).<br />

The removal pump<br />

1 2<br />

Or, install a condensate<br />

removal pump (smaller<br />

dimensions, the<br />

appearance of the<br />

installation is preserved,<br />

simple and quick to<br />

install, safer as equipped<br />

with alarm and<br />

non return valve).<br />

❷ Easy, simple and safe to install.<br />

❸ Reduction of the risk of bacterial contamination by waste water<br />

(no stagnation or back-flow of water due to non return valves)<br />

There are 3 types of condensate removal <strong>pumps</strong>:<br />

PISTON<br />

IMPELLER<br />

PERISTALTIC<br />

Air<br />

conditioning<br />

Refrigeration<br />

Heating<br />

4<br />

General information<br />

5<br />

General information

WHICH operating mode?<br />

Whether monoblock or compound type, condensate removal <strong>pumps</strong><br />

operate in 3 different ways:<br />

The second<br />

is based on a float switch controlling 3 levels:<br />

❶ Reciprocating piston method<br />

These <strong>pumps</strong> are fitted with a piston which first draws in, then evacuates the<br />

condensate.<br />

❷ Centrifugal impeller method<br />

A centrifugal impeller evacuates the condensate. These <strong>pumps</strong> are intended<br />

for high flow rate requirements and are particularly suitable for contaminated<br />

condensates<br />

3<br />

1<br />

2<br />

1. On,<br />

2. Off,<br />

3. Alarm.<br />

➜ Fitted on piston <strong>pumps</strong>.<br />

❸ Peristaltic <strong>pumps</strong><br />

A roller compresses a pipe which drives out the condensates (containing<br />

contaminates or not). These <strong>pumps</strong> are self-priming and can operate dry.<br />

WHICH detection system?<br />

SAUERMANN has developed<br />

3 detection systems:<br />

The first is based on two mechanical float switches<br />

one of which controls the On/Off levels and the<br />

other the Alarm.<br />

➜ Fitted on impeller <strong>pumps</strong>.<br />

As it is largely unaffected by the nature of the condensates (oil or grease on<br />

the surface, deposits of scale, dust or algae formation) float switch detection<br />

is very reliable.<br />

The presence of an alarm level leads to increased safety.<br />

As soon as a problem is detected (abnormally high water level leading to a<br />

risk of overflow), the pump automatically cuts off the air conditioning<br />

system compressor or triggers an audible or visual alarm.<br />

Problems may be caused by different reasons:<br />

- power cut<br />

- pump stoppage<br />

- pinched pipe<br />

3<br />

The third operates by detecting a temperature difference across the cooling<br />

coil of more than 6°C between two temperature sensors.<br />

➜ Fitted on PE 5100 peristaltic <strong>pumps</strong>.<br />

On/OfF<br />

Alarm<br />

6<br />

General information<br />

7<br />

General information

HOW TO CHOOSE YOUR<br />

CONDENSATE REMOVAL PUMP<br />

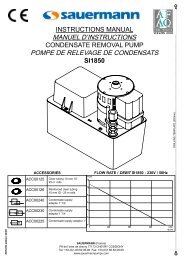

<strong>SELECTING</strong> <strong>pumps</strong><br />

Piston <strong>pumps</strong> for air conditioners up to 10 kW and up to 30 kW<br />

WHICH PUMP FOR WHICH SYSTEM?<br />

Multi<br />

Cassette<br />

systems<br />

Air conditioning<br />

units<br />

Wall-mounted<br />

air conditioners<br />

Ceiling suspended<br />

DX / Chilled water<br />

fan-coil units consoles<br />

Ducted<br />

YOU NEED TO KNOW<br />

THE FOLLOWING<br />

CHARACTERISTICS:<br />

❶ The volume of condensates<br />

produced or the refrigerating<br />

capacity of your installation<br />

will give you an indication<br />

of the volume of condensates<br />

to be removed.<br />

❷ The type of appliance<br />

which you are fitting it to.<br />

Choose your pump based<br />

on these characteristics.<br />

Check that the model<br />

you choose has<br />

a sufficient flow rate /<br />

pressure ratio.<br />

APPLICATIONS<br />

AIR CONDITIONING<br />

Max cooling capacity<br />

WALL OR FLOOR<br />

MOUNTED<br />

Wall<br />

Consoles<br />

Fan-coil units<br />

Air conditioning<br />

units<br />

CEILING<br />

MOUNTED<br />

Ceiling suspended<br />

Ducted units<br />

Cassette or<br />

multi cassette systems<br />

SI 1082<br />

DELTA PACK<br />

D: 8 l/h<br />

R: 6 m<br />

SI 3080<br />

D: 8 l/h<br />

A: 1 m<br />

R: 6 m<br />

SI 3100<br />

SI 2750<br />

D: 10 l/h<br />

A: 2 m<br />

R: 6 m<br />

SI 3200<br />

D: 20 l/h<br />

A: 2 m<br />

R: 6 m<br />

SI 1730<br />

D: 30 l/h<br />

A: 2,50 m<br />

R: 10 m<br />

EE 1650<br />

D: 30 l/h<br />

R: 13 m<br />

10 kW 10 kW 10 kW 20 kW 30 kW 30 kW<br />

D: Flow rate - A: Suction - R: Discharge<br />

8<br />

Selection - <strong>pumps</strong><br />

9<br />

Selection - <strong>pumps</strong>

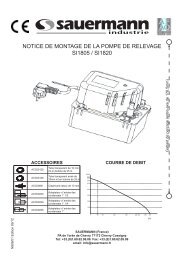

<strong>SELECTING</strong> <strong>pumps</strong><br />

Centrifugal impeller method<br />

Multi Cassette<br />

systems<br />

Peristaltic <strong>pumps</strong><br />

Air conditioning<br />

units<br />

Wall-mounted<br />

air conditioners<br />

WHICH PUMP FOR WHICH SYSTEM?<br />

Ceiling suspended<br />

DX / Chilled water<br />

fan-coil units<br />

Ducted<br />

Refrigerated<br />

display<br />

cabinets<br />

Condensing<br />

boilers<br />

APPLICATIONS<br />

SI 1800 SI 1805 - SI 1820 SI 1822 SI 1850 PE 5000 - PE 5100 - PE 5200 PE 6250 PE 6000<br />

D: 300 l/h<br />

D: 500 l/h<br />

D: 380 l/h<br />

D: 1100 l/h<br />

R: 4,70 m<br />

R: 5,40 m<br />

R: 6,20 m<br />

R: 11 m<br />

D: 6 l/h<br />

A: 2 m<br />

R: 12 m<br />

D: 25 l/h<br />

A: 2 m<br />

R: 10 m<br />

D: 1,5 l/h<br />

A: 2 m<br />

R: 15 m<br />

AIR CONDITIONING<br />

Max cooling capacity<br />

WALL OR FLOOR<br />

MOUNTED<br />

Wall<br />

Consoles<br />

Fan-coil units<br />

Air conditioning<br />

units<br />

CEILING<br />

MOUNTED<br />

Ceiling suspended<br />

Ducted units<br />

Cassette or multi<br />

cassette systems<br />

REFRIGERATION<br />

Evaporators<br />

Display cabinets<br />

Humidifiers/<br />

dehumidifiers<br />

HEATING<br />

Gas condensing boilers<br />

AIR COOLING<br />

TOWERS<br />

D: Flow rate - A: Suction - R: Discharge<br />

8 kW<br />

10<br />

Selection - <strong>pumps</strong><br />

Please contact us should you require<br />

any assistance in selecting a pump.<br />

11<br />

Selection - <strong>pumps</strong>

Cooling capacity and<br />

examples of actual flow rates<br />

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA SI PACK 1082 -<br />

THE REFRIGERATING CAPACITY GIVES YOU<br />

THE VOLUME OF CONDENSATES TO BE REMOVED<br />

THE HEAD LOSSES DEFINED IN THIS<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

FLEXIBLE PIPEWORK OF 6 MM<br />

DISCHARGE<br />

HEAD<br />

TOTAL PIPE LENGTH<br />

5 m 10 m 20 m 30 m<br />

Use the cooling capacity information supplied by the manufacturer of the air<br />

conditioner. It is generally estimated that, for normal usage conditions, the<br />

volume of condensates to be removed varies from 0.5 to 0.8 l/hr per kW of<br />

cooling capacity. This value may be doubled in very humid areas.<br />

For example: a cooling capacity of 3 kW will produce<br />

from 1.5 to 2.4 l/hr of condensates to be removed.<br />

INTERNAL DIAMETER<br />

1 m 6.8 6.3 5.3 4.3<br />

2 m 5.5 5 4.1 3.2<br />

3 m 4.2 3.8 3 2.5<br />

4 m 3 2.6 2.2 2<br />

5 m 2.2 2 1.8 1.5<br />

6 m 1.5 1.4 1.2 1<br />

Installation Overview<br />

Pour les pompes SI 1082, , SI 3080, SI 3100, SI 3200, SI 2750, SI 1730,<br />

PE 5000, PE 5100, PE 5200, PE 6250<br />

You must<br />

take into<br />

account the<br />

head loss<br />

connected<br />

with:<br />

The suction head if the pump<br />

is installed higher than the air<br />

conditioner.<br />

The discharge head<br />

The total length of the pipe<br />

Pump<br />

ACC 00205<br />

SI 1082 / DELTA PACKSI 3080<br />

THE HEAD LOSSES DEFINED IN THIS<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

DISCHARGE<br />

HEAD<br />

TOTAL PIPE LENGTH<br />

FLEXIBLE PIPEWORK OF 6 MM<br />

5 m 10 m 20 m 30 m<br />

INTERNAL DIAMETER<br />

1 m 6.8 6.3 5.3 4.3<br />

SUCTION 2 m 5.5 5 4.1 3.2<br />

HEAD 3 m 4.2 3.8 3 2.5<br />

0 m 4 m 3 2.6 2.2 2<br />

5 m 2.2 2 1.8 1.5<br />

6 m 1.5 1.4 1.2<br />

Pump<br />

SI 1082<br />

ACC 00209<br />

Detection<br />

Connections are always made above the level of the pump to prevent a<br />

siphon effect in the pipes and the pump becoming unprimed (B>0).<br />

NOTE: If the discharge connection is made below the level of the pump<br />

then fit the <strong>Sauermann</strong> anti-siphon device ACC00214.<br />

1 m 5.6 5.2 4.3 3.4<br />

MAX 2 m 4.3 3.9 3.1 2.3<br />

SUCTION HEAD 3 m 3 2.7 2 1.6<br />

1 m 4 m 1.8 1.5 1.2 1.1<br />

5 m 1 0.9 0.8 0.6<br />

6 m 0.3 0.2 0.2 0.1<br />

12<br />

Selection - power<br />

13<br />

Selection - flow rates

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA SI PACK 3100 - SI 2750<br />

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA PACKSI 3200<br />

THE HEAD LOSSES DEFINED<br />

DISCHARGE<br />

THE HEAD LOSSES DEFINED<br />

DISCHARGE<br />

IN THIS TABLE ARE CALCULATED HEAD TOTAL PIPE LENGTH<br />

WITH 1/4’’ FLEXIBLE PIPEWORK 5 m 10 m 20 m 30 m<br />

OF 6 MM INTERNAL DIAMETER<br />

IN THIS TABLE ARE CALCULATED HEAD TOTAL PIPE LENGTH<br />

WITH 1/4’’ FLEXIBLE PIPEWORK OF 5 m 10 m 20 m 30 m<br />

6 MM INTERNAL DIAMETER<br />

1 m 9.5 9 8.2 7.4<br />

SUCTION 2 m 7 6.5 5.7 4.9<br />

HEAD 3 m 5 4.6 3.9 3.4<br />

0 m 4 m 4 3.6 3.1 2.8<br />

5 m 3.2 2.7 2.5 2.3<br />

6 m 2.5 2.2 2 1.8<br />

1 m 19 17.5 15.5 13.5<br />

SUCTION 2 m 17.5 16 14 12<br />

HEAD 3 m 16 14 12 10<br />

0 m 4 m 14 12 10 8.5<br />

5 m 11.5 10 8.5 7<br />

6 m 9.5 8 7 6<br />

1 m 7.5 7 6.2 5.4<br />

MAX 2 m 6 5 4.2 3.4<br />

SUCTION HEAD 3 m 4.8 3.5 2.9 2.5<br />

1 m 4 m 3.6 2.6 2.1 1.8<br />

5 m 2.2 1.7 1.5 1.3<br />

6 m 1.5 1.2 1 0.8<br />

1 m 16.5 15.5 13.5 12<br />

SUCTION 2 m 14.5 13.5 11.5 11<br />

HEAD 3 m 12.5 11.5 10.5 10<br />

1 m 4 m 10 9 8.5 8<br />

5 m 8.5 7.5 6.5 5.5<br />

6 m 7 5 4 3<br />

1 m 6.2 5.7 4.9 4.1<br />

MAX 2 m 5 4.5 3.7 2.9<br />

SUCTION HEAD 3 m 3.8 3.4 2.7 2.2<br />

2m 4 m 2.4 2 1.5 1.2<br />

5 m 1 0.5 0.3 0<br />

6 m 0.5 0 0 0<br />

1 m 13 12.5 12 11<br />

MAX 2 m 12 11.5 11 10<br />

SUCTION HEAD 3 m 11 10.5 10 9<br />

2 m 4 m 8 7.5 7 6<br />

5 m 6 5.5 5 5<br />

6 m 4 3.5 3 3<br />

14<br />

Selection - flow rates<br />

15<br />

Selection - flow rates

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA PACKSI 1730<br />

Installation overview<br />

For <strong>pumps</strong> EE1650, SI1800, SI1805, SI1820, SI1822, SI1850<br />

THE HEAD LOSSES DEFINED<br />

DISCHARGE<br />

IN THIS TABLE ARE CALCULATED HEAD TOTAL PIPE LENGTH<br />

WITH 1/4’’ FLEXIBLE PIPEWORK OF 5 m 10 m 20 m 30 m<br />

6 MM INTERNAL DIAMETER<br />

1 m 29 27 25 23<br />

SUCTION 2 m 27.5 25.5 24 22<br />

HEAD 3 m 25.5 24 22 20.5<br />

0 m 4 m 23.5 22 20 19<br />

5 m 21 19.5 18 16.5<br />

6 m 18 16.5 15 14<br />

7 m 15.5 14 12.5 11.5<br />

8 m 13 11.5 10 9<br />

9 m 10.5 9 7.5 6.5<br />

10 m 7.5 6 5 4<br />

1 m 24 22 20 20<br />

SUCTION 2 m 22 21 20 19<br />

HEAD 3 m 20 19 18 17.5<br />

1 m 4 m 17 16.5 16 15.5<br />

5 m 14.5 14 13.5 13.5<br />

6 m 12 11.5 11 11<br />

7 m 10.5 10 9.5 9<br />

8 m 8.5 8 7.5 7<br />

9 m 6.5 6 5.5 5<br />

10 m 5 4 3.5 3<br />

1 m 20 19 18 17.5<br />

MAX 2 m 17 16.5 16 15.5<br />

SUCTION HEAD 3 m 14.5 14 13.5 13.5<br />

2 m 4 m 12 11.5 11 11<br />

5 m 10.5 10 9.5 9<br />

6 m 8.5 8 7.5 7<br />

7 m 6.5 6 5.5 5<br />

8 m 5 4 3.5 3<br />

9 m 2.5 2 1.5 1<br />

PUMP<br />

PUMP<br />

or<br />

Discharge head<br />

Total pipe length<br />

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA PACKEE 1650<br />

THE HEAD LOSSES DEFINED IN THIS DISCHARGE<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

HEAD<br />

TOTAL PIPE LENGTH<br />

FLEXIBLE PIPEWORK OF 6 MM INTER-<br />

5 m 10 m 20 m 30 m<br />

NAL DIAMETER<br />

1 m 29 27 25 23<br />

2 m 27.5 25.5 24 22<br />

3 m 25.5 24 22 20.5<br />

4 m 23.5 22 20 19<br />

5 m 21 19.5 18 16.5<br />

6 m 18 16.5 15 14<br />

7 m 15.5 14 12.5 11.5<br />

8 m 13 11.5 10 9<br />

9 m 10.5 9 7.5 6.5<br />

10 m 7.5 6 5 4<br />

16<br />

Selection - flow rates<br />

17<br />

Selection - flow rates

Actual flow rates for the <strong>pumps</strong><br />

SI 1082 / DELTA PACKSI 1800<br />

SI 1082 / DELTA PACKSI 1822<br />

THE HEAD LOSSES DEFINED<br />

IN THIS<br />

DISCHARGE<br />

TOTAL PIPE LENGTH<br />

THE HEAD LOSSES DEFINED<br />

IN THIS<br />

DISCHARGE<br />

TOTAL PIPE LENGTH<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

HEAD 5 m 10 m 20 m 30 m<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

HEAD 5 m 10 m 20 m 30 m<br />

FLEXIBLE PIPEWORK OF 10 MM<br />

(IN L/H) (IN L/H) (IN L/H) (IN L/H)<br />

FLEXIBLE PIPEWORK OF 10 MM<br />

(IN L/H) (IN L/H) (IN L/H) (IN L/H)<br />

INTERNAL DIAMETER<br />

INTERNAL DIAMETER<br />

1 m 230 180 145 120<br />

1 m 330 260 220 190<br />

2 m 165 130 100 85<br />

2 m 275 220 190 160<br />

3 m 100 80 60 50<br />

3 m 220 175 155 135<br />

4 m 40 30 20 15<br />

4 m 160 130 120 100<br />

5 m 100 80 70 60<br />

6 m 20 15 10 10<br />

SI 1082 / DELTA PACKSI 1850<br />

SI 1082 / DELTA SI PACK 1805 - SI 1820<br />

THE HEAD LOSSES DEFINED IN THIS<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

FLEXIBLE PIPEWORK OF 10 MM<br />

INTERNAL DIAMETER<br />

DISCHARGE<br />

TOTAL PIPE LENGTH<br />

HEAD 5 m 10 m 20 m 30 m<br />

(IN L/H) (IN L/H) (IN L/H) (IN L/H)<br />

1 m 460 380 280 200<br />

2 m 390 320 240 180<br />

3 m 300 250 190 150<br />

4 m 200 180 130 100<br />

5 m 90 80 60 50<br />

THE HEAD LOSSES DEFINED IN THIS<br />

TABLE ARE CALCULATED WITH 1/4’’<br />

FLEXIBLE PIPEWORK OF 10 MM<br />

INTERNAL DIAMETER<br />

DISCHARGE<br />

TOTAL PIPE LENGTH<br />

HEAD 5 m 10 m 20 m 30 m<br />

(IN L/H) (IN L/H) (IN L/H) (IN L/H)<br />

1 m 750 590 375 285<br />

2 m 675 545 345 270<br />

3 m 600 500 310 255<br />

4 m 520 460 285 235<br />

5 m 450 410 255 215<br />

6 m 355 225 190<br />

7 m 300 185 160<br />

8 m 240 145 125<br />

9 m 170 100 85<br />

10 m 85 60 45<br />

18<br />

Selection - flow rates<br />

19<br />

Selection - flow rates

Actual flow rates for the <strong>pumps</strong><br />

Technical specifications<br />

SI 1082 / PE DELTA 5000 PACK - PE 5100 - PE 5200<br />

Flow rate 6 I/h Max suction head 2 m Max vertical discharge 12 m<br />

Pumps<br />

DETECTION LEVELS<br />

+/- 2mm<br />

On Off Alarm<br />

Sound<br />

level<br />

Alarm contact at<br />

250V<br />

DIMENSIONS<br />

l x w x h in mm<br />

Pump<br />

unit<br />

Detection<br />

unit<br />

SI 1082 / DELTA PACKPE 6000<br />

Flow rate 1,5 I/h Max suction head 2 m Max vertical discharge 15 m<br />

SI 1082<br />

SI 2750<br />

SI 3080<br />

SI 3100<br />

18 12 21<br />

16 11 19<br />

21,5 dB(A)<br />

32 dB(A)<br />

20,2 dB(A)<br />

25,1 dB(A)<br />

NC<br />

NO/NC<br />

NC<br />

NC<br />

8 A resistive<br />

8 A resistive<br />

8 A resistive<br />

8 A resistive<br />

66 x 44 x 77<br />

61 x 38 x 76<br />

66 x 44 x 59<br />

66 x 44 x 59<br />

55 x 38 x 36<br />

55 x 38 x 36<br />

55 x 38 x 36<br />

SI 1082 / DELTA PACKPE 6250<br />

Flow rate 25 I/h Max suction head 2 m Max vertical discharge 10 m<br />

SI 3200<br />

SI 1730<br />

17 11 21<br />

32,4 dB(A)<br />

42 dB(A)<br />

NC<br />

NO/NC<br />

8 A resistive<br />

8 A resistive<br />

66 x 44 x 59<br />

74 x 52 x 95<br />

55 x 38 x 36<br />

55 x 38 x 36<br />

PE 5000<br />

30 dB(A)<br />

109 x 110 x 91<br />

PE 5100<br />

30 dB(A)<br />

NC<br />

8 A resistive<br />

109 x 110 x 91<br />

PE 5200<br />

16 11 19<br />

30 dB(A)<br />

109 x 110 x 91<br />

55 x 38 x 36<br />

MONOBLOCK PUMPS WITH TANK<br />

Pumps<br />

On Off Alarm<br />

Sound<br />

level<br />

Alarm contact at<br />

250V<br />

Pump<br />

unit<br />

Detection<br />

unit<br />

EE 1650<br />

Under the tank 16 10 21 52 dB(A) NC 8 A resistive 160 x 85 x 88<br />

0,5 l<br />

In the tank 21 15 26 52 dB(A) NC 8 A resistive 160 x 85 x 88<br />

0,5 l<br />

SI 1800<br />

40<br />

28<br />

66<br />

54 dB(A)<br />

NC<br />

4 A resistive<br />

283 x 127 x 161<br />

2 l<br />

SI 1805<br />

24<br />

13<br />

30<br />

47 dB(A)<br />

NC<br />

4 A resistive<br />

195 x 130 x 122<br />

0,5 l<br />

SI 1820<br />

43<br />

27<br />

67<br />

47 dB(A)<br />

NC<br />

4 A resistive<br />

195 x 130 x 170<br />

2 l<br />

SI 1822<br />

75<br />

20<br />

90<br />

47 dB(A)<br />

NC<br />

4 A resistive<br />

305 x 152 x 235<br />

3,8 l<br />

SI 1850<br />

70<br />

20<br />

95<br />

66 dB(A)<br />

NC<br />

4 A resistive<br />

305 x 152 x 257<br />

3,8 l<br />

20<br />

Selection - flow rates<br />

21<br />

Selection – detection levels

HOW TO INSTALL YOUR<br />

CONDENSATE REMOVAL PUMP<br />

A few Basic Rules<br />

IMPORTANT NOTE ON<br />

COMMISSIONING PUMPS<br />

WITH REMOTE DETECTION<br />

Before installation, thoroughly rinse the coil<br />

and the condensates collection tank to<br />

remove any foreign bodies and metal<br />

particles.<br />

When the pump has a separate detection<br />

unit, it must be fixed horizontally on a<br />

support.<br />

Monoblock tank <strong>pumps</strong> must always be fitted<br />

horizontally on a support.<br />

Before carrying out<br />

any operation on<br />

the pump, make<br />

sure the installation<br />

is disconnected from<br />

the power supply.<br />

To ensure that the <strong>pumps</strong> function correctly in<br />

the future, ensure that when you first commission<br />

them (and after each maintenance operation)<br />

the <strong>pumps</strong> are properly primed.<br />

Check that the suction pipe (between the<br />

detection unit and the pump) and part of the<br />

discharge pipe are filled with water.<br />

Failure to observe these rules can lead to poor results (tank overflow, high<br />

noise level, abnormal overheating etc.) which are both inconvenient for the<br />

end user and costly for the installer.<br />

You can use the priming squeezie<br />

bottle ACC 00401.<br />

YOU ARE STRONGLY ADVISED TO AVOID THE USE OF DETERGENT OR AGGRES-<br />

SIVE PRODUCTS WHEN CLEANING THE TANK OF MONOBLOCK PUMPS<br />

22<br />

Installation - rules<br />

23<br />

Installation - rules

Piston pump with integral detection<br />

Piston pump with integral detection<br />

Ready to fit assembly for wall-mounted air<br />

conditioners up to 10 kW<br />

READY TO FIT<br />

Delta Pack comprises:<br />

- a mini pump with integral detection SI 1082<br />

- a complete assembly kit containing:<br />

• a clip-on cover,<br />

• 75 cm of 80 x 60 mm duct,<br />

• all assembly accessories.<br />

AIR<br />

CONDITIONING<br />

REVERSIBLE LEFT OR<br />

RIGHT ASSEMBLY<br />

Installation template<br />

supplied<br />

INSTRUCTIONS INSTALLATION SI 1082<br />

Allows the pump to be assembled on the left or right of the air conditioner.<br />

Reversible anti-vibration<br />

PRACTICAL CLIP-ON<br />

COMPONENTS<br />

Support antivibratoir<br />

réversible<br />

Simple electrical connection<br />

Raccordement électronique<br />

simplifié<br />

LARGE AREA<br />

FOR<br />

COOLING PIPES<br />

support<br />

Clip-on pipe, elbow and ceiling duct<br />

ACC 00105 / ACC 00150 / ACC 00151<br />

Clear tubing 6 mm<br />

ACC 00105: 5m in blister pack<br />

ACC 00150: in 50m roll<br />

ACC 00151: reinforced, 50m roll<br />

Can be used for routing cooling pipes<br />

up to diameter 5/8" - 3/8"<br />

RECOMMENDED ACCESSORIES<br />

ACC 00205<br />

6 self-sealing fitting for<br />

condensate removal.<br />

For an SI 1082 pump sold individually,<br />

the connection should be made directly<br />

at the tank outlet.<br />

You can use connector ACC 00209<br />

Carry out an in situ test and prime the pump.<br />

To do this, gently fill with water using the priming squeezie bottle (ACC 00401).<br />

24 Installation - <strong>pumps</strong> with integrated detection<br />

25<br />

Installation - <strong>pumps</strong> with integrated detection

Piston <strong>pumps</strong> with remote detection<br />

SI 3080 /SI 3100 / SI 3200 / SI 2750 / SI 1730<br />

Piston <strong>pumps</strong> with remote detection<br />

SI 3080 / SI 3100 / SI 3200 / SI 2750 / SI 1730<br />

AIR<br />

CONDITIONING<br />

SILENT<br />

SI 3080, SI 3100 up to 10 kW /<br />

SI 3200 up to 20 kW<br />

DETECTION UNIT INSTALLATION<br />

The vent pipe allows the air to be bled from the detection unit. You are advised<br />

to use the 4 mm clear tube supplied. Its length allows the upper level of the<br />

tube to be slightly above the maximum level of the condensates drain tank. In<br />

the event of a fault, this avoids overspill (principle of communicating vessels).<br />

When commissioning, ensure that this breather tube does not contain any<br />

water.<br />

Do not use a longer tube than the one supplied.<br />

SI 2750<br />

up to 10 kW<br />

FRONT<br />

SI 1730<br />

up to 30 kW<br />

The detection unit can be connected either<br />

at the front or the rear.<br />

REAR*<br />

*Supplied as standard: outlet at back.<br />

Blank the unused outlet with the plug<br />

supplied.<br />

The detection unit can be connected in 3 ways:<br />

Assembly position of the detection unit<br />

0/+ 15° +/- 15°<br />

At the outlet of the<br />

condensate evacuation tube<br />

At the tank outlet<br />

Directly inside the tank<br />

Front outlet<br />

Position to<br />

be avoided<br />

Acceptable<br />

position<br />

Rear outlet<br />

Position to<br />

be avoided<br />

Acceptable<br />

position<br />

26<br />

Installation - <strong>pumps</strong> with remote detection<br />

27<br />

Installation - <strong>pumps</strong> with remote detection

Piston <strong>pumps</strong> with remote detection<br />

SI 3080 / SI 3100 / SI 3200 / SI 2750/ SI 1730<br />

Monoblock pump with tank<br />

EE 1650 Monoblock pump with integrated tank for air conditioners up to 30 kW<br />

AIR<br />

CONDITIONING<br />

AIR<br />

CONDITIONING<br />

Silent<br />

Powerful<br />

Carry out an in situ test and<br />

prime the pump. To do this,<br />

gently fill with water using the<br />

priming squeezie bottle<br />

(ACC 00401).<br />

EE 1650<br />

up to 30 kW<br />

tank: 0.5 l<br />

PUMP UNIT INSTALLATION<br />

INSTALLATION<br />

The recommended fitting positions for the<br />

pump are: (avoid all other positions)<br />

Acceptable<br />

position<br />

Recommended<br />

position<br />

The pump must not be<br />

splashed nor located in a<br />

damp environment.<br />

the pump collects<br />

the condensates via<br />

the gravity inlet<br />

(in the top)<br />

The pump can be connected in 2 ways:<br />

The pump is<br />

placed directly in<br />

the condensate<br />

collecting tank<br />

Vertical discharge guarantees that the non<br />

return valve is watertight.<br />

The electrical connection must always be<br />

above the water inlet/outlet.<br />

Ensure that the condensates<br />

pass<br />

through the pump in<br />

the correct direction<br />

(see arrow on unit)<br />

RECOMMENDED ACCESSORIES<br />

Water may accumulate from<br />

condensation in the tube or<br />

due to a leak from the clear<br />

tube/pump end piece<br />

connection.<br />

ACC 00205<br />

6 self-sealing fittings for<br />

condensate removal.<br />

To use an EE 1650 in a condensate collecting<br />

tank, where the condensates are fed from<br />

below, follow the procedure outlined below.<br />

CAUTION<br />

irreversible<br />

procedure<br />

RECOMMENDED ACCESSORIES<br />

Clean the filter<br />

every time the air<br />

conditioner is<br />

inspected<br />

ACC 00105 / ACC 00150 / ACC 00151<br />

ACC 17010<br />

ACC 00205<br />

ACC 00105/ACC 00150/ACC 00151<br />

Clear tubing 6 mm<br />

ACC 00105: 5m in blister pack<br />

ACC 00150: in 50m roll<br />

ACC 00151: reinforced, 50m roll<br />

In-line filter for SI 1730.<br />

6 self-sealing fittings for<br />

condensate removal.<br />

ACC 00105: 5 m in blister pack<br />

ACC 00150: in 50 m roll<br />

ACC 00151: reinforced, 50m roll<br />

28<br />

Installation - <strong>pumps</strong> with remote detection<br />

29<br />

Installation - monoblock <strong>pumps</strong> with tank

Monoblock impeller <strong>pumps</strong> with tank<br />

SI 1800 / SI 1805 / SI 1820 / SI 1822 / SI 1850<br />

Monoblock impeller <strong>pumps</strong> with tank<br />

SI 1800 / SI 1805 / SI 1820 / SI 1822 / SI 1850<br />

AIR<br />

CONDITIONING<br />

HEATING<br />

REFRIGERATION<br />

Dynamic<br />

SI 1800<br />

tank: 2 l<br />

SI 1820<br />

tank: 2 l<br />

SI 1805<br />

tank: 0.5 l<br />

SI 1822<br />

tank: 3.8 l<br />

SI 1850<br />

tank: 3.8 l<br />

INSTALLATION<br />

MAINTENANCE<br />

REMOVING THE VALVE<br />

The transport<br />

tear-off strip<br />

must be removed<br />

before starting.<br />

Inlet<br />

adaptor<br />

ACC 00225<br />

ACC 00230<br />

ACC 00240<br />

The pump<br />

collects the<br />

condensates<br />

via the inlet<br />

in the top.<br />

The inside of the pump<br />

must be regularly<br />

cleaned. For this we<br />

recommend that you<br />

use a solution containing<br />

5% bleach. Ensure that<br />

the float switches remain<br />

clean.<br />

MECHANICAL ASSEMBLY<br />

All monoblock impeller <strong>pumps</strong> have a reversible tank.<br />

Condensate inlet<br />

Condensate inlet<br />

on left<br />

on right<br />

ACC 00110<br />

Installation kit::<br />

1 x ACC 00225,<br />

1 X ACC 00230,<br />

1 X ACC 00240.<br />

RECOMMENDED ACCESSORIES<br />

ACC 00810<br />

for SI 1805, SI 1820<br />

Non return valve<br />

Ø 10 mm<br />

ACC 00601<br />

Control switch.<br />

Used to control an<br />

additional alarm.<br />

ACC 00125 / ACC 00126<br />

Clear tubing<br />

Ø10 mm, length 25 m<br />

ACC 00125: non-reinforced tube<br />

ACC 00126: reinforced tube<br />

ACC 00225/ACC 00230/ACC 00240<br />

Condensate inlet adapters<br />

ACC 00225: 1”, Ø 32 mm<br />

ACC 00230: 1” 1/4, Ø 32 mm<br />

ACC 00240: 1” 1/2, Ø 40 mm<br />

30<br />

Installation -<br />

monoblock impeller<br />

<strong>pumps</strong> with tank<br />

31<br />

Installation -<br />

monoblock impeller<br />

<strong>pumps</strong> with tank

Peristaltic <strong>pumps</strong><br />

PE 5000 / PE 5100 / PE 5200 / PE 6250<br />

Peristaltic <strong>pumps</strong><br />

PE 5000 / PE 5100 / PE 5200 / PE 6250<br />

PRACTICAL<br />

AIR<br />

CONDITIONING<br />

REFRIGERATION<br />

PE 5100<br />

Temperature<br />

sensor for the<br />

evaporator<br />

AIR<br />

CONDITIONING<br />

REFRIGERATION<br />

PE 5000<br />

PE 5003<br />

PE 5100<br />

There are 3 different models and therefore 3 possible installations:<br />

PE 5000<br />

OPERATION<br />

INSTALLATION PE 5000<br />

Condensates are removed from the air<br />

conditioning unit at the tank outlet via a<br />

6 x 9 mm tube and the PE 5003 connector<br />

supplied with the pump.<br />

Pump operation is dependent on the operation of the air conditioning compressor<br />

or whenever the system provides cooling. The pump will continue to<br />

run for three minutes after the compressor has stopped.<br />

Installation example for<br />

PE 5000 and PE 5100 <strong>pumps</strong><br />

Rubber Outlet<br />

Connector (supplied)<br />

PE 5003<br />

Ø6 mm<br />

connector<br />

(supplied)<br />

Replacement head<br />

PE 5001<br />

INSTALLATION PE 5100<br />

Condensates are removed from the air<br />

conditioning unit at the tank outlet via a 6<br />

x 9 mm tube and the PE 5003 connector<br />

supplied with the pump.<br />

OPERATION<br />

The pump switches on when the temperature<br />

difference across the coil as measured<br />

by the two sensors is more than 6°C.<br />

The pump stops 3 minutes after the temperature<br />

difference falls below 6° C.<br />

Replacement head available<br />

for peristaltic <strong>pumps</strong><br />

PE 5000 / PE 5100 / PE 5200<br />

32<br />

Installation - Peristaltic <strong>pumps</strong><br />

33<br />

Installation - Peristaltic <strong>pumps</strong>

Peristaltic <strong>pumps</strong><br />

PE 5000 / PE 5100 / PE 5200 / PE 6250<br />

Peristaltic <strong>pumps</strong><br />

PE 5000 / PE 5100 / PE 5200 / PE 6250<br />

AIR<br />

CONDITIONING<br />

REFRIGERATION<br />

AIR<br />

CONDITIONING<br />

REFRIGERATION<br />

PRACTICAL<br />

PE 5200 PE 6250<br />

Ø 10 mm tube<br />

PE 5200<br />

Carry out an in situ test<br />

and prime the pump. To<br />

do this, gently fill with<br />

water using the priming<br />

squeezie bottle (ACC00401).<br />

Press the test button on the PE<br />

5000 & PE 5100 to operate the<br />

pump for three minutes.<br />

INSTALLATION PE 5200<br />

The detection unit is connected to the<br />

condensate evacuation tube outlet or<br />

directly to the tank outlet. The pump is<br />

connected to the detection unit by a 6 x<br />

9 mm tube.<br />

OPERATION<br />

The pump operates when condensates<br />

enter the detection unit. In this configuration,<br />

a 230 V / 8 A NC alarm contact is<br />

available.<br />

MAINTENANCE PE 5000/ PE 5100<br />

PE 5200<br />

Replace the tube (PE 5002) at least every<br />

year and the pump head (PE 5001) every<br />

two years or as required. (Remove the<br />

4 screws, disconnect the connector and fit<br />

the new head).<br />

Very heavily contaminated condensates can be evacuated with this high<br />

flow rate pump and its 10 mm evacuation pipe.<br />

The accessory supplied (ACC 00601), to be secured in the condensate<br />

tank, switches the pump on and off. It can also be used as an alarm contact<br />

in the event of a tank overflow.<br />

RECOMMENDED<br />

ACCESSORIES for PE 6250<br />

ACC 00125 / ACC 00126<br />

Clear tubing<br />

Ø 10 mm, length 25 m<br />

ACC 00125: non-reinforced tube<br />

ACC 00126: reinforced tube<br />

RECOMMENDED<br />

ACCESSORIES<br />

for all peristaltic<br />

<strong>pumps</strong><br />

PE 5002<br />

Replacement tube<br />

for <strong>pumps</strong><br />

PE 5000, PE 5100<br />

and PE 5200<br />

ACC 00205<br />

6 self-sealing<br />

fittings<br />

condensate<br />

removal<br />

PE 5001<br />

Replacement head<br />

for <strong>pumps</strong><br />

PE 5000, PE 5100<br />

and PE 5200<br />

ACCESSORY<br />

SUPPLIED for PE 6250<br />

ACC 00601<br />

Float control switch. Used<br />

to control the pump or an<br />

alarm.<br />

ACC 00601<br />

Control switch.<br />

Used to control an additional<br />

alarm<br />

PE 5003<br />

Ø 6 mm / Ø 17 mm<br />

adaptor with rubber<br />

tube<br />

34<br />

Installation - Peristaltic <strong>pumps</strong><br />

35<br />

Installation - Peristaltic <strong>pumps</strong>

DOSING peristaltic pump<br />

PE 6000<br />

AIR<br />

CONDITIONING<br />

Wiring DIAGRAM for <strong>pumps</strong> SI 1082, DELTA PACK, SI 3080,<br />

SI 3100, SI 3200, EE 1650, SI 1730<br />

PREVENTATIVE<br />

Mains supply 230 V ~ 50/60 Hz<br />

P<br />

N<br />

EFFECTIVE AND PREVENTATIVE<br />

PE 6000<br />

Injecting disinfectant and anti-bacterial products* can sanitise air cooling towers<br />

and prevent the transmission of bacteria (Legionnaire's disease) and the<br />

formation of algae.<br />

(*products not supplied, usage frequency, concentration and dosage in accordance with<br />

product manufacturers' recommendations).<br />

Connector<br />

Pump<br />

P N C NC<br />

Lead<br />

Connection unit<br />

630 mA fuse<br />

Solenoid valve<br />

Compressor<br />

NC/NO alarm contact,<br />

only on SI 1730<br />

PROGRAMMABLE<br />

or<br />

• In 15 minute intervals on a front-mounted time clock.<br />

• Timer-controlled programmable injection duration of 2 - 18 minutes.<br />

ACCESSORIES SUPPLIED<br />

Accessory supplied<br />

Accessory supplied<br />

Accessory supplied<br />

Accessory supplied<br />

Ø 4 mm suction<br />

Ø 4 mm discharge<br />

Suction strainer<br />

Injection connec-<br />

tube (length 3m)<br />

tube (length 3m)<br />

tor with valve<br />

36<br />

37<br />

Installation - Connection

Wiring DIAGRAM for <strong>pumps</strong> SI 2750<br />

Wiring DIAGRAM for <strong>pumps</strong> PE 5000, PE 5100 AND PE 5200<br />

Mains supply 230 V ~ 50/60 Hz<br />

P N<br />

Detection connector<br />

630 mA fuse<br />

Solenoid valve<br />

Phase<br />

Neutral<br />

Compressor<br />

PE 5000<br />

Compressor<br />

P N<br />

C NCNO<br />

Audible signal<br />

Visual signal<br />

Phase<br />

Neutral<br />

PE 5100<br />

or<br />

and/or<br />

or<br />

The 8 A 250 V alarm contact<br />

(resistive) must be<br />

connected (PE 5200).<br />

Alarm<br />

C<br />

N.C.<br />

PE 5200<br />

Phase<br />

Neutral<br />

Wiring DIAGRAM for <strong>pumps</strong> SI 1800, SI 1805, SI 1820,<br />

SI 1822, SI 1850<br />

Mains supply<br />

230 V ~ 50/60 Hz<br />

P<br />

N<br />

*<br />

Pump<br />

NC/C<br />

alarm<br />

lead<br />

630 mA fuse<br />

Solenoid valve<br />

Compressor<br />

IMPORTANT<br />

The <strong>pumps</strong> must have<br />

a power supply that is<br />

independent to that of the air<br />

conditioner to ensure that<br />

they continue to operate<br />

if the refrigerating appliance<br />

breaks down.<br />

Adaptor unit<br />

or<br />

230 V<br />

48 V max<br />

* plug not supplied on SI 1800, SI 1822 and SI 1850<br />

38<br />

Installation - Connection<br />

39<br />

Installation - Connection

Alarm operating<br />

EXAMPLES<br />

Chilled water Monosplit and Multisplit<br />

Direct expansion Multisplit<br />

Production of<br />

chilled water<br />

Air conditioners<br />

Pumps<br />

External unit Air conditioners Pumps<br />

When the alarm is triggered, the pump solenoid valve is cut off<br />

and/or an audible or visual alarm is operated<br />

When the alarm is triggered, the pump solenoid valve is cut off<br />

and/or an audible or visual alarm is operated<br />

Direct expansion Monosplit<br />

External unit Air conditioners Pumps<br />

When the alarm is triggered, the pump compressor is cut off<br />

and/or an audible or visual alarm is operated.<br />

40<br />

Installation - alarm<br />

41<br />

Installation - alarm

ACCESSORIES*:<br />

LES ACCESSOIRES:<br />

ESSENTIALS LES INDISPENSABLES<br />

* Accessories are only guaranteed for the applications for which they are recommended.<br />

ACC 00209<br />

ACC 00210<br />

ACC 00211<br />

15 x 15 mm flexible connector used<br />

to drain the tank completely.<br />

90° elbow, 17 x 15 mm<br />

Ø 6 mm Tee connector<br />

Piston <strong>pumps</strong> for air conditioners up to 10 kW<br />

and up to 30 kW<br />

Centrifugal impeller method<br />

Peristaltic <strong>pumps</strong><br />

ACC 00100<br />

ACC 00105<br />

ACC 00150<br />

ACC 00151<br />

Installation kit SI 2750<br />

ACC 00105: 5m in blister pack<br />

ACC 00150: in 50m roll<br />

ACC 00151: reinforced, 50m roll<br />

ACC 00214<br />

ACC 00225<br />

ACC 00230<br />

ACC 00240<br />

ACC 00401<br />

ACC 00501<br />

To prevent siphoning when<br />

the discharge point is lower than the detector level<br />

Condensate inlet adaptors.<br />

Squeezie bottle: used to test the pump<br />

without removing the unit.<br />

10 double-sided stickers.<br />

ACC 00106<br />

Blond rubber 50 cm for SI 1082 / SI 2750 /<br />

SI 3080 / SI 3100 / SI 3200 / SI 1730<br />

ACC 00601<br />

Float control switch. Used to control the pump<br />

or an alarm SI 1800 / SI 1805 / SI 1820 /<br />

SI 1822 / SI 1850 / PE 5000 / PE 5100 / PE 6250.<br />

ACC 00110<br />

Installation kit comprising the following<br />

components: 1 X ACC 00225,<br />

1 X ACC 00230, 1 X ACC 00240.<br />

ACC 00703<br />

3 m extension for SI 2750 / SI 3080<br />

SI 3100 / SI 3200 / SI 1730 / PE 5200.<br />

ACC 00125<br />

ACC 00126<br />

Clear tube, 10 mm int. On 25 m coil<br />

ACC 00125: non-reinforced tube<br />

ACC 00126: reinforced tube<br />

ACC 00705<br />

5 m extension for SI 2750 / SI 3080<br />

SI 3100 / SI 3100 / SI 3200 / SI 1730 / PE 5200.<br />

ACC 00201<br />

Ø 17 / Ø 22 mm adaptor kit<br />

ACC 00801<br />

10 mm non return valves<br />

for SI 1805 / SI 1820.<br />

ACC 00202<br />

Ø 17 / Ø 32 mm adaptor kit<br />

ACC 00805<br />

5 non return valves for Ø 6 mm tube.<br />

ACC 00203<br />

Ø 17 / Ø 32 mm reduction for reducing flow<br />

ACC 17010<br />

In-line filter for SI 1730.<br />

ACC 00204<br />

5 Ø 6 mm straight connectors<br />

+ 5 Ø 6 mm elbow connectors.<br />

PE 5001<br />

Replacement head<br />

For <strong>pumps</strong> PE 5000 / PE 5100 / PE 5200<br />

ACC 00205<br />

6 condensate self-sealing evacuation connectors.<br />

PE 5002<br />

Replacement tube<br />

For <strong>pumps</strong> PE 5000 / PE 5100 / PE 5200<br />

ACC 00208<br />

90° elbow, 15 x 15 mm<br />

PE 5003<br />

Ø 17 mm - Ø 6 mm reduction<br />

for <strong>pumps</strong> PE 5000 / PE 5100 / PE 5200<br />

42<br />

Accessories<br />

43<br />

Accessories

QUALITY, GUARANTEE,<br />

SERVICE<br />

Our priorities<br />

At your service<br />

To anticipate your requirements, meet your expectations in full and provide<br />

total satisfaction:<br />

In practice, our quality policy continues in day to day life through the implementation<br />

of customer services:<br />

In 1997, <strong>Sauermann</strong> committed itself to implementing a quality policy in accordance<br />

with standard ISO 9002.<br />

In 2003, <strong>Sauermann</strong> applied to obtain standard ISO 9001 version 2000 and was<br />

successful in obtaining it.<br />

➜ Technical assistance which, with just one phone call, can provide you<br />

with advice and offer the best tips and information.<br />

➜ Products guaranteed for 24 months.<br />

Through regular internal audits, standard ISO 9001 version 2000 shows the<br />

total involvement at all levels of the company to ensure we constantly work<br />

towards:<br />

➜ An effective after sales department.<br />

(Products returned to the after sales department are analysed, thus<br />

helping to improve our products on a permanent basis).<br />

➜ Complying with our lead-times<br />

➜ Controlling our products<br />

➜ And improving our services.<br />

Our quality requirement continues through developing our products which<br />

are subject to certification with the main independent laboratories, in order<br />

to obtain the CE, VDE and ETL labels.<br />

44<br />

45

NOTES<br />

THE BENCHMARK RANGE OF CONDENSATE REMOVAL PUMPS<br />

46<br />

47

®<br />

SAUERMANN FRANCE<br />

Parc d’activités de l’Orée de Chevry<br />

Route de Férolles<br />

77173 CHEVRY-COSSIGNY / France<br />

Tél. : (+33) 01 60 62 06 06<br />

Fax : (+33) 01 60 62 09 09<br />

E-mail : info@sauermann.fr<br />

SAUERMANN N.A. Corp<br />

<strong>Sauermann</strong> NA Corp<br />

85 Nicon Court, Suite 1,<br />

Hauppauge, NY 11788 - USA<br />

Tél. : (+1) 631-234-7600<br />

Fax : (+1) 631-234-7605<br />

E-mail : sales@sauermann.us<br />

SAUERMANN ITALIA S.R.L.<br />

Via G. Golini 61/11<br />

40024 Castel S.Pietro Terme (BO) / Italy<br />

Tél. : (+39)-051-6951033<br />

Fax : (+39)-051-942254<br />

E-mail : info@sauermann.it<br />

SAUERMANN GmbH<br />

Kernerstrasse 18<br />

D-74223 FLEIN / Germany<br />

Tél. : (+49) 07131/399990<br />

Fax : (+49) 07131/399992<br />

E-mail : <strong>Sauermann</strong>-Flein@t-online.de<br />

SAUERMANN UK Ltd<br />

Units 7 - 9, Trident Business Park<br />

Amy Johnson Way<br />

Blackpool - Lancashire FY4 2RP<br />

United Kingdom<br />

Tél. : + 44 (0) 870 950 6378<br />

Fax : + 44 (0) 870 950 6379<br />

E-mail : sales@sauermann-uk.com<br />

www.sauermann<strong>pumps</strong>.com<br />

®<br />

is a registered trademark of <strong>Sauermann</strong> Industrie<br />

SAUERMANN SHANGHAI Co. Ltd.<br />

155 ZhangPu Road<br />

JuYuan Development Park<br />

JiaDing District<br />

Shanghai 201821 / P.R. China<br />

Tél. : (+ 86) 21 691 689 61<br />

Fax : (+ 86) 21 691 689 62<br />

E-mail : sales@sauermann.com.cn<br />

SAUERMANN Hong Kong Ltd<br />

Room 1106, Tower 1 , Lippo centre<br />

89, Queensway / Hong Kong SAR<br />

SCANDINAVIA, BALTICS, RUSSIA<br />

Parkgade 8<br />

6440 AUGUSTENBORG / Denmark<br />

Tél. : (+45) 74 47 10 78<br />

Mobil : (+45) 40 59 10 78<br />

E-mail : peter.remontius@get2net.dk<br />

PENíNSULA IBÉRICA<br />

C/Ribera del Sena, s/n-Edificio APOT-3°<br />

28042 MADRID / Spain<br />

Tél. : (+34) 637 74 74 59<br />

Fax : (+34) 91 532 87 37<br />

E-mail : castelaosauermann@lycos.es<br />

Doc UK LIV/7 - 11/07 - 5 000 ex GASOLINE