Glassfront BevMax 3 Vender - The Vending Center

Glassfront BevMax 3 Vender - The Vending Center

Glassfront BevMax 3 Vender - The Vending Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

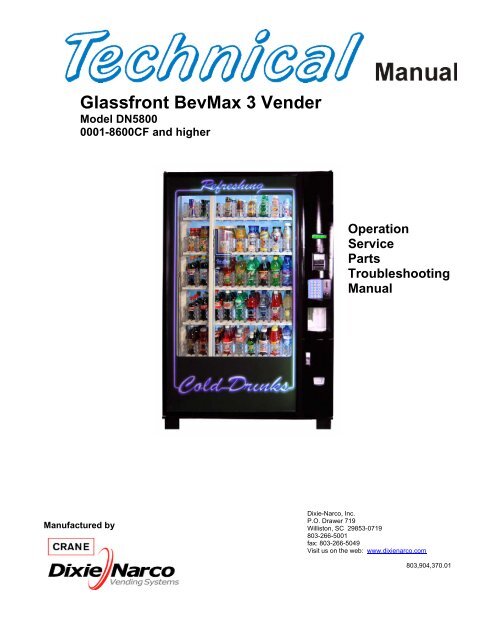

<strong>Glassfront</strong> <strong>BevMax</strong> 3 <strong>Vender</strong><br />

Model DN5800<br />

0001-8600CF and higher<br />

Operation<br />

Service<br />

Parts<br />

Troubleshooting<br />

Manual<br />

Manufactured by<br />

Dixie-Narco, Inc.<br />

P.O. Drawer 719<br />

Williston, SC 29853-0719<br />

803-266-5001<br />

fax: 803-266-5049<br />

Visit us on the web: www.dixienarco.com<br />

803,904,370.01

Table of Contents<br />

GENERAL INFORMATION.................................................................................. 4<br />

<strong>Vender</strong> Safety Precautions..................................................................................................4<br />

Product Identification ...........................................................................................................4<br />

Physical Characteristics ......................................................................................................4<br />

INSTALLATION & SETUP.............................................................................. 4 - 9<br />

Receiving Inspection ...........................................................................................................4<br />

Unpacking <strong>The</strong> <strong>Vender</strong>.................................................................................................. 4 - 5<br />

Electrical Requirements.......................................................................................................5<br />

Ground <strong>The</strong> <strong>Vender</strong>.............................................................................................................5<br />

Installation & Setup Instructions .................................................................................... 5 - 6<br />

Placing the <strong>Vender</strong> On Location.................................................................................... 6 - 7<br />

Leveling the <strong>Vender</strong>.............................................................................................................7<br />

Spacing the <strong>Vender</strong> .............................................................................................................7<br />

Installing Labels & Product ID Cards...................................................................................7<br />

Coin Changers And Other Accessories...............................................................................7<br />

Set Temperature Control .....................................................................................................8<br />

Loading the <strong>Vender</strong> .............................................................................................................8<br />

Loading the Coin Changer...................................................................................................8<br />

Power AC Distribution Box ..................................................................................................8<br />

<strong>Vending</strong> Machine Controller (VMC).....................................................................................8<br />

Keypad.................................................................................................................................8<br />

Digital Display......................................................................................................................8<br />

Refrigeration System ..................................................................................................... 8 - 9<br />

Shelf Assembly....................................................................................................................9<br />

Double Gate Assembly........................................................................................................9<br />

Slide / Pusher Assembly......................................................................................................9<br />

Motor Picker Assembly........................................................................................................9<br />

PROGRAMMING ........................................................................................ 10 - 25<br />

General ..............................................................................................................................10<br />

External Display Items.......................................................................................................10<br />

Normal Operation Messages.............................................................................................10<br />

Initial Programming.................................................................................................... 10 - 11<br />

Quick Reference Menu Items............................................................................................12<br />

Service Mode............................................................................................................ 13 – 15<br />

Test Mode................................................................................................................. 15 – 19<br />

Setup Mode 1 ........................................................................................................... 19 – 23<br />

Setup Mode 2 ........................................................................................................... 23 – 25<br />

MAJOR COMPONENT DESCRIPTION............................................................. 25<br />

AC Distribution Box ...........................................................................................................25<br />

GENERAL MAINTENANCE............................................................................... 26<br />

Power.................................................................................................................................26<br />

Cleaning.............................................................................................................................26<br />

CONTROL BOARD ........................................................................................... 27<br />

Controller Connections ......................................................................................................27<br />

TROUBLESHOOTING ............................................................................... 28 – 47<br />

XY Issues................................................................................................................... 28 - 30<br />

XY Not Working Flow Chart...............................................................................................31<br />

Plunger Home (Red Light) Flow Chart ..............................................................................32<br />

X Axis Home (Yellow Light) Flow Chart ............................................................................33<br />

Y Axis Home (Green Light) Flow Chart .............................................................................34<br />

XY Slams to Top/Right or Left Flow Chart ........................................................................35<br />

Picker Cup Not Working Flow Chart..................................................................................36<br />

Picker Cup at Wrong Location Y Axis Flow Chart.............................................................37<br />

Picker Cup at Wrong Location X Axis Flow Chart.............................................................38<br />

Delivery Port Door Flow Chart...........................................................................................39<br />

Coin Acceptance................................................................................................................40<br />

2

Bill Acceptors.....................................................................................................................40<br />

Control Board.....................................................................................................................40<br />

All Coins Rejected Flow Chart...........................................................................................41<br />

All Bills Rejected Flow Chart .............................................................................................42<br />

Incorrect Change Dispensed Flow Chart ..........................................................................43<br />

Selection Will Not Vend Flow Chart...................................................................................44<br />

Ice / Frost on Evaporator Flow Chart.................................................................................45<br />

Condensate on Outside of Product Door Flow Chart........................................................45<br />

Compressor Will Not Stop Flow Chart...............................................................................45<br />

Compressor Will Not Start Flow Chart ..............................................................................46<br />

Machine Not Cooling Flow Chart.......................................................................................47<br />

ELECTRICAL DIAGRAMS & SCHEMATICS ............................................ 48 – 56<br />

Block Diagram Domestic ...................................................................................................48<br />

Block Diagram Export........................................................................................................49<br />

<strong>Vender</strong> Wiring Diagram Cabinet (Domestic & Export) .............................................. 50 - 51<br />

<strong>Vender</strong> Wiring Diagram Door (Domestic & Export) ...........................................................52<br />

<strong>Vender</strong> Wiring Diagram Power & Lighting (Domestic only)...............................................53<br />

<strong>Vender</strong> Wiring Diagram Power & Lighting (Export only) ...................................................54<br />

Compressor Parts Diagram ...............................................................................................55<br />

AC Distribution Box J2 Port Test Voltages........................................................................56<br />

PARTS LIST AND DIAGRAMS ................................................................. 57 – 86<br />

Machine Front View.................................................................................................. 58 – 59<br />

Cabinet Detail Product Area ..................................................................................... 60 – 61<br />

Cabinet Detail Service Door Area............................................................................. 62 – 63<br />

XY Motor Picker Unit ................................................................................................ 64 – 65<br />

Picker Cup Assembly ............................................................................................... 66 – 67<br />

Service Door Outside ............................................................................................... 68 – 69<br />

Service Door Inside .................................................................................................. 70 – 71<br />

Gate Tray Detail........................................................................................................ 72 – 73<br />

AC Distribution Box ................................................................................................... 74 - 75<br />

Lighting ..............................................................................................................................76<br />

Refrigeration Unit Fin & Tube Condenser ................................................................ 77 – 78<br />

Electronics .........................................................................................................................79<br />

Harnesses................................................................................................................. 80 – 81<br />

Labels / Decals / Misc........................................................................................................82<br />

Screws & Nuts .......................................................................................................... 83 – 84<br />

Washers, Bolts, & Misc. Hardware........................................................................... 85 – 86<br />

3

VENDER SAFETY PRECAUTIONS<br />

Please read this manual in its entirety. This service<br />

information is intended for use by a qualified service<br />

technician who is familiar with proper and safe<br />

procedures to be followed when repairing, replacing or<br />

adjusting any Dixie-Narco vender components. All<br />

repairs should be performed by a qualified service<br />

technician who is equipped with the proper tools and<br />

replacement components, using genuine Dixie-Narco<br />

factory parts.<br />

REPAIRS AND/OR SERVICING<br />

ATTEMPTED BY UNQUALIFIED<br />

PERSONS CAN RESULT IN<br />

HAZARDS DEVELOPING DUE TO<br />

IMPROPER ASSEMBLY OR<br />

ADJUSTMENTS WHILE<br />

PERFORMING SUCH REPAIRS.<br />

PERSONS NOT HAVING A PROPER<br />

BACKGROUND MAY SUBJECT<br />

THEMSELVES TO THE RISK OF<br />

INJURY OR ELECTRICAL SHOCK<br />

WHICH CAN BE SERIOUS OR EVEN<br />

FATAL.<br />

PRODUCT IDENTIFICATION<br />

First production of <strong>BevMax</strong> 3 <strong>Vender</strong>s was July 2007.<br />

<strong>The</strong> production date of Dixie-Narco products is<br />

determined by the date code incorporated in the serial<br />

number.<br />

<strong>The</strong> vender serial number takes the form xxxx-yyyy<br />

zz. <strong>The</strong> first 4 digits (xxxx) identify the specific<br />

vender. <strong>The</strong> next 4 digits (yyyy) identify the<br />

manufacturing run that the vender was built in. <strong>The</strong><br />

last two alpha characters (zz) identify the quarter and<br />

the year the vender was built. <strong>The</strong> first alpha<br />

character identifies the quarter as follows:<br />

A= 1 st Quarter<br />

B= 2 nd Quarter<br />

C= 3 rd Quarter<br />

D= 4 th Quarter<br />

<strong>The</strong> second alpha character identifies the year:<br />

F = 2007 J = 2011<br />

G = 2008 K = 2012<br />

H = 2009 L = 2013<br />

I = 2010<br />

PHYSICAL CHARACTERISTICS<br />

HEIGHT<br />

WIDTH<br />

DEPTH CABINET<br />

DEPTH WITH<br />

SERVICE DOOR<br />

BASE<br />

SHIPPING WEIGHT<br />

DN5800<br />

72” (1828.8 mm)<br />

47” (1193.8 mm)<br />

32” (812.8 mm)<br />

33.5” (850.9 mm)<br />

4.5” (114.3 mm)<br />

764 lbs. (346kg)<br />

Glass door is 37.5” (876.3 mm) wide, 67” (1701.8<br />

mm) high<br />

RECEIVING INSPECTION<br />

DO NOT STORE THE VENDER OUTSIDE.<br />

Upon receipt, inspect the vender for any shipping<br />

damage. If there is any damage, have the delivery<br />

driver note the damage on the bill of lading and notify<br />

Dixie-Narco. Although the terms of sale are FOB<br />

shipping point, which requires the consignee to<br />

originate shipping damage claims, Dixie-Narco will<br />

gladly help if you must file a claim.<br />

UNPACKING THE VENDER<br />

Remove the stretch wrap, fiberboard edge protectors<br />

and corrugated front protector from the outside of<br />

vender.<br />

Do not store the vender with stretch<br />

wrap on. Stretch wrap could bond to<br />

the vender’s surface, which could<br />

damage the finish.<br />

Remove the shipping boards from the bottom of the<br />

vender. <strong>The</strong> shipping boards are attached by the<br />

leveling legs. To avoid unnecessary damage to the<br />

leveling legs or base, remove the shipping boards by<br />

using a 1-1/2 inch socket type wrench to unscrew the<br />

leveling legs. Be sure to replace the legs after<br />

removing the shipping boards.<br />

Once the vender is unpacked, check the recovery unit<br />

for any additional parts, price/ product labels,<br />

service/operation manual or other information<br />

concerning factory-equipped accessories such as coin<br />

mechanism and validator.<br />

4

WARNING: TO AVOID THE<br />

POSSIBILITY OF A FIRE<br />

HAZARD, DO NOT STORE<br />

ANYTHING OR ALLOW<br />

DEBRIS OF ANY KIND TO<br />

ACCUMULATE IN THE<br />

BOTTOM OF THE SERVICE<br />

AREA, IN AND AROUND THE<br />

REFRIGERATION<br />

COMPARTMENT OF THE<br />

CABINET, OR IN FRONT OF<br />

THE EVAPORATOR AND<br />

CONDENSER COILS.<br />

WARNING: ENSURE THAT<br />

POWER IS DISCONNECTED<br />

FROM THE VENDER BEFORE<br />

INSPECTING OR REPLACING<br />

THE LAMPS, OTHER<br />

ELECTRICAL COMPONENTS,<br />

OR WORKING WITH OR<br />

ADJUSTING THE VENDING<br />

MECHANISM. FAILURE TO<br />

COMPLY WITH THESE<br />

INSTRUCTIONS MAY<br />

SUBJECT THE USER TO THE<br />

RISK OF ELECTRICAL<br />

SHOCK OR MECHANICAL<br />

INJURY, WHICH CAN BE<br />

SERIOUS OR FATAL.<br />

ELECTRICAL POWER NEEDED<br />

Refer to the cabinet serial number plate to determine<br />

the correct voltage and frequency for the machine. In<br />

the US and Canada this is 120Vac, 60Hz, 1P. In<br />

Europe, Australia, and other export countries, this is<br />

220/230/240Vac, 50Hz, 1P depending upon your<br />

country voltage. <strong>The</strong> serial plate also specifies the<br />

ampere rating of the machine. This machine must be<br />

plugged into a properly rated receptacle with its own<br />

circuit protection (fuse or circuit breaker.<br />

DO NOT USE AN EXTENSION CORD.<br />

GROUND THE VENDER<br />

<strong>The</strong> vender is equipped with a three-wire power<br />

supply cord and MUST be plugged into a properly<br />

grounded outlet.<br />

DO NOT REMOVE THE GROUND<br />

PIN OR IN ANY WAY BYPASS,<br />

MODIFY, DEFEAT, OR DESTROY<br />

THE GROUNDING SYSTEM OF<br />

THE VENDER.<br />

If the outlet will not accept the power cord plug,<br />

contact an electrician to install a proper AC outlet.<br />

FAILURE TO COMPLY WITH<br />

THESE INSTRUCTIONS MAY<br />

SUBJECT THE USER TO THE RISK<br />

OF INJURY OR ELECTRICAL<br />

SHOCK WHICH CAN BE SERIOUS<br />

OR FATAL. PERIODICALLY<br />

INSPECT THE POWER SUPPLY<br />

CORD FOR DAMAGE. IF THE<br />

CORD BECOMES DAMAGED IT<br />

MUST BE REPLACED WITH THE<br />

SAME SIZE AND TYPE CORD.<br />

CONTACT DIXIE-NARCO FOR<br />

ASSISTANCE.<br />

INSTALLATION AND SETUP<br />

INSTRUCTIONS<br />

ELECTRONIC LOCK<br />

<strong>The</strong> electronic lock provided in the vender consists of<br />

a door mounted, motor driven 2 point latching system,<br />

cabinet mounted latch and strike system, an infrared<br />

controlled CPU, and a remote control key (FOB). <strong>The</strong><br />

design is modular and allows for easy field service.<br />

<strong>The</strong> electronic remote key (FOB) features a rolling<br />

code system which cannot be decoded if it is lost or<br />

stolen. After the vender has been unlocked, a new<br />

key can be programmed into it any number of times.<br />

If a key is lost or stolen, it is recommended you<br />

change the lock code in the field as soon as possible.<br />

Changing the lock code requires a new key and<br />

pressing the PROGRAM button on the lock inside the<br />

vender. <strong>The</strong> lock does not need to be changed for rekeying.<br />

Important: For security reasons all Electronic<br />

Door Lock <strong>Vender</strong>s are shipped less<br />

keys. Customers will need to contact<br />

the Electronic Door Lock<br />

manufacturer to order keys.<br />

A power bypass connector, located in the product<br />

delivery port, allows auxiliary power to be applied via<br />

a battery pack to the electronic lock in the event that<br />

power is not available or there has been a failure of<br />

the internal power supply. In the event of an<br />

emergency, battery power is applied to the connector<br />

and the door can be opened and closed using the<br />

FOB.<br />

<strong>The</strong> electronics uses an infrared transmission system,<br />

which functions similar to a television remote control.<br />

<strong>The</strong> transmission signal is line-of-sight, which requires<br />

you to aim the remote at a specific place at close<br />

range to prevent the accidental opening of several<br />

venders at the same time.<br />

5

TO OPEN THE ELECTRONIC DOOR LOCK:<br />

1. Plug the vender into a properly powered<br />

outlet.<br />

2. Hold the key FOB 0 to 3 inches in front of the<br />

Delivery Port Door and press the button on<br />

the key FOB.<br />

Note:<br />

<strong>The</strong> wide end of the FOB should face<br />

the door.<br />

3. <strong>The</strong> lock will begin releasing the door. <strong>The</strong><br />

display will indicate OPENED. After the motor<br />

has stopped running, you can pull the door<br />

open.<br />

TO CLOSE THE ELECTRONIC DOOR LOCK:<br />

CAUTION: DO NOT SLAM THE DOOR CLOSED.<br />

Slamming the door closed can damage the electronic<br />

locking device.<br />

1. Push the door to the cabinet until the lock<br />

motor starts. <strong>The</strong> display will indicate:<br />

CLOSED<br />

2. Continue to push the door for approximately 2<br />

to 3 seconds after the lock motor starts. <strong>The</strong><br />

lock will pull the door closed tightly.<br />

3. When the lock motor stops the door will be<br />

locked. Before leaving the vender, ensure<br />

that the door is locked.<br />

<strong>The</strong> electronic door lock assembly is supplied by Tri<br />

Teq Lock and Security. Dixie-Narco, Inc. does not<br />

carry parts for the Tri Teq Electronic Door Lock.<br />

For parts and assistance, please contact:<br />

Tri Teq<br />

701 Gullo<br />

Elk Grove Village, IL 60007<br />

Tel: 847-640-7002<br />

Fax: 847-640-7008<br />

Email: gary@triteqlock.com<br />

MANUAL LOCK<br />

Open the service door on the right side using the key<br />

provided in the coin return cup, or if shipped with a<br />

locking clip, remove the clip and install the lock.<br />

Ensure there is no power to the AC Distribution Box.<br />

On venders with a main power switch on the AC<br />

Distribution Box the switch needs to be in the OFF<br />

position. On venders with a main power quick<br />

disconnect plug on the AC Distribution Box the quick<br />

disconnect plug needs to be unplugged. Check that<br />

all connectors are firmly seated on the control board<br />

and at the various components on the service door<br />

(coin mech, keypad, etc.).<br />

Retrieve the main power plug from the hole in the rear<br />

of the vender and plug the cord in a properly<br />

grounded 120VAC, 15 Amp receptacle (U.S. and<br />

Canada).<br />

Open the service door and apply power to the AC<br />

distribution Box (if equipped with a bill acceptor, the<br />

acceptor should cycle twice). <strong>The</strong> display on the door<br />

will briefly show the software version in use as<br />

“Software ###.## (ie 080.01) followed by the default<br />

idle message “ENJOY A REFRESHING DRINK”, the<br />

fluorescent lamp should be lit and the cooling unit<br />

should start. If the display shows “OUT OF<br />

SERVICE”, or the cooling unit fails to start, refer to the<br />

TROUBLESHOOTING SECTION beginning on page<br />

28.<br />

SERVICE NOTE<br />

Battery Backup<br />

<strong>The</strong> battery backup is used to maintain the date and<br />

time in case of power interruptions, or any time the<br />

main power is off. When the vender is shipped, the<br />

battery is connected and memory is being maintained.<br />

If the vender is to be stored for long periods of time,<br />

disconnecting the battery is recommended. <strong>The</strong><br />

following steps will guide you through this procedure.<br />

• Open the service door, turn the main power<br />

switch to the off position or unplug the main<br />

power harness located on the front of the<br />

power box.<br />

• Locate the control board mounted on the rear<br />

wall.<br />

• Remove the battery from its holder (B 1).<br />

PLACING THE VENDER ON<br />

LOCATION<br />

!! CAUTION !!<br />

DO NOT TRANSPORT THE<br />

VENDER TO OR FROM THE<br />

LOCATION LOADED WITH<br />

PRODUCT OR DAMAGE TO THE<br />

VENDER MAY RESULT.<br />

<strong>The</strong> vender is intended for INDOOR USE ONLY. It<br />

should be kept out of direct sunlight and away form<br />

any heat source. This machine is not suitable for<br />

installation in an area where a water jet or hose and<br />

nozzle may be used.<br />

<strong>The</strong> vender must be on a solid, flat and level surface.<br />

Ensure the flooring can bear the weight load of a fully<br />

loaded vender (approximately 1109 lbs. or 413kg).<br />

<strong>The</strong> vender must be positioned close enough to an<br />

electrical outlet so that an extension cord is not<br />

required. If the machine will be subject to user misuse<br />

or vandalism, it is recommended that the vender be<br />

secured to the floor or wall as described in Dixie-<br />

Narco Technical Bulletin 344. Due to the large size<br />

6

and weight of the <strong>Vender</strong>, never attempt to move the<br />

<strong>Vender</strong> with a Hand Truck or Stair Climber. Use a<br />

pallet jack or <strong>Vender</strong>/Cooler Dollies at all times when<br />

moving the <strong>Vender</strong>. <strong>The</strong> vender should never be slid<br />

or pushed in place. Never side load the leveling legs;<br />

doing so will cause damage to the legs. Do not<br />

transport the vender to or from customer locations<br />

loaded with product, as damage may result due to<br />

excessive weight. Call the Dixie-Narco Technical<br />

Service Department or your Dixie-Narco<br />

Representative for assistance.<br />

LEVEL THE VENDER<br />

Adjust the front leveling legs, ensuring that an even<br />

gap exists between the glass door and the top<br />

security angle and receiver box, and then level the<br />

cabinet front to rear. A carpenter’s level will help<br />

verify that the vender is level. Leveling legs are<br />

adjusted using a wrench or socket 1 ½” in size. If the<br />

vender is to be used in a bank of equipment, check<br />

the top and sides for proper alignment. If you are<br />

unable to properly level the vender, select an alternate<br />

location. NEVER PLACE OBJECTS UNDER THE<br />

LEVELING LEGS OF THE VENDER<br />

DANGER<br />

THE VENDER MUST BE PROPERLY<br />

LOCATED AND LEVELED. IF THE<br />

MACHINE WILL BE SUBJECT TO<br />

USER MISUSE OR VANDALISM IT IS<br />

RECOMMENDED THAT THE<br />

VENDER BE SECURED TO THE<br />

FLOOR OR WALL AS DESCRIBED<br />

IN DIXIE-NARCO TECHNICAL<br />

BULLETIN 344 TO MINIMIZE THE<br />

RISK OF INJURY OR DEATH FROM<br />

TIPPING. CALL THE DIXIE-NARCO<br />

TECHNICAL SERVICE<br />

DEPARTMENT OR YOUR DIXIE-<br />

NARCO REPRESENTATIVE FOR<br />

ASSISTANCE.<br />

SPACE THE VENDER<br />

Do not block the rear of the vender. Maintain a<br />

minimum of 4 inches (10 cm) from the wall to ensure<br />

adequate airflow to the condenser and compressor.<br />

At the rear of the vender, make sure nothing obstructs<br />

the air exhaust at the bottom of the cabinet.<br />

WARNING<br />

TO AVOID THE POSSIBILITY OF A<br />

FIRE HAZARD, DO NOT STORE<br />

ANYTHING OR ALLOW DEBRIS OF<br />

ANY KIND TO ACCUMULATE IN THE<br />

BOTTOM OF THE DOOR, IN THE<br />

BOTTOM OF THE SERVICE AREA,<br />

IN AND AROUND THE<br />

REFRIGERATION COMPARTMENT<br />

OF THE CABINET, OR IN FRONT OF<br />

THE EVAPORATOR AND<br />

CONDENSER COILS.<br />

INSTALLING PRICE LABELS<br />

Pricing labels included in the literature package kit.<br />

<strong>The</strong>y range in price from .25 to 9.95. Remove the<br />

pricing label sheets from the service manual package<br />

and gently remove the label corresponding to the<br />

vend price of each selection by tearing at the<br />

perforation. <strong>The</strong> label is installed at the top of the<br />

front knuckle. Once installed, push the label firmly<br />

against the front of the knuckle. This will insure the<br />

label is locked in place.<br />

INSTALLING PRODUCT ID CARDS<br />

To assist with consistent loading, product ID cards are<br />

included for the slide assemblies with every vender<br />

and should be installed into the product pusher to<br />

designate to the route driver which product the column<br />

is set for. To install the flavor card, simply detach it<br />

from the sheet at the perforation and slide it into the<br />

slots in the product pusher.<br />

COIN CHANGERS & OTHER<br />

ACCESSORIES<br />

<strong>The</strong> vender can have an MDB coin changer installed<br />

and can have an MDB bill acceptor installed as well.<br />

Note: <strong>BevMax</strong> 3 will work with an MDB bill acceptor<br />

only. If the MDB coin changer and other MDB<br />

accessories are not factory installed, refer to the<br />

instructions received form the manufacturer of the<br />

MDB coin changer and other MDB accessories for<br />

proper set-up and installation.<br />

<strong>The</strong> vender will support the following Domestic MDB<br />

coin changers:<br />

Coinco 9302GX, USG-701 Quantum<br />

Mars TRC-6510, TRC-6512, TRC-4010<br />

Conlux CCM-5G 1-2-3-4-5<br />

<strong>The</strong> vender will support the following domestic MDB<br />

Bill validators:<br />

Coinco BA-30 B, BA-50B Coinco Mag 50<br />

Mars VN 2512 Conlux NBM-3000 Series<br />

<strong>The</strong> vender will support MDB card readers.<br />

7

SETTING THE TEMPERATURE<br />

CONTROL<br />

This vender is equipped with an electronic<br />

temperature sensor and a manual defrost thermostat.<br />

This temp sensor is factory pre-set to maintain a<br />

cabinet temperature of 37 degrees Fahrenheit. It is<br />

also a good practice to ensure the proper operating<br />

temperature prior to installing the vender on location.<br />

To set the temperature, apply power to the vender<br />

and allow it to run for several hours with the glass<br />

door closed or until the minimum cabinet temperature<br />

is achieved. <strong>The</strong>n, using the method below, verify the<br />

temperature inside the cabinet:<br />

With an electronic temperature sensor, use the<br />

keypad on the service door to show cabinet<br />

temperature in Fahrenheit by pressing the F key<br />

followed by the asterisk () key or in Centigrade by<br />

pressing the C key followed by the asterisk key. <strong>The</strong><br />

temperature will be shown on the digital display<br />

located on the front of the service door.<br />

<strong>The</strong> defrost control is located on the side of the<br />

refrigeration unit. <strong>The</strong> defrost control is preset and is<br />

not adjustable.<br />

LOADING THE VENDER<br />

CAN/BOTTLE DRINK TRAYS<br />

<strong>The</strong> <strong>BevMax</strong> 3 <strong>Vender</strong> does not require spacers or<br />

shims to vend most packages. Load product in each<br />

column one package at a time insuring that the<br />

package being loaded is in front of the product<br />

pusher. Insure that the package is stable within the<br />

column (doesn’t move excessively from side to side).<br />

After loading the vender, test vend each column to<br />

insure proper operation. Please contact a Service<br />

Representative or refer to the proper Technical<br />

Publication for any special settings you may need.<br />

LOADING CHANGE TUBES<br />

<strong>The</strong> changer tubes can be loaded using one of the<br />

following methods:<br />

1. Load the coin mechanism with coins to the<br />

desired level by inserting coins in the loading<br />

slots on the coin tube front.<br />

Minimum coin tube levels are:<br />

6-8 nickels<br />

7-8 dimes<br />

5-6 quarters<br />

Note: A low coin level in the coin tubes will<br />

interfere with operation of the bill validator.<br />

2. For exact cash accountability and to insure<br />

maximum dollar bill acceptance, load the<br />

mechanism utilizing the coin insert slot on the<br />

front of the vender while in the coin tube<br />

fill/dispense mode in the test menu. (see<br />

page 18 in the programming section for more<br />

information)<br />

(For additional information about coin mechanism,<br />

refer to the manufacturer’s instructions.)<br />

POWER AC DISTRIBUTION BOX<br />

<strong>The</strong> power distribution box is where the 120VAC input<br />

voltage is broken down to the main operating voltages<br />

of the vender (24 VAC and 12 VAC) by a transformer.<br />

Those voltages are sent to the controller via the P1 (3<br />

pin) connector. It also contains 3 fuses that protect<br />

the VMC, transformer, and motors. <strong>The</strong> power<br />

distribution box also distributes AC power to the lights,<br />

evaporator fan, and refrigeration system, which are<br />

always energized when the vender is powered up. It<br />

is located inside the service area, mounted to the<br />

back wall.<br />

VENDING MACHINE CONTROLLER (VMC)<br />

<strong>The</strong> vending machine controller is the heart of the<br />

Glass Front <strong>Vender</strong> and is located on the rear wall<br />

inside the service area. It is flash programmable and<br />

may or may not include the program chip (EPROM),<br />

which controls all aspects of the vender. It also<br />

contains the power supply which regulates the<br />

voltages required to operate the motors as well as the<br />

coin mechanism, digital display and all logic functions<br />

in the vender.<br />

Keypad<br />

<strong>The</strong> keypad is located on the front of the service door.<br />

It consists of a 6 inch X 3 inch matrix, membrane<br />

switch pad and an overlay. <strong>The</strong> pad utilizes the letters<br />

A thru F on the left side and numbers 1 thru 0 along<br />

with the symbol and Clr to the right. <strong>The</strong> keypad is<br />

where the vender programming is accomplished and<br />

where the customers make their selections.<br />

DIGITAL DISPLAY<br />

<strong>The</strong> digital display is located directly above the<br />

keypad on the front of the service door. It is used to<br />

convey information to the consumer as well as to the<br />

person programming the vender.<br />

REFRIGERATION SYSTEM<br />

<strong>The</strong> refrigeration system is a single piece unit and is<br />

hermetically sealed. In the EM2001 model consist of<br />

a ½ horsepower compressor, with a single fin and<br />

tube style condensing unit with one fan, the<br />

condensation overflow pan and the evaporator. <strong>The</strong><br />

evaporator is located behind the panel on the back<br />

right side of the cooling compartment directly adjacent<br />

to the bottom shelf. <strong>The</strong> remainder of the unit is<br />

located behind the refrigeration unit cover panels,<br />

mounted in the bottom of the cabinet. This unit is<br />

designed for easy removal and replacement from the<br />

front of the vender as a complete assembly. An<br />

electronic thermostat regulates the cabinet<br />

temperature. <strong>The</strong> bulb of the thermostat is attached<br />

8

to the evaporator coils and reads the temperature of<br />

air being pulled in to the evaporator coil.<br />

SHELF ASSEMBLY<br />

Typically, there are 5 shelf assemblies in every<br />

vender; however, this can vary depending upon the<br />

configuration specified at the time of ordering. Each<br />

can/bottle shelf consists of 9 columns. Each shelf is<br />

capable of holding a variety of packages. <strong>The</strong> shelf<br />

assembly consists of the tray, where all of the<br />

following parts are mounted: Double Gate assembly,<br />

and the slide/pusher assembly. <strong>The</strong>se items are<br />

discussed in detail below.<br />

DOUBLE GATE ASSEMBLY (Can/Bottle<br />

Trays)<br />

<strong>The</strong> double gate assembly is mounted on the front<br />

portion of the tray assembly and contains the vending<br />

mechanism. Incorporated in the gate assembly are<br />

the front and rear knuckle assemblies as well as the<br />

product kicker. In standby operation, the front knuckle<br />

is in the blocking position, which holds the front<br />

displayed product in position to be vended. <strong>The</strong> rear<br />

knuckle assembly is in a flat position, which allows<br />

product to enter the gate area, and the kicker is flush<br />

to the rear knuckle assembly. A stainless steel pin is<br />

inserted through the rear most portion of the front<br />

knuckle assembly and connects to a gear box below<br />

the tray. When a selection is made, the plunger<br />

pushes the lever toward the back of the tray. At the<br />

same time the front knuckle is opened into a flat<br />

position, the rear knuckle is closed to a blocking<br />

position, holding the remaining product out of the gate<br />

area, and the kicker is extended to firmly push the<br />

front displayed product off of the tray. <strong>The</strong> plunger is<br />

energized for approximately 1-½ seconds to allow<br />

ample time for the displayed product to be ejected<br />

from the shelf. <strong>The</strong> plunger is then released and the<br />

front knuckle returns to the blocking position, the rear<br />

knuckle and kicker return to their standby position and<br />

the next product slides into the vend display position.<br />

MOTOR PICKER ASSEMBLY<br />

<strong>The</strong> motor picker assembly is located on the XY door<br />

vend mechanism. Its purpose is to pick the product<br />

from the column and deliver the product to the<br />

delivery port. <strong>The</strong> motor picker assembly is mounted<br />

on the XY assembly and bolts in position.<br />

<strong>The</strong> X axis runs left to right. <strong>The</strong> X axis assembly is<br />

cabinet mounted to prevent any cabinet torque and<br />

has one belt to synchronize the top and bottom when<br />

the X moves left or right.<br />

<strong>The</strong> Y axis runs up and down and has the Picker Cup<br />

Assembly attached. A top channel is used to contain<br />

and hide the e chain and wiring.<br />

Both X and Y motors have encoders for positioning.<br />

SLIDE/PUSHER ASSEMBLY (Can/Bottle<br />

Trays)<br />

<strong>The</strong> slide/pusher is located on the bottom of each<br />

product column. Its purpose is to provide a slick,<br />

friction resistant surface for the product to rest on.<br />

<strong>The</strong> tall product pusher is mounted on the top of the<br />

slide and incorporates a coil spring in the body that<br />

attaches to the bottom of the slide through a slit. This<br />

spring adds needed tension to insure that all products<br />

in the column remain tight against each other and are<br />

allowed to progress into the gate area. Periodic<br />

cleaning and lubrication of the slides is recommended.<br />

DO NOT USE SOLVENTS OR ABRASIVE<br />

MATERIALS TO CLEAN ANY PORTION OF THE<br />

TRAY.<br />

9

PROGRAMMING<br />

GENERAL INFORMATION<br />

In order to fully utilize the many features of your<br />

vender it is important that you first understand the<br />

options available and procedures for programming the<br />

vending controller unit (control board).<br />

All programming, testing, and service functions are<br />

accomplished by using the keypad in an easy to<br />

follow, display prompted format. <strong>The</strong>re are four modes<br />

of operation for servicing, testing, and setting up your<br />

vender. <strong>The</strong> modes of operation are accessed by,<br />

opening the service door, and pressing the service<br />

button on the control board.<br />

<strong>The</strong> service button will cycle through each of the four<br />

modes in turn: Service Mode, Test Mode, Set-Up<br />

Mode 1 and Set-Up Mode 2. In each of these modes,<br />

the “A” key is used to scroll through the available<br />

options/settings within that mode/selection. (Note: In<br />

each of the mode selections, pressing the character<br />

key next to the listed option will take you directly to<br />

that feature - see menu items chart on page 12.), the<br />

“” key is used as an enter key to select the currently<br />

displayed item/feature, and the “CLR” key is used as a<br />

done or exit key. Closing the service door or pushing<br />

the service door switch will exit the function you are<br />

currently in and place the vender back in service.<br />

EXTERNAL DISPLAY ITEMS<br />

(HOT KEYS)<br />

Allows the service technician to view several items via<br />

the display without opening the vender. <strong>The</strong>re are four<br />

options that can be viewed externally:<br />

1. Display temperature in degrees “C”. To<br />

view, press the “C” then press the key. <strong>The</strong><br />

display will then show the vender’s inside<br />

temperature in degrees “C”.<br />

2. Display date/time. To view, press the “D”<br />

key, then press the “” key. <strong>The</strong> display will<br />

then show the current date and time.<br />

3. Display temperature in degrees “F”. To<br />

view, press the “F” key, then press the “”<br />

key. <strong>The</strong> display will show the vender’s inside<br />

temperature in degrees “F”.<br />

4. Display current software revision. To view,<br />

press the “B” key, then press the “” key. <strong>The</strong><br />

display will then show the current software<br />

revision in the controller.<br />

NORMAL OPERATION MESSAGES<br />

At initial power-up, the program will start and the<br />

display will briefly show the software version in use as<br />

Software ###.## (i.e. 080.01), followed by the default<br />

idle message, “ENJOY A REFRESHING DRINK”.<br />

INITIAL PROGRAMMING<br />

DATE/TIME<br />

To set date/time enter “SETUP MODE 1” by opening<br />

the service door and pressing the Service Button<br />

three (3) times. Press the number “5” and<br />

“DATE/TIME” will show on display. Press the “” key<br />

and display will show the current year, month, date,<br />

and time setting currently in the system in following<br />

format: 2005 Apr 28 15:45 with the year highlighted.<br />

Press the numbers to enter the current year and<br />

Month will then be highlighted. To change the month<br />

press the A key to scroll forward through the months<br />

or the B key to scroll backward through the months.<br />

With the correct month showing, press the “” key to<br />

save and Date will then be highlighted. Press the<br />

numbers to enter the current date and then the hour<br />

will then be highlighted. Note: Hours are shown in 24<br />

hour format. Press the numbers to enter the current<br />

hour and then the minutes will then be highlighted.<br />

Press the numbers to enter the current minutes. <strong>The</strong><br />

display will then change to show “OK? =Y (Yes)<br />

CLR = N (No)” and the setting you entered. You must<br />

press Key to save the new date and time entered.<br />

Pressing CLR Key will revert to the date and time<br />

setting. Press the “CLR” key to return to “SETUP<br />

MODE”.<br />

SET PRICES<br />

To set the prices enter the “SERVICE MODE” by<br />

opening the service door and pressing the Service<br />

Button once. Allows the setting of regular and<br />

secondary prices for an individual item, a complete<br />

tray, or the entire machine. Factory setting is $99.95.<br />

Press the number “7” on the keypad and the display<br />

will show “SET PRICE”. Press the “” key and the<br />

display will show “1 = Regular Pricing, 2 = Secondary<br />

Pricing”. To set regular prices press number 1 key<br />

and display will show “Regular $##.##”. To set price:<br />

1. All selections. Press the keypad numbers of<br />

the price you wish to use. As numbers are<br />

entered the numbers will shift in from the right<br />

as they are entered. Note: <strong>The</strong> CLR key will<br />

remove the last # of the price. Once the<br />

desired price is showing on the display press<br />

the “” key and the display will show<br />

“PR$##.## All Set”, press “*” to set more<br />

prices or CLR to return to SET PRICES.<br />

Press CLR Key again to return to SERVICE<br />

MODE.<br />

2. One tray. Press the keypad numbers of the<br />

price you wish to use. As numbers are<br />

entered the numbers will shift in from the right<br />

as they are entered. Note: <strong>The</strong> CLR key will<br />

remove the last # of the price. Once the<br />

desired price is showing on the display press<br />

the tray letter desired for setting price. Press<br />

“” and display will show “PR $##.## B(tray<br />

letter) Row Set”, press “*” to set more prices<br />

10

or CLR to return to SET PRICES. Press CLR<br />

Key again to return to SERVICE MODE.<br />

3. Single selection. Press the keypad numbers<br />

of the price you wish to use. As numbers are<br />

entered the numbers will shift in from the right<br />

as they are entered. Note: <strong>The</strong> CLR key will<br />

remove the last # of the price. Once the<br />

desired price is showing on the display press<br />

the selection desired for setting price. Press<br />

“” and display will show “PR $##.## B1<br />

Selection Set”, press “” to set more prices or<br />

CLR to return to SET PRICES. Press CLR<br />

Key again to return to SERVICE MODE.<br />

<strong>The</strong> last price entered for a selection is the price that<br />

will be used. For example, If one price on the A tray<br />

was set to $1.50 using option 3 above and you wish to<br />

change the remaining selections on that tray using<br />

option 2, the pricing for the entire tray would take<br />

precedence. Conversely, if the price was set using<br />

option 2 first followed by the single selection using<br />

option 3, the pricing for the remainder of the shelf<br />

would remain and the new price for the single<br />

selection would change to the new value.<br />

Press the “CLR” key to return to “SERVICE MODE”.<br />

SET NOT AVAILABLE TIMES<br />

Password protected. Before entering or changing this<br />

setting you must enter the password if one has been<br />

assigned. This mode allows up to 4 different time<br />

periods that use of the machine may be restricted.<br />

To set Not Available Times enter the “SETUP MODE<br />

1” by opening the service door and pressing the<br />

Service Button 3 times. Press the number 3 key; the<br />

display will show “SET NOT AVAIL TIME”. Press the<br />

“” key and the display will show “Select Block (1 –<br />

4): Press number 1 Key to set Select Block 1 available<br />

settings, Key 2 for Select Block 2, etc… Once you<br />

select the Select Block # you wish to set the display<br />

will show “Start MTWTFSS Stop 1 00:00 NNNNNNN<br />

00:00” with the start time hour highlighted. Press the<br />

numbers to enter the hour you wish to start select<br />

block (Note: hour setting is in 24 hour format.) and<br />

then the minutes will be highlighted. Press the<br />

number keys to enter the minutes and then the first<br />

day of the weeks current setting will be highlighted.<br />

To change the setting to no press key 2, to yes press<br />

key 1. This will change each setting left to right one<br />

day at a time until all are set then Stop time hour will<br />

be highlighted. Press the numbers to enter the hour<br />

you wish to stop select blocking and the minutes will<br />

be highlighted. Press the numbers to set the minutes<br />

and the display will show “OK? = Y CLR = N” press<br />

the Key to save these settings or CLR Key not to<br />

save settings and display will change to show which<br />

selections are assigned to this block. Press Key<br />

and display will show “Enter Selection”. Press the<br />

Keys of the selections you wish to disable followed by<br />

and display will show “Disabled Continue? = Y<br />

CLR = N”. Note: If you press a tray letter (ie A)<br />

followed by the Key that entire tray will be set to be<br />

disabled. Once you have selected all settings and the<br />

display shows “Disabled Continue? Or Enabled<br />

Continued? Note: display must show Display<br />

Enabled for the selection to shut down. = Y CLR<br />

= N (note: pressing clear will delete all settings you<br />

just set), press the CLR to return to “SET NOT AVAIL<br />

TIME”. Press CLR again to return to “SETUP MODE<br />

1”. Once completed go to Test Mode, Not Available<br />

Mode (Key 3) and turn on Not Available Mode.<br />

11

BEVMAX 3 SERVICE MODE MENU ITEMS<br />

(080.51 Menu shown)<br />

= enter selected mode, CLR = return to previous prompt<br />

SERVICE MODE<br />

A Next Item<br />

B Cash Box<br />

C Sales<br />

D Display Temperature<br />

E Set Refrig Temp<br />

F Clear Totals<br />

1 Number Sold<br />

2 Disable Item<br />

3 Sales by Column<br />

4 Escrow<br />

5 Force Vend<br />

6 Set Temperature (F or C)<br />

7 Set Prices (Regular & Secondary)<br />

8 Set Shelf Location (G, M1, M2, D, E, E1)<br />

9 Relay Toggle<br />

0 Clear Errors<br />

SETUP MODE 1<br />

A Next Item<br />

B Enter Message<br />

C Clear Message<br />

D Enable/Disable $<br />

E Set Happy Hour Time<br />

F Master Reset<br />

1 Machine Number<br />

2 Set Happy Hour<br />

3 Set Not Avail. Time<br />

4 Consumer Overpay<br />

5 Date/Time<br />

6 Total Sales<br />

7 Health Control<br />

8 Update Software<br />

9 Set Lights Off Time<br />

0 Enter New Password<br />

TEST MODE<br />

A Next Item<br />

B List Errors<br />

C Light Timer<br />

**D Test Mode - Not Used<br />

E Keypad Test<br />

F Factory Diagnostics<br />

1 Tube Fill/Dispense<br />

2 Daylight Savings Time<br />

3 Not Available Mode<br />

4 Credit Timer Mode<br />

5 Door Open<br />

6 Power Out<br />

7 Test Health Guard<br />

8 Display Health Guard<br />

9 Test Vend<br />

0 Show Checksums<br />

SETUP MODE 2<br />

A Next Item<br />

B STS Enable<br />

C Custom STS<br />

D Default STS<br />

E Display STS<br />

F Set NoVend Limit<br />

1 Multivend<br />

2 Set Language<br />

3 Sold Out Enable<br />

4 Price Display<br />

5 Storage Temp Enable<br />

6 Interval Clearing (On/Off)<br />

7 Set Lights Off<br />

8 Set Refrig Temp<br />

9 Set Storage Time<br />

0 Set Storage Temp<br />

*Note: All menu items with the ** are not available in<br />

the current <strong>BevMax</strong> 3 <strong>Vender</strong> programming.<br />

Note: all items in Italics under SETUP MODES<br />

require password entry for access if one has been<br />

assigned.<br />

FACTORY DEFAULT REQUIRES NO PASSWORD<br />

UNTIL NEW PASSWORD OTHER THAN 0000 IS<br />

ENTERED.<br />

Menu items shown above reflect software revision<br />

804,924,08x.x1 and higher<br />

Service Mode Pages 13 through 15<br />

Test Mode Pages 15 through 19<br />

Setup Mode 1 Pages 19 through 23<br />

Setup Mode 2 Pages 23 through 25<br />

12

SERVICE MODE MENU ITEMS<br />

Note: Menu items with the ** are not currently<br />

available.<br />

SERVICE MODE<br />

Enter SERVICE MODE by opening the service door<br />

and pressing the Service button once. <strong>The</strong> display<br />

will read “SERVICE MODE”. <strong>The</strong> following choices<br />

are now available:<br />

NEXT ITEM - Press key “A”<br />

CASH BOX - Press key “B”<br />

Shows the amount of change diverted to the cash<br />

box from the coin mechanism since the last CLEAR<br />

TOTALS or MASTER RESET. To view the cash box<br />

totals, press the letter “B” on the keypad and the<br />

display will show “CASH BOX”, then press the “”<br />

key and the display will show Cash Box $#.##.<br />

Press the “CLR” key to return to “CASH BOX”.<br />

Press the “CLR” key to return to “SERVICE MODE”<br />

or press the “A” key to advance to the next menu<br />

item below.<br />

SALES - Press key “C”<br />

Shows total sales since last CLEAR TOTALS or<br />

MASTER RESET. This total includes change not<br />

diverted to the cash box and still being held in coin<br />

mechanism escrow tubes To view the total sales<br />

press the letter “C” on the keypad and the display<br />

will show “SALES”, then press the “” key and the<br />

display will show Sales #.##. Press the “CLR” key to<br />

return to “SALES”. Press the “CLR” key to return to<br />

“SERVICE MODE” or press the “A” key to advance<br />

to the next menu item below.<br />

DISPLAY TEMPERATURE - Press key “D”<br />

Shows the cabinet temperature in degrees Celsius<br />

or degrees Fahrenheit. Press the letter “D” on the<br />

keypad. <strong>The</strong> display will show ”Display<br />

Temperature”. Press the “” key and the display<br />

will show “Display: ON (or OFF) Press “*” – turn OFF<br />

(or ON)”. Press the Key to toggle on/off or press<br />

the CLR Key to not change settings. If “on” is<br />

selected the Display will change to “Set<br />

Temperature Unit Degrees F (or C) showing the<br />

current setting temperature will be displayed. Press<br />

F for Fahrenheit or C for Celsius. Press the Key<br />

to save and return to “Display Temperature.” Press<br />

the “CLR” key to return to “SERVICE MODE” or<br />

press the “A” key to advance to the next menu item<br />

below.<br />

SET REFRIG TEMP – Press Key “E”<br />

Allows the service technician to set the average<br />

product temperature (set point) for initial pull down<br />

and reload recovery. Press the letter “E” on the<br />

keypad and display will show “SET REFRIG TEMP”.<br />

Press the “” key on the keypad and the display will<br />

read “tt.tx” where x is Fahrenheit or Celsius and tt.t<br />

is the degrees. To change the set point press the<br />

key numbers you wish the set point to be<br />

(temperature set must be between 32 and 75<br />

degrees F). Press the “” key to save the new set<br />

point temperature and return to “SET REFRIG<br />

TEMP”. Press the “CLR” key to return to “SERVICE<br />

MODE” or press the “A” key to advance to the next<br />

menu item below.<br />

CLEAR TOTALS - Press key “F”<br />

Allows the service technician to clear totals in CASH<br />

BOX, SALES, NUMBER SOLD, DOOR OPENINGS,<br />

POWER OUTAGES, SALES BY COLUMN, and all<br />

other interval data. Press the letter “F” on the<br />

keypad and the display will show “CLEAR TOTALS”.<br />

Press the “” key, the display will read Clear Interval<br />

Data? = Y CLR = N. Press the “CLR” key to return<br />

to “Clear Totals” with out resetting the totals. Press<br />

the selection you wish to use and display will return<br />

to “Clear Totals”. Press the “CLR” key to return to<br />

“SERVICE MODE” or press the “A” key to advance<br />

to the next menu item below.<br />

NUMBER SOLD - Press key “1”<br />

Shows the total number of items sold since the last<br />

CLEAR TOTALS OR MASTER RESET. Press the<br />

number “1” on the keypad and the display will show<br />

“NUMBER SOLD”. Press the “” key and the<br />

display will show “Number Sold #”. Press the “CLR”<br />

key to return to “Number Sold”. Press the “CLR” key<br />

to return to “SERVICE MODE” or press the “A” key<br />

to advance to the next menu item below.<br />

ENABLE ITEM - Press key “2”<br />

Allows an individual selection, a complete tray, or<br />

the entire machine to be enabled or disabled. This is<br />

most commonly used when a selection is out of<br />

order and you are awaiting parts and do not want<br />

the customer to utilize that selection. Press the<br />

number “2” on the keypad and the display will show<br />

“ENABLE ITEM”. Press the “” key and the display<br />

will read “Enter Selection”. <strong>The</strong>re are now three<br />

choices:<br />

1. Pressing the “” key will toggle between<br />

enabled and disabled for the entire machine,<br />

the display will show the new state i.e.<br />

enabled or disabled and display will show<br />

“Blocked (Unblocked) Continue? = Y CLR<br />

= N.<br />

2. Pressing a tray selection followed by “” will<br />

show the new state of that tray. (For<br />

example, pressing “A*” will show the new<br />

state for the A tray, the display will show the<br />

new state i.e. enabled or disabled and<br />

13

display will show “A Blocked (Unblocked)<br />

Continue? = Y CLR = N.<br />

3. Pressing an item selection will show the new<br />

state of that item; for example, pressing “A1”<br />

will show the new state of that item, the<br />

display will show the new state i.e. enabled<br />

or disabled and display will show “A1<br />

Blocked (Unblocked) Continue? = Y CLR<br />

= N.<br />

If a selection has been disabled in this mode and the<br />

customer tries to purchase from the programmed<br />

selection(s), the vender will display “SELECT<br />

ANOTHER ITEM”. Press the CLR Key to show all<br />

items that are blocked or the Key to disable more<br />

items. Press the “CLR” key to return to “Enable<br />

Item”. Press the “CLR” key to return to “SERVICE<br />

MODE” or press the “A” key to advance to the next<br />

menu item below.<br />

SALES BY COLUMN - Press key “3”<br />

Shows the total number sold from each selection<br />

since the last CLEAR TOTALS or MASTER RESET.<br />

Press the number “3” on the keypad and the display<br />

will show “SALES BY COLUMN”. Press the “” key<br />

and the display will read “Select Column”. Select the<br />

column to be checked (the total number sold from<br />

that selection will be on the right side of the display<br />

and the item number will be on the left side of the<br />

display). Press the “CLR” key to return to “Sales by<br />

Column”. Press the “CLR” key to return to<br />

“SERVICE MODE” or press the “A” key to advance<br />

to the next menu item below.<br />

ESCROW - Press key “4”<br />

Allows a bill to be returned if the change return lever<br />

is pressed before a selection is made. Factory<br />

setting is ESCROW OFF. Press the number “4” on<br />

the keypad and the display will read “ESCROW<br />

OFF” or “ESCROW ON”, depending on the current<br />

state. Pressing the “” key toggle the vender from<br />

ESCROW OFF to ESCROW ON. Example: If<br />

“ESCROW OFF” is showing on the display, pressing<br />

the “” key will disable the escrow function and the<br />

display will read ESCROW ON. This feature only<br />

affects those machines with a bill validator installed.<br />

Press the “CLR” key to return to “Escrow”. Press the<br />

“CLR” key to return to “SERVICE MODE” or press<br />

the “A” key to advance to the next menu item below.<br />

FORCE VEND - Press key “5” (NOT<br />

AVIALABLE)<br />

Forces the customer to make a vend by inhibiting<br />

the coin return lever once the minimum vend price<br />

line has been met or exceeded <strong>The</strong> coin return lever<br />

will not be inhibited if there is not enough credit to<br />

vend the lowest priced item or if a vend failure has<br />

occurred. Factory setting is “FORCE OFF”. Press<br />

the number “5” on the keypad the display will read<br />

“FORCE OFF” or “FORCE ON”, depending on the<br />

current state. Pressing the “” key will toggle the<br />

state. Press the “CLR” key to return to “Force Vend”.<br />

Press the “CLR” key to return to “SERVICE MODE”<br />

or press the “A” key to advance to the next menu<br />

item below.<br />

SET TEMPERATURE SCALE- Press key “6”<br />

Allows the service technician to change the scale of<br />

the temperature in the vender to read in Fahrenheit<br />

or Celsius as needed. Press the number “6” on the<br />

keypad and the display will show “Set Temperature”.<br />

Press the “” key and the display will show “Set<br />

Temperature Unit Degrees F (or C)”. Press the C to<br />

display in Celsius or F to display in Fahrenheit.<br />

Press to save and display will return to “Set<br />

Temperature”. Press the “CLR” key to return to<br />

“SERVICE MODE” or press the “A” key to advance<br />

to the next menu item below.<br />

SET PRICES - Press key “7”<br />

To set the prices enter the “SERVICE MODE” by<br />

opening the service door and pressing the Service<br />

Button once. Allows the setting of regular and<br />

secondary prices for an individual item, a complete<br />

tray, or the entire machine. Factory setting is<br />

$99.95. Press the number “7” on the keypad and<br />

the display will show “SET PRICE”. Press the “”<br />

key and the display will show “1 = Regular Pricing, 2<br />

= Secondary Pricing”. To set regular prices press<br />

number 1 key and display will show “Regular<br />

$##.##”. To set price:<br />

1. All selections. Press the keypad numbers<br />

of the price you wish to use. As numbers<br />

are entered the numbers will shift in from the<br />

right as they are entered. Note: <strong>The</strong> CLR<br />

key will remove the last # of the price. Once<br />

the desired price is showing on the display<br />

press the “” key and the display will show<br />

“PR$##.## All Set”, press “” to enter more<br />

prices or CLR to exit to SET PRICE.<br />

2. One tray. Press the keypad numbers of the<br />

price you wish to use. As numbers are<br />

entered the numbers will shift in from the<br />

right as they are entered. Note: <strong>The</strong> CLR<br />

key will remove the last # of the price. Once<br />

the desired price is showing on the display<br />

press the tray letter desired for setting price.<br />

Press “” and display will show “PR $##.##<br />

B(tray letter) Row Set”, press “*” to set more<br />

prices or CLR to exit to SET PRICE.<br />

3. Single selection. Press the keypad<br />

numbers of the price you wish to use. As<br />

numbers are entered the numbers will shift<br />

in from the right as they are entered. Note:<br />

<strong>The</strong> CLR key will remove the last # of the<br />

price. Once the desired price is showing on<br />

the display press the selection desired for<br />

setting price. Press “” and display will<br />

show “PR $##.## B1 Selection Set”, press<br />

14

“” to set more prices or CLR to exit to SET<br />

PRICE.<br />

<strong>The</strong> last price entered for a selection is the one that<br />

is used. For example, If one price on the A tray was<br />

set to $1.50 using option 3 above and you wish to<br />

change the remaining selections on that tray using<br />

option 2, the pricing for the entire tray would take<br />

precedence. Conversely, if the price was set using<br />

option 2 first followed by the single selection using<br />

option 3, the pricing for the remainder of the shelf<br />

would remain and the new price for the single<br />

selection would change to the new value. Press the<br />

“CLR” key to return to “Set Prices”. Press the “CLR”<br />

key to return to “SERVICE MODE” or press the “A”<br />

key to advance to the next menu item below.<br />

SET SHELF LOCATION - Key “8”<br />

Allows the service technician to program the<br />

electronics to match the six different settings<br />

available for the shelves. <strong>The</strong>se settings are<br />

available to vend different package heights. <strong>The</strong><br />

factory default setting is Shelf Setting G. Press the<br />

number “8” on the keypad and display will show “Set<br />

Shelf Location”. Press the “” key and display will<br />

show current setting. To change the setting press<br />

one of the following: A = G setting, B = M1 setting, C<br />

= M2 setting, D = D setting, E = E setting, F = E1<br />

setting. Note G, M1, & M2 settings are used in<br />

venders prior to 0001-8487AE and D, E, & E1<br />

settings are used in venders 0001-8487AE & higher.<br />

Once the desired setting is showing on the display<br />

press the “” key to save the setting. Note: all shelf<br />

settings have to be physically set to match the<br />

programmed setting. You can not set the physical<br />

shelf settings differently. Press the “CLR” key to<br />

return to “Set Shelf Location”. Press the “CLR” key<br />

to return to “SERVICE MODE” or press the “A” key<br />

to advance to the next menu item below.<br />

RELAY TOGGLE - Press key “9”<br />

Allows the service technician to test the Light Relay,<br />

Fan Relay, and Compressor Relay. Press the<br />

number “9” on the keypad and the display will show<br />

“Relay Toggle”. Press the “” Key and display will<br />

show “Light A – On or Off”, “Fan B – On or Off”,<br />

“Compressor C – On or Off”. Display will show<br />

current status of the relay (not the component the<br />

relay operates). To toggle the state of a given relay<br />

press the letter key associated with it on the display.<br />

Caution: Disconnect power to the compressor before<br />

testing the compressor relay. Failure to disconnect<br />

power to the compressor before testing the relay<br />

could result in damaging the compressor. Press the<br />

“CLR” key to return to “Relay Toggle”. Press the<br />

“CLR” key to return to “SERVICE MODE” or press<br />

the “A” key to advance to the next menu item below.<br />

CLEAR ERRORS - Press key “0”<br />

Allows the service technician to clear errors<br />

recorded in the venders data. Press the number “0”<br />

Key and the display will show “CLEAR ERRORS”,<br />

then press “” Key and the display will show “Clear<br />

All Errors? = Y CLR = N”. Press the “CLR” key to<br />

return to “Clear Errors”. Press “” Key to clear all<br />

errors or press the “CLR” key to return to “SERVICE<br />

MODE”.<br />

TEST MODE<br />

Enter TEST MODE by opening the service door and<br />

pressing the blue Service button twice. <strong>The</strong> display<br />

will read” TEST MODE”.<br />

NEXT ITEM - Press key “A”<br />

LIST ERRORS - Press key “B”<br />

Allows the service technician to view a list of all<br />

recorded errors. Press the letter “B” on the keypad<br />

and the display will show “LIST ERRORS”, then<br />

change to “NONE” if no errors exist or, if errors are<br />

present, one of the error prompts below will be<br />

displayed. If an error code is displayed, press the<br />

“” key to view the next error until “END LIST” is<br />

displayed. With “END LIST” showing on the display,<br />

press the “” key to clear errors and return to TEST<br />

MODE. If you wish to exit the list without clearing<br />

errors, simply push the “CLR” key and the display<br />

will return to LIST ERRORS. If the CLR key is<br />

pressed prior to reaching the end of the list, the<br />

display will jump to END LIST. Explanations for the<br />

error codes are listed below. Note: <strong>The</strong> prompts<br />

listed will only show on the display if an error has<br />

occurred.<br />

NONE No errors have occurred.<br />

VEND MECH ERROR<br />

HORIZ – Horizontal Drive System problem.<br />

VERT – Vertical Drive System problem.<br />

PICKI – Picker not all the way in problem.<br />

PICKO – Picker out switch error problem.<br />

PORT – Port Drive System problem.<br />

VS – Vend Sensor problem.<br />

VMC ERRORS<br />

FRAM – Memory module read/write error.<br />

RTC – RTC read/write error, clock error.<br />

SF – Decimal error.<br />

RCRC – software not loaded properly.<br />

LB – Low battery.<br />

PWR OUT – Power lost.<br />

KEYPAD ERROR<br />

KEYPAD – Keypad not installed.<br />

COIN MECH ERROR<br />

CC – Coin Mech disconnected.<br />

TS – Tube Sensor defective.<br />

IC – No coin accepted for 96 hours (4 days).<br />

TJXX – Tube jam.<br />

CRCH – Check sum.<br />

15

EE – Excessive escrow pressed (255 times<br />

between coin arrivals).<br />

NJ – Coin jam.<br />

LA – Low acceptance count.<br />

DIS – Acceptor unplugged.<br />

ROUT – Coin routing error.<br />

NOTE ACCEPTOR ERROR<br />

BC – Note Acceptor disconnected.<br />

BFUL – Stacker full.<br />

BILL – Defective motor.<br />

BJ – Validator jammed.<br />

BRCH – ROM checksum error.<br />

BOPN – Stacker out of position.<br />

BS – Sensor problem.<br />

CARD READER ERROR<br />

CRC – Card reader disconnected.<br />

REFRIG ERROR<br />

SENS – Temperature sensor problem.<br />

COLD – Temperature to cold.<br />

HOT – Temperature to hot.<br />

CMPR – Compressor not cooling.<br />

HEALTH – Health Guard error.<br />

END LIST Indicates you have scrolled through the<br />

list of all present errors. Press the “CLR” key and<br />

display will change to “OK” and the display will<br />

change to “NONE”. Press the “CLR” key to return to<br />

“TEST MODE”, or the “A” key to proceed to “SELF<br />

TEST”<br />

LIGHT TIMER - Press key “C”<br />

Allows the service technician to set the 2 vertical<br />

lights to shut off for added energy savings after<br />

selected time recorded is met for no activity on the<br />

key pad or peripherals. Press the letter “C” on the<br />

key pad and display will show “Light Timer: ## hrs.”<br />

where ## is the current hour time recorded for<br />

meeting no activity to turn the two vertical lams off.<br />

To change the hour(s) setting press the key pad<br />

numbers that you wish to set for no activity to be met<br />

for the lamps to shut off. Press the “” key to save<br />

and the display will return to “Light Timer”. Press the<br />

“CLR” key to return to “TEST MODE”, or the “A” key<br />

to proceed to next available mode.<br />

** TEST MODE - Press key “D” (NOT<br />

USED AT THIS TIME)<br />

KEYPAD TEST - Press key “E”<br />

Allows the service technician to test any or all<br />

keypad keys. Press the letter “E” on the keypad and<br />

the display will show “KEYPAD TEST”. Press the<br />

“” key and the display will show “Keypad Test”,<br />

then press each key on the keypad. Each key<br />

pressed will show on the display until the “CLR” key<br />

is pressed. <strong>The</strong> display will return to “Keypad Test”.<br />

Press the “CLR” key to return to “TEST MODE” or<br />

press the “A” key to advance to the next menu item<br />

below.<br />

FACTORY DIAGNOSTICS - Press key “F”<br />

Allows the service technician to test the XY and Cup<br />

port operations. <strong>The</strong> following are available in the<br />

test menu: 1 = Position Test, 2 = Port Test, 3 =<br />

currently not used, 4 = Repeat Vend, 5 = Vend Error<br />

Codes, 6 = Use Port Sensor, 7 = Turns off vend<br />

mech for software test, 8 = Adjust shelf offset, 9 =<br />

Not used at this time, 0 – Adjust Hook Swipe. To<br />

enter the available modes press the “F” Key on the<br />

keypad and display will show “FACTORY<br />

DIAGNOSTICS”. Press the “” key and the display<br />

will show “1 = Position Test, 2 = Port Test”. Press<br />

the key # you wish to enter. Note: In early software<br />

revisions Port Test was 4, Repeat Test was 2, &<br />

Shelf Offset was 8. Below is current programming<br />

as of 12/21/07.<br />

1. Position Test. Note: <strong>The</strong> left or top door<br />

switch (depending on the mounting<br />

bracket in use) must be pulled to the out<br />

position to perform this test. Caution:<br />

XY needs to be in the home position<br />

before performing this test. If you<br />

look at the control board the green,<br />

amber (yellow), and red lights should be<br />

on at this time. If not please check the<br />

following: Green light is for home switch<br />

on bottom of port cup, amber light is for<br />

home switch on left side of Y motor<br />

assembly, red light is for home switch<br />

for picker cup plunger. Press the<br />

number 1 key and the display will show<br />

a set of numbers (ie ###### # ######<br />

#). To position test press the following:<br />

a. Shelf letter (A,B,C,D,E) to travel<br />

to selected shelf.<br />

b. Column number (1,2,3,4,5,6,7,8,<br />