MOLE ABRASIVI ERMOLI S.R.L.

MOLE ABRASIVI ERMOLI S.R.L.

MOLE ABRASIVI ERMOLI S.R.L.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MOLE</strong> <strong>ABRASIVI</strong> <strong>ERMOLI</strong> S.R.L.<br />

Sede ed uffici: Via Cairoli, 4 - 21046 - Malnate (VA)<br />

Tel. 0332-425114 - Fax 0332-426742 - info@ermoli.it - www.ermoli.it<br />

Stabilimento: Via Cairoli, 14 - 21046 Malnate (VA)<br />

Tel 0332-426088<br />

Codice Fiscale e Partita IVA IT 00210280129 - Registro Imprese VA 2386 - R.E.A. Varese 5558<br />

XA GRINDING WHEELS IN CUBITRON<br />

Our grinding wheels in microcrystalline Cubitron corundum make it possible to improve grinding<br />

performance significantly, especially on steels of over 55 HRC in hardness, and to work easily even on<br />

extremely hard steels.<br />

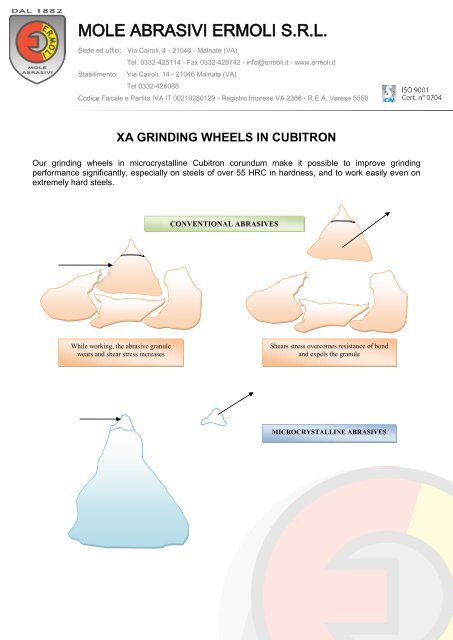

While working, the abrasive granule<br />

wears and shear stress increases<br />

CONVENTIONAL ABRASIVES<br />

Shears stress overcomes resistance of bond<br />

and expels the granule<br />

MICROCRYSTALLINE ABRASIVES

<strong>MOLE</strong> <strong>ABRASIVI</strong> <strong>ERMOLI</strong> S.R.L.<br />

Sede ed uffici: Via Cairoli, 4 - 21046 - Malnate (VA)<br />

Tel. 0332-425114 - Fax 0332-426742 - info@ermoli.it - www.ermoli.it<br />

Stabilimento: Via Cairoli, 14 - 21046 Malnate (VA)<br />

Tel 0332-426088<br />

Codice Fiscale e Partita IVA IT 00210280129 - Registro Imprese VA 2386 - R.E.A. Varese 5558<br />

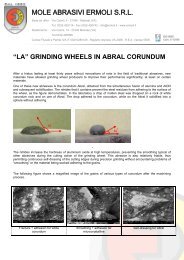

This is all possible thanks to the specific structure of these abrasives: traditional corundums wear or<br />

fracture in a macroscopic manner during grinding, thus reducing the duration of the wheel’s grinding<br />

properties, especially on hard materials.<br />

In contrast, each Cubitron granule consists of tiny crystals which during the action of the grinding wheel<br />

generate microscopic fractures, thus losing a minimal portion of abrasive but keeping shear stress and<br />

the resulting grinding wheel wear constant.<br />

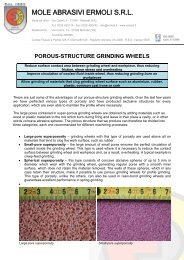

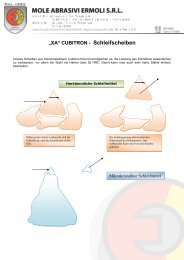

low-cost centre<br />

The negative aspect of Cubitron is its high cost: around 10<br />

times that of traditional abrasives. This means, for example,<br />

that the price of a grinding wheel with 30% microcrystalline is<br />

double. Therefore we have designed grinding wheels with a<br />

low-cost centre in which the part which is not used and<br />

manufactured with traditional corundum.<br />

Although the cost of the grinding wheel remains relatively high, we are able to optimise the performanceto-cost<br />

ratio by using the absolute minimum percentages of microcrystalline for the work to be done.<br />

In practical terms, the advantages of these grinding wheels are:<br />

increased grinding performance<br />

reduced grinding wheel wear, as it is dressed less often<br />

absence of burns, with colder cutting.<br />

The most common concentrations, depending of the type of use, are given in the table.<br />

code<br />

13XA<br />

23XA<br />

33XA<br />

53XA<br />

% Cubitron<br />

Depending of the machining to be performed, we vary the other abrasives contained in the mix to<br />

guarantee maximum performance.<br />

10%<br />

20%<br />

30%<br />

50%