Abstract

Stropharia rugosoannulata is a well-renowned edible mushroom due to its nutritional and nutraceutical properties. This article focuses on the study of stipe cracking in S. rugosoannulata, a common issue in outdoor cultivation of this mushroom in South China. The findings reveal that the stipe cracks of S. rugosoannulata are primarily horizontal (transverse). Typically, cracks appear between the annulus and the middle part of the stipe prior to the opening of the pileus. Following the opening of the pileus, a fresh crack appears on the upper part of the stipe above the annulus. During the growth of S. rugosoannulata, two distinct elongation sections are observed in the stipe, separated by the annulus. The location of cracks coincides with these elongation sections, and the sequence of crack occurrences matches with the sequence of these elongation sections. The frequency of stipe cracking varies according to developmental stages and humidity conditions. The conclusion of this study is that S. rugosoannulata stipes crack during elongation and within elongation sections when humidity is low (≤ 60%), with the S3 developmental stage having the highest risk of cracking.

Similar content being viewed by others

Introduction

Stropharia rugosoannulata, also known as Wine-cap mushroom or Roundhead mushroom, has a robust fruiting body. When mature, the stipe grows to a length of 9–15 cm and generates a deeply grooved annulus (ring) after the pileus opens1.

S. rugosoannulata is not only a food source high in protein, low in fat, and rich in minerals, vitamins, and dietary fiber2, but also a high-quality raw material for extracting bioactive compounds such as polysaccharides, sterols, and flavor peptides3,4,5. Additionally, it efficiently degrades and transforms various types of agricultural and forestry waste during its growth process6, helping to eliminate environmental pollutants and improve soil fertility7,8,9. S. rugosoannulata only needs remarkably simple cultivation techniques, yet it results in high yields10. Due to its significant application value in many fields, including dietary nutrition improvement, functional food production, environmental pollution control, ecological agriculture development, agricultural and forestry waste utilization, and rural poverty alleviation, S. rugosoannulata is recommended for cultivation by the Food and Agriculture Organization of the United Nations11.

S. rugosoannulata was first domesticated and cultivated in Germany in 1969. Subsequently, it was introduced and cultivated in other European countries such as Poland, Czechoslovakia, Hungary, and the Netherlands. By 1983, it was introduced to the United States1, 10. China introduced a strain of S. rugosoannulata from overseas in 1992 and the cultivation of S. rugosoannulata began to spread ever since12. Since 2013, the cultivation of S. rugosoannulata has been vigorously promoted as a poverty-reducing project in various regions of China, leading to a rapid growth in cultivation area and production. In 2021, China’s yield of fresh S. rugosoannulata mushroom exceeded 210,000 tons, marking a 43% increase from the yield recorded in 201913, Simultaneously, the cultivation area expanded to over 4000 hectares14.

In South China, S. rugosoannulata is suitable for outdoor cultivation in winter. It can be cultivated from December to March of the following year15. In cultivation practices in Guangdong province, large-scale cracking of S. rugosoannulata stipes is often observed, which significantly compromises the integrity of mushroom appearance, thereby diminishing its quality and commercial value.

The cracking of mushroom pileus in response to low humidity is a common phenomenon1. Mushrooms with thick and long stipes, such as Boletus sp., Armillaria sp., Amanita sp., Pleurotus eryngii, and S. rugosoannulata, can also experience stipe cracking in the wild. However, there is limited research on the phenomenon of mushroom cracking, with only reported in Lentinula edodes (Shiitake mushroom) the induction of pileus cracking to form flower-like pileus16, while studies on stipe cracking have not been reported thus far.

This article aims to investigate the number and location of stipe cracks in S. rugosoannulata under different humidity conditions, and to correlate these observations with the elongation process of the stipe during different developmental stages. A diagrammatic model is developed to illustrate stipe cracking, and the mechanisms behind this phenomenon are explained. The article further provides specific humidity conditions that can be applied to the factory cultivation of S. rugosoannulata mushrooms.

Materials and methods

S. rugosoannulata

S. rugosoannulata involved in this research are identified by Professor Jun Duan from the South China Botanical Garden of the Chinese Academy of Sciences as fruiting bodies of the strain “Zhongke No. 1 Red Songrong”, which is a new variety of S. rugosoannulata bred through systematic selection by the South China Botanical Garden of the Chinese Academy of Sciences and preserved in the laboratory of this research institution. They were produced by the understory bed cultivation method and the cultivation substrate formulation consisted of 40% rice husk, 40% sawdust, and 20% shredded forest litter. Fallen leaves, with a thickness of approximately 5 to 10 cm, served as the casing layer. The spawn was sowed in early November 2022, and mushrooms were harvested from mid-December 2022 to late March 2023. All methods were carried out in accordance with relevant guidelines.

The growth and development process of S. rugosoannulata mushroom can be divided into 5 stages in chronological order17. In Stage 1 (S1, young stage), the mushroom has a short and stout stipe. In Stage 2 (S2, early elongating stage), the stipe begins to elongate. In Stage 3 (S3, mid elongating stage), the stipe significantly elongates, but the pileus remains unopen, and no ring structure is visible. In Stage 4 (S4, half-open stage), the pileus starts to open, with the lower edge detaching from the stipe, but it is not fully expanded, taking on a roundhead shape. A ring appears, and the upper part of stipe is exposed. In Stage 5 (S5, fully open stage), the stipe grows to its maximum length and finishes its elongation, and the pileus extends horizontally to the top, releasing spores (Fig. 1).

Morphology of S. rugosoannulata mushrooms in different developmental stages (red arrows point to the annulus, yellow arrows point to the pileus, white arrows point to the stipe below the annulus, green arrows point to the upper part of stipe above the annulus). S1: young stage; S2: early elongating stage; S3: mid elongating stage; S4: half-open stage; S5: fully open stage.

Measurement of stipe cracks in S. rugosoannulata

Samples of S. rugosoannulata mushrooms of all developmental stages with consistent morphology were harvested, with a minimum sample size of 30 individuals per stage. The length of stipes and the location of cracks (the distance from cracks to the base of stipes) were measured. The stipe cracking rate (= number of stipes with cracks / number of stipes × 100%) of each stage were calculated and the maximum number of cracks on each individual stipe were counted. Additionally, relative humidity (RH) and air temperature at the time of harvest were recorded.

Measurement of stipe elongation in S. rugosoannulata

After the young mushrooms emerged on the surface of the cultivation substrate, they were transferred, along with the base substrate, into pots. These pots were then placed indoors, providing a controlled environment with 24 °C and 70% RH, in order to maintain the normal growth of young mushrooms. When the stipe length reached 2.5–3 cm, five young mushrooms with similar growth status were selected to measure the elongation of their stipes using the line-marking method. The initial mushroom pileus (covering the top of stipe internally) was marked as 0, and the initial stipe below the mushroom pileus was divided into 4 equal segments. Horizontal lines were drawn on the stipe using a marker pen, marking them as 1, 2, 3, and 4 from top to bottom. The length of each segment was recorded daily at 10:00 AM for a total of 4 days.

Measurement of elongation and cracking of the stipes of postharvest S. rugosoannulata

Five postharvest S. rugosoannulata mushrooms (S2) with consistent growth status were selected. They were placed indoors at 24 °C and three different levels of RH (40%, 60%, 70%). The elongation and cracking of the mushrooms were recorded. The overall length of each mushroom was measured daily at 10:00 AM for a total of 4 days.

Effects of casing layer on the cracking of S. rugosoannulata stipes

A cultivation plot with dense mushroom growth was selected and divided into two equal halves. The casing layer of one half was removed, exposing the stipes of S. rugosoannulata mushrooms completely to the air. In the other half, the thickness of the casing layer was increased to 15 cm, burying the mushrooms completely within the casing layer. On both of the aforementioned plots, ten individuals in consistent growth status from various developmental stages were selected, and the cracking of stipes was recorded one day after. The experiment was conducted separately on three different dates at RH of 40%, 55%, and 70%. The cracking rate of S. rugosoannulata stipes in different developmental stages was calculated, and the RH inside the casing layer was recorded.

Statistical analysis

Statistical analyses were performed using Excel 2013. Data with repeats were presented as the mean ± standard deviation. The illustration diagram of stipe cracks and elongation process were created by Microsoft Office 2013.

Results

Morphology of cracks on S. rugosoannulata stipes

During the development of S. rugosoannulata mushrooms, it is common for stipes to experience cracking (Fig. 2). The main type of cracks observed on the stipes of S. rugosoannulata is horizontal (transverse). Some horizontal cracks can encircle the stipe, forming circular cracks (Fig. 2c,d), while others may only occur on one side of the stipe (Fig. 2a,b). In certain cases, transverse cracks on the mushroom stipes may give rise to multiple longitudinal cracked pieces that outwardly curl. These segments are arranged in a radial pattern with two distinct levels (Fig. 2e–g). Some stipes may exhibit two parallel cracks at different heights (Fig. 2d). In other cases, new cracks may occur within an existing crack, resulting in overlapping positions of the two cracks (Fig. 2f). The outer layer of the cracked portion of the stipe appears harder and darker in color, while the interior of the cracks and the uncracked portions have a softer texture and a lighter color (Fig. 2f).

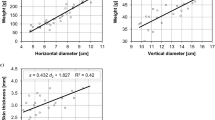

Location and number of cracks on S. rugosoannulata stipes

The location where cracks occur on the stipe of S. rugosoannulata mushrooms is typically on the portion of the stipe that extends beyond the casing layer and exposes to the air (Fig. 2). At the unopen stages, the cracks typically occur in the upper-middle portion of the stipe below the annulus. The distance from the crack to the base of the stipe ranges from 3.0 to 9.0 cm. The maximum number of cracks is two, and they are parallel with a distance of approximately 1.0 to 2.0 cm (Fig. 3). At the open stages, there may also be one crack on the upper part of stipe, approximately 0.5 to 1.5 cm above the annulus (Fig. 4). The number of transverse cracks on an individual stipe range from one to two.

Cracks on S. rugosoannulata stipes in different developmental stages

During the development process of S. rugosoannulata, the stipes elongated by nearly 9 cm (Table 1). In S1, no cracks were observed on the stipes. However, in the stages from S2 to S5, cracks occurred on the stipes. In S2, the maximum number of cracks observed was one. In S3, the number of cracks could increase by one, with a maximum of two cracks. These cracks were located below the annulus. The occurrence of cracks on the stipes in S4 was similar to S3. In S5, the stipe may crack once above the annulus, but only on stipes that have experienced a maximum of 1 crack below the annulus. In S4 and S5, the maximum number of cracks observed on a stipe was two (Fig. 5, Table 1).

The cracking characteristics of S. rugosoannulata stipes are summarized as follows: Stipe cracking was observed to start from S2, but the cracking rate was lowest in this stage. As the stipes elongated, the cracking rate increased, reaching its maximum in S5. After S5, the cracking rate remained stable. There was a significant increase in the cracking rate during the transitions from S2 to S3 and from S4 to S5, and the increase during S2 to S3 transition was greater. Among all the stages, S3 had the highest likelihood of stipe cracking (Fig. 6). Meanwhile, S3 is also the optimal harvesting stage for S. rugosoannulata mushrooms as they approach commercial maturity in this stage17. This indicates that stipe cracking has a significant destruction to the commercial value of mushrooms.

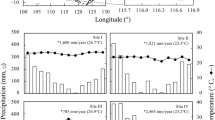

Environmental conditions influencing the cracking of S. rugosoannulata stipe

When RH of the cultivation field was ≤ 60%, cracks occurred on S. rugosoannulata stipes. When the RH dropped to around 20%, the cracking rate of the stipes reached nearly 100%. Conversely, when the RH of the cultivation field was ≥ 62%, cracks was not observed on S. rugosoannulata stipes (Fig. 6). RH of the cultivation field showed a negative correlation with the cracking rate of S. rugosoannulata stipes (Fig. 7a). Stipe cracking occurred in a temperature range of 11–23 °C, and there was no significant correlation between the cracking rate and temperature of the cultivation field (Fig. 7b).

Elongation process of S. rugosoannulata stipes

When cultivated at 24 °C and 70% RH, S. rugosoannulata stipes increased from an average height of 4.2 cm to 13.1 cm within a period of four days. And after the fourth day, the stipe no longer elongated (Fig. 8a). Each segment marked from 0 to 4 exhibited elongation, but the elongation of S. rugosoannulata stipe primarily occurred in the upper-middle portion of the stipe, especially in the portion covered by the pileus (segment 0) (Table 2).

When cultivated at 24 °C and 70% RH, the stipe inside the pileus experienced three instances of elongation over a period of three days, with daily increments of 2.3 cm, 1.3 cm, and 1.0 cm respectively. Three elongation sections were located at specific distances from the base of the stipe: 4.2–6.5 cm, 6.5–7.8 cm, and 10.0–11.0 cm. Elongation process of the stipe was divided into two periods based on the occurrence of the annulus (the opening of the pileus). Before the annulus appeared, the stipe underwent elongation below it, resulting in the formation of the first and second elongation sections. These two sections were connected, forming a continuous elongation section. After the annulus appeared, the stipe below the annulus stopped elongating, while the upper part of stipe above the annulus continued to elongate, resulting in the occurrence of another elongation section at the top of the stipe. The elongation section of the stipe after the pileus opening is separated from the elongation section before the pileus opening by the annulus, creating two independent elongation sections of the stipe (Fig. 8b).

By comparing the locations where S. rugosoannulata stipes cracked and elongated, it can be discovered that these two locations largely coincide with each other, both in specific section and in chronological order (Figs. 5 and 8b).

Elongation and cracking of postharvest S. rugosoannulata stipes

Postharvest S. rugosoannulata mushrooms were still capable of completing the growth and development process from S2 to S5 (Fig. 9), with the stipe undergoing a noticeable elongation of 3.2 cm. However, during the entire elongating process, the stipes did not exhibit any cracking when the RH was low (40–60%) (Table 3). This suggests that maintaining a connection between the stipe and the substrate was a necessary condition for stipes to crack.

Effect of casing layer on stipe cracking in S. rugosoannulata

After the casing layer was removed, S. rugosoannulata stipes were exposed to the air. When the RH was 40% and 55%, mushrooms in the initial stages of S1, S2, S3 and S4 exhibited stipe cracking after one day of growth, while mushrooms in the initial stage of S5 did not show any stipe cracking. Conversely, when a thicker casing layer completely covered all the mushrooms, RH inside the casing layer increased to a range of 63% to 75%, significantly higher than the RH outside. In this situation, none of the S. rugosoannulata stipes experienced any cracking (Table 4). These results indicated that S. rugosoannulata stipe only cracks in the elongation stages, particularly when the RH is low. Once the elongation stopped, the stipe no longer cracks. Casing layer effectively increases the environmental humidity and prevents stipe cracking of S. rugosoannulata.

In summary, S. rugosoannulata stipe is probable to crack (mainly in the form of horizontal cracks) during the process of elongation when environmental RH is ≤ 60%. There are three locations where the stipe cracks: two are located in the upper-middle part of stipe below the annulus, and one is located in the upper part of stipe above the annulus. These cracking locations generally coincide with the elongation section of the stipe. Before the pileus opens, the stipe below the annulus elongates, and there may be one to two instances of cracking in the elongation section. After the pileus opens, the stipe below the annulus stops elongating, while the stipe above the annulus continues to elongate, and there may be one instance of cracking in the elongation section. Stipes that have experienced cracking twice below the annulus do not crack again above the annulus. Once the stipe has stopped elongating, no further cracking occurs, and postharvest S. rugosoannulata stipes do not exhibit any cracking. Increasing environmental humidity can effectively prevent stipe cracking. The diagram illustrating stipe cracking of S. rugosoannulata is shown in Fig. 10.

Discussion

The mechanism of stipe cracking in S. rugosoannulata

Turgor pressure is the pressure exerted by water-filled vacuoles against the cell wall, resulting in an outward force on the cell wall. Turgor pressure creates mechanical stress within the cell wall18. Mushroom maintains turgor pressure by absorbing water from the substrate through mycelium, which is one of the driving forces for stipe elongation. When mushroom cells absorb water, the turgor pressure increases19. In low RH (≤ 60%) environments, on one hand, the outer layer of the stipe undergoes dehydration and shrinks, becoming dry and rigid, probably forming micro-cracks20. On the other hand, as turgor pressure increases within the stipe, the stress exerted on the outer layer of the stipe also increases, causing the micro-cracks to widen and eventually develop into visibly noticeable cracks. The reason for the occurrence of two parallel cracks on the stipe may be related to the turgor pressure changing in the form of pulses during mycelial growth21. After being harvested, S. rugosoannulata no longer receives water supply from substrate, resulting in a decrease in turgor pressure within the stipe. As a result, cracking does not occur during the elongation process. Therefore, the external cause contributing to stipe cracking in S. rugosoannulata is mainly the low-humidity environment, while the internal cause is primarily the turgor pressure within the stipe.

Less cracks in reality than in theory

According to the model in Fig. 10, a fully developed stipe of S. rugosoannulata has three potential cracking locations. Theoretically, all three locations may crack, resulting in a maximum of three cracks. However, the results of this study indicate that on a single stipe, it is unlikely to observe horizontal cracks in all three potential cracking locations. Out of the three possible cracking locaitons, a maximum of two locations may exhibit cracking simultaneously, with a maximum of two instances of cracking occurring. Stipes that have experienced two instances of cracking below the annulus will not experience further cracking above the annulus. The most common occurrence is a single instance of cracking in one specific location of stipe below the annulus. The reason for the actual number of stipe cracking being lower than the theoretical number may be related to the release of turgor pressure within the stipe after the previous cracking occurs22. If the stipe has already experienced two instances of cracking, most of the turgor pressure within the stipe will be released, and the remaining pressure will not be sufficient to cause further cracking on the stipe.

Lack of humidity management leading to stipe cracking in S. rugosoannulata

In South China, traditional outdoor cultivation is still the major way to produce S. rugosoannulata mushroom. This way of cultivation cannot avoid the limitations in humidity management due to less sophisticated infrastructure and environmental control, unlike the way of factory cultivation in which humidity can often be precisely controlled through advanced instruments11. This research proves again that humidity management is essential in the production of high-quality mushrooms.

To meet the temperature requirements (10–25 °C) for the growth and development of S. rugosoannulata, the cultivation seasons for most regions outside Guangdong are primarily spring and autumn. These seasons typically have higher rainfall23. In contrast, S. rugosoannulata is cultivated in Guangdong during the winter, which experiences less rainfall24. Taking Guangzhou as an example, the outdoor cultivation of S. rugosoannulata in Guangzhou occurs from December to March, which is the period with the lowest rainfall in the year. The monthly rainfall during this time is generally below 100 mm, with December and January experiencing less than 30 mm of rainfall. This period is characterized by a winter drought that occurs consistently throughout the year25,26,27. Dry environment is an external cause that contributes to stipe cracking in S. rugosoannulata. In regions outside of Guangdong, the cultivation seasons for S. rugosoannulata typically have a relatively humid environment, which seldom reaches the low level of humidity required for stipe cracking to occur. As a result, the phenomenon of stipe cracking may be less common in these regions. However, the entire cultivation season of S. rugosoannulata in Guangdong meets a dry and low rainfall climate. This leads to the widespread occurrence of stipe cracking in this region.

Data availability

The authors confirm that all data generated or analysed during this study are included in this published article.

References

Stamets, P. & Chilton, J. S. The Mushroom Cultivator: A Practical Guide to Growing Mushrooms at Home. http://library.uniteddiversity.coop/Permaculture/Mushroom Cultivator-A Practical Guide to Growing Mushrooms at Home.pdf. (1983).

Jing, B.-N. et al. Analysis and evaluation of nutrient components, bioactive substances and heavy metal content of Stropharia rugosoannulata in Bo’ai County. Sci. Technol. Food Ind. 43(4), 278–285. https://doi.org/10.13386/j.issn1002-0306.2021050090 (2022).

Li, X.-X. et al. Three-phase extraction of polysaccharide from Stropharia rugosoannulata: Process optimization, structural characterization and bioactivities. Front. Immunol. 13, 994706. https://doi.org/10.3389/fimmu.2022.994706 (2023).

Wu, J. et al. Isolation of bioactive steroids from the Stropharia rugosoannulata mushroom and absolute configuration of strophasterol. Biosci. Biotechnol. Biochem. 77(8), 1779–1781 (2013).

Chen, W.-C. et al. Characterization of novel umami-active peptides from Stropharia rugoso-annulata mushroom and in silico study on action mechanism. J. Food Compos. Anal. 110, 104530 (2022).

Kamra, D. N. & Zadražil, F. Influence of oxygen and carbon dioxide on lignin degradation in solid state fermentation of wheat straw with Stropharia rugosoannulata. Biotechnol. Lett. 7(5), 335–340 (1985).

Castellet-rovira, F. et al. Stropharia rugosoannulata and Gymnopilus luteofolius: Promising fungal species for pharmaceutical biodegradation in contaminated water. J. Environ. Manag. 207, 396–404 (2017).

Pozdnyakova, N. et al. The degradative activity and adaptation potential of the litter-decomposing fungus Stropharia rugosoannulata. World J. Microbiol. Biotechnol. 34(9), 133 (2018).

Gong, S. et al. Effects of wine-cap Stropharia cultivation on soil nutrients and bacterial communities in forestlands of northern China. Peerj 6, e5741 (2018).

Szudyga, K. Stropharia rugoso-annulata: The Biology and Cultivation of Edible Mushrooms 559–571 (Elsevier, 1978).

Marshall, E. & Nair, N. G. Make money by growing mushrooms (Food and Agriculture Organization of the United Nations, 2009).

Luo, Q. et al. Biological basis and bioactive components of Stropharia rugosoannulata and its application. Microbiol. China 50(6), 2709–2720. https://doi.org/10.13344/j.microbiol.china.220790 (2022).

China Edible Fungi Association. Statistical survey of edible fungi in China in 2021. Edible Fungi China 42(01), 118–127. https://doi.org/10.13629/j.cnki.53-1054.2023.01.021 (2023).

Xiong, W.-Q. et al. Cultivation status and development recommendations of Stropharia rugosoannulata. Edible Fungi 43(5), 73–75 (2021).

Ma, L.-F. et al. Effects of different Stropharia rugosoannulata culture medium on growth, yield and quality. North. Hortic. 22, 130–135 (2021).

Wang, C.-C. et al. Study on the grade evaluation method based on the pileus characteristics offlower Lentinula edodes mushroom and suitable environmental conditions for its formation. Edible Med. Mushrooms 31(2), 102–108 (2023).

Chen, R.-R. et al. Nutrients, texture and taste characteristics of Stropharia rugosoannulata during growth and development. Acta Edulis Fungi 29(4), 42–54. https://doi.org/10.16488/j.cnki.1005-9873.2022.04.006 (2022).

Ortega, J. K. E. Theoretical analyses of turgor pressure during stress relaxation and water uptake, and after changes in expansive growth rate when water uptake is normal and reduced. Plants 12(9), 1891 (2023).

Kamada, T. Stipe Elongation in Fruit Bodies 367–379 (Springer Berlin Heidelberg, 1994).

Benzahar, H. H. et al. Influence of Micro-Crack on the Propagation of a Semi-Infinite Crack (Authorea Inc, 2020).

Johns, S. et al. Pulses in turgor pressure and water potential: Resolving the mechanics of hyphal growth. Microbiol. Res. 154(3), 225–231 (1999).

Galstyan, A. & Hay, A. Snap, crack and pop of explosive fruit. Curr. Opin. Genet. Dev. 51, 31–36 (2018).

Yao, S.-B. et al. Seasonality of precipitation over China. Chin. J. Atmos. Sci. 41(6), 1191–1203 (2017).

Guo, J. Dynamic Monitoring and Quantitative Evaluation of Drought in Guangdon, China (Nanjing University of Information Science & Technology, 2008).

Guangzhou Meteorological Bureau. Guangzhou Climate Bulletin, 2020 (2021).

Guangzhou Meteorological Bureau. Guangzhou Climate Bulletin, 2021 (2022).

Guangzhou Meteorological Bureau. Guangzhou Climate Bulletin, 2022 (2023).

Funding

The funding was provided by Guangzhou Municipal Science and Technology Project (Grant No. 2023B03J0781), 2022 Guangdong provincial rural revitalization strategy special funds for breeding industry revitalization project (Grant No. 2022-WPY-00-002), Heyuan Municipal Science and Technology Project (Grant No. 220706111471518).

Author information

Authors and Affiliations

Contributions

L.H. Conceptualization, Writing—Original Draft, C.S. Methodology, Investigation. H.S. Software and Visualization. C.H. Supervision. J.D. Funding acquisition. Writing—review and editing. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, L., Si, C., Shi, H. et al. Research on the stipe cracking of wine-cap mushroom (Stropharia rugosoannulata) in different humidity conditions. Sci Rep 13, 21122 (2023). https://doi.org/10.1038/s41598-023-48608-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-48608-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.