What is Peelable Solder Mask?

What is Peelable Solder Mask?

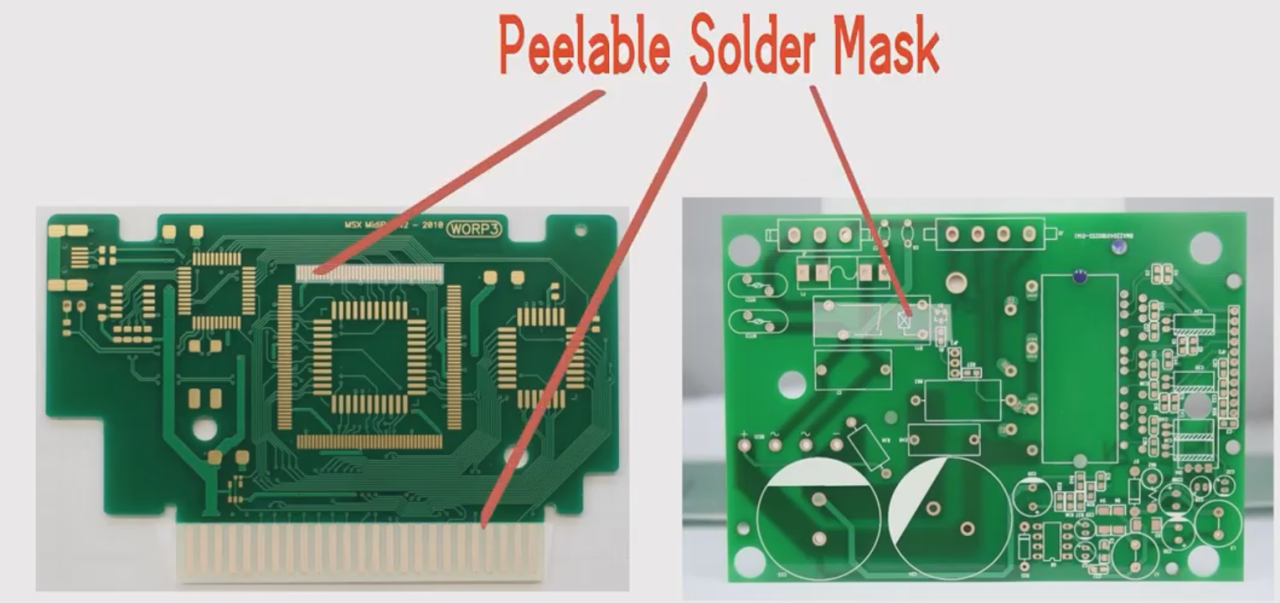

A peelable solder mask is a type of solder mask that can be peeled off the surface of a printed circuit board. This type of solder mask is used to protect specific areas of the PCB during reflow, wave soldering or surface finish process. It is applied on pads or plated through holes prior to the PCB assembly process and prevents excess solder buildup on empty pads during the soldering process. It also protects gold-plated contacts that can dissolve in molten solder. Peelable solder mask is easier to remove than normal solder mask.

Peelable solder mask is also used in selective surface treatment processes such as soft gold PCB finish or hard gold PCB finish. This type of solder mask ensures that the correct surface finish is applied only to the desired areas of the PCB. Finishes are coatings on bare copper areas of a PCB to provide a solderable surface and protect exposed copper circuits.

Peelable solder mask is also required for parts that will be installed manually after the automated assembly process.

Peelable solder mask is usually screen printed and removed after processing at a contracted PCB assembly facility. PCB manufacturers can apply masks of any design or shape on one or more sections on each side at a time.

PCB often require protection of selected circuit board areas during surface preparation or assembly to prevent solder flow onto contacts, terminals, and plated through holes (PTHs). In the past, hearing resistant tape was applied manually in various shapes and sizes, resulting in production delays, time costs, and more time and cost to remove the tape.

Peelable solder mask provides protection for PCB during soldering processes such as wave soldering, reflow, or surface finish protection at the PCB level. Multi-surface finishes such as carbon ink, hard gold or bondable gold require protection against a balance of finishes such as ENIG or Immersion Silver. Peelable masking is a reliable, time-saving and cost-effective process that has long surpassed manual masking with heat-resistant tapes.

General Features and Benefits of Peelable Solder Mask

- Time and cost saving process compared to tape.

Taping is a non-mechanical process involving people. Depending on the volume involved, it may take several people hours or days to complete the recording process. The tape cannot be modified to mask the desired area, which usually adds more labor costs.

- Protect complex structures and shapes with efficient screen printing.

Many areas on a PCB may need to be protected from the assembly process, and on different surface areas of different shaped parts. Use Gerber files to create layers to protect, make the screen in one operation and allow masking to be applied in one scan, easily protecting all areas.

There are several steps to assembly - larger features can be covered and holes up to 0.120 diameter can be easily managed. This protective face shield prevents splashes from nearby sensitive features that do not require assembly. Removing the mask later in the process allows you to manually assemble or mechanically handle the balance of the part.

Peelable masks are easily removed by lifting at a section of the mask off the surface and slowly pulling away from the lifted part. The mask leaves no residue or particles and no additional cleaning is required. Unlike the old tape application, alcohol is usually used to remove the remaining stickiness from the tape.

- Contamination-free, contamination-free and non-corrosive are three key elements for a successful PCB assembly process.

- RoHS compliant and can be used on all finishes and remains fully compliant and certified. It is 550°F (288°C) stable, phthalate free, low toxicity and environmentally safe.

It is compatible with rosin, no-clean and water-soluble flux types for ease of manufacture at the assembly level. This underutilized process should be reviewed to ensure its flexible protection of critical areas of the PCBs.

If you need peelable solder mask on your PCBs, feel free to contact us for further discussion jessie@ucreatepcb.com. whatspp/wechat:+8613507459210.