Developing active chitosan-based edible film for extending the shelf life of guacamole

- 1Facultad de Ciencias Químicas, Benemérita Universidad Autónoma de Puebla, Puebla, Mexico

- 2Instituto Politécnico Nacional, Centro de Investigación en Biotecnología Aplicada, Tepetitla de Lardizábal, Tlaxcala, Mexico

- 3Facultad de Ingeniería Química, Benemérita Universidad Autónoma de Puebla, Puebla, Mexico

This study aimed to evaluate the effect of edible films (EFs) on important parameters of fresh guacamole and to select the best EF for evaluating its stability and protection effect after 28 days of storage (at 4 and 20°C). EFs based on chitosan (2%), glycerol (1%), citric acid (1.5–2.5%), and lemon-onion extract (0–2%) were applied on the surface of fresh guacamole to evaluate its effect in its color and microbiological and antioxidant properties after 48 h of storage (at 4 and 20°C). Results indicated that EFs delay the total color change and increase the antioxidant capacity of guacamole, while the microbial count was less than 100 CFU/g and 10 CFU/g for mesophylls and molds plus yeasts, respectively. According to the lowest total color change (7.93–14.92) and highest antioxidant capacity (1201.22 mg Trolox/100 g), EF1 (2% chitosan, 1% glycerol, 1.5% citric acid, and 2% lemon-onion extract) was selected for its analysis during the storage. After 28 d of storage at 4 and 20°C, a slight change in the physical characteristics of the EF was observed, while microbial load and antioxidant properties remained constant. Moreover, the selected EF maintained its capacity to avoid guacamole browning, being well-accepted by consumers (I like - I like much) who did not detect the application of EF, even after 24 h of its application onto the fresh guacamole. Results presented in this study indicated that developed EF maintained the quality characteristics of guacamole, and its effect did not change after 28 d of storage.

1. Introduction

Nowadays, consumers are demanding food products with fresh-like characteristics, high sensory and nutritional quality, free of synthetic additives, ready-to-eat, clear labels, environmental packaging, and health-promoting compounds, such as antioxidants, antimicrobials, fiber, vitamins, pigments, and probiotics, and with beneficial effects on mental and physical performance (Hernández-Carranza et al., 2022). Additionally, the increased amount of food waste, environmental damage, natural resource consumption, and economic losses are factors that consumers are also taking into account (Morone et al., 2019). All these demands have been considered for formulating a sustainable reference diet developed by the EAT-Lancet Commission, aiming at reducing the incidence of mortality related to unhealthy diets and habits while improving food system sustainability (Hirvonen et al., 2020; Dalile et al., 2022).

Packaging has become an essential factor in the food industry because it is presented in the entire food processing chain. It fulfills four purposes: containment, protection, communication, and convenience (Siddiqui et al., 2022). Although conventional food packaging materials such as plastic, paper, glass, and metal, have been used, they have environmental and edible limitations. Among conventional packaging materials, plastic (polyethylene, polypropylene, and polyethylene terephthalate) is the most used due to its performance, versatility, barrier properties, lightweight, and convenience (Bhargava et al., 2020). However, plastic is not environmentally friendly, presenting a serious drawback (Kumar et al., 2022). Therefore, an increasing tendency for bioplastics or biopolymers made from renewable resources is on the rise (Sáez-Orviz et al., 2021; Chaudhary et al., 2022).

Edible films and coatings are materials of thickness less than 0.3 mm formulated from biopolymers and edible additives dispersed in aqueous media (Díaz-Montes and Castro-Muñoz, 2021). The main difference between edible films and coating is that the former is first pre-formed and then placed on the surface of a food product (Galus et al., 2020). They are commonly made by casting, molding, or extrusion techniques (Ribeiro et al., 2021). Contrary to the edible film, a coating is a thin layer of edible material formed on the surface of a food product (Bizymis and Tzia, 2022). Both edible film and coating act as protective materials that can be consumed with the food product. Among biopolymers, cellulose, starch, alginates, pectin, chitosan, wheat gluten, corn zein, gelatin, casein, and soybean are the most studied. Although edible film and coating provide a mechanical barrier against environmental injuries, they have also been tested as carriers of antioxidants, antimicrobials, beneficial microorganisms, aromas, additives, and pigments, among other compounds (Díaz-Montes and Castro-Muñoz, 2021; Bizymis and Tzia, 2022; Iversen et al., 2022; Kumar et al., 2022).

Avocado (Persea americana L.) is a native fruit from Mexico and Central America belonging to the Lauraceae family (Cid-Pérez et al., 2021). It is a climacteric fruit considered the most economically important tropical/subtropical crop globally (Martínez-Padilla et al., 2017), with a 6% increase in avocado production in the last decade (Muñoz-Redondo et al., 2022). Mexico is the largest avocado-producing country, having an average production of 1,529,922.25 tons between 2010 and 2017 (Kimaru et al., 2020). The increase in avocado consumption is owed to its pleasant flavor and nutritional and immune system-enhancing characteristics (Stephen and Radhakrishnan, 2022). In this sense, the edible part contains higher quantities of insoluble (70%) and soluble fibers (30%), monounsaturated fatty acids (oleic and palmitoleic acids), which reduce the blood levels of undesirable low-density lipoprotein and increase high-density lipoprotein, and health-promoting compounds such as vitamins (B, C, E), carotenoids, and folic acid (Araújo et al., 2018). Though several products (oil, paste, concentrates, powders, and frozen pieces) have been developed from avocado, it is mainly consumed in its fresh form. Guacamole is one of the favorite snacks enjoyed in the United States, mainly during the Super Bowl, comprising 49.4% of the deli-prepared dip/sauces category in grocery stores (Statista, 2019). However, the main problem of guacamole is its rapid enzymatic browning and susceptibility to oxidative reactions caused by its high-fat content (Rodríguez-Campos et al., 2022). In this sense, different natural and chemical additives and extracts have been evaluated to maintain the brilliant green color of fresh avocado pulp (Bustos et al., 2015; Ospina et al., 2018; Fuentes Campo et al., 2019; Magri et al., 2022; Rodríguez-Campos et al., 2022). However, according to the best of our knowledge, the evaluation of edible film on guacamole characteristics has not been studied yet. Therefore, this study aimed to develop an edible film to extend the shelf life of guacamole. To achieve this purpose, the following topics were covered: (i) formulate and evaluate EFs on maintaining the color, antioxidant capacity, and microbiological stability of avocado puree during storage, (ii) evaluate the effect of storage conditions on the physical, antioxidant capacity, and microbiological characteristics of selected EF, and (iii) evaluate the stability during storage of chosen EF on maintaining the quality characteristics of guacamole.

2. Materials and methods

2.1. Plant materials

Avocados (Persea americana L. cv. Hass), white onions (Allium cepa), and Persian lemons (Citrus × latifolia) were purchased from a local supermarket in Puebla, Puebla, Mexico. Fruit and vegetables were selected free from physical and microbiological appearance damage. Avocado and lemon were washed with tap water and gently dried using absorbent paper, while no edible parts of onions were removed.

2.2. Lemon and onion extracts

Lemon juice was obtained by manually squeezing halves of lemon. Juice (100 mL) was placed in Petri dishes (10 mL each) and dried (Excalibur, United States) at 40°C until constant weight (24 h approximately). Onions were cut into squares (1 cm2) using a stainless-steel knife, dried at 40°C for 24 h, ground, and sieved (450 μm). Both dried lemon juice and onions were immediately used to make the lemon-onion extract. The extract of lemon and onion was obtained according to the methodology proposed by Rodríguez-Campos et al. (2022). Briefly, the lemon extract was obtained by suspending dried lemon juice with distilled water in a ratio of 1:4 (w/v). An onion extract was obtained by placing 10 g of onion powder (450 μm) with 250 mL of distilled water for 1 h in a magnetic stirrer hot plate at 250 x g (Cimarec, SP-131325, USA). The extracts were cotton-filtered and mixed (1,4 v/v) for formulating EF films.

2.3. Guacamole obtaining

Peeled and pitted avocado halves were processed (Black and Decker, Mexico City, Mexico) until a puree was obtained. The puree was quickly mixed with table salt (1:100 w/w), taking care not to incorporate O2 into the mix, and immediately used for evaluating the EFs.

2.4. Solvents and reagents

All reagents and solvents used in this study were obtained from Sigma-Aldrich, Inc. (Toluca, Mexico). Broths and agars were obtained from BD Bioxon (Mexico City, Mexico).

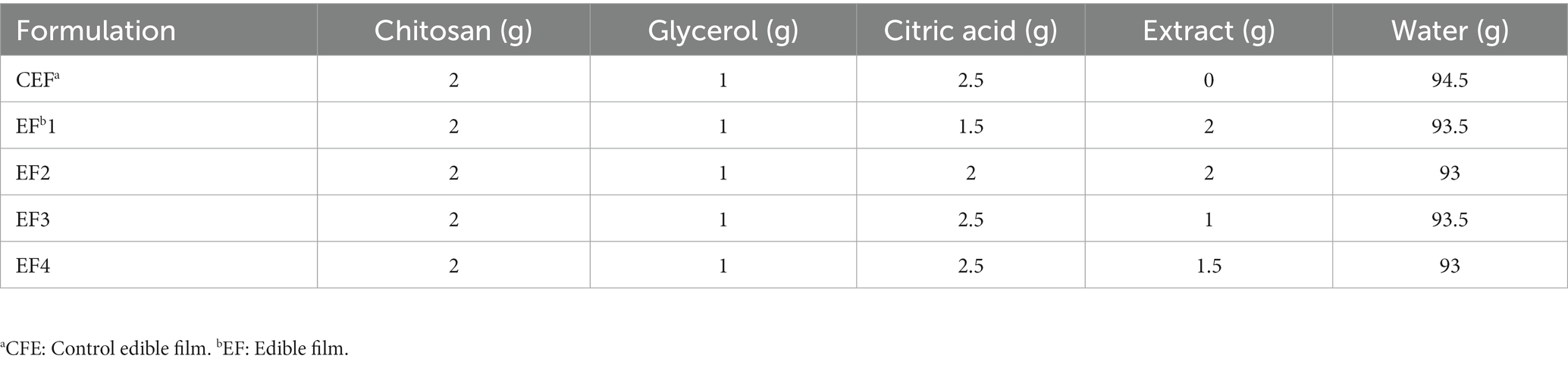

2.5. Edible films formulation

Filmogenic suspensions were prepared according to the data presented in Table 1 (formulations were selected according to preliminary studies). Briefly, 1 g of glycerol was mixed with a specific amount of citric acid, lemon-onion extract, and distilled water. Then, 2 g of low molecular weight chitosan was slowly added until all chitosan was solubilized. The mixture was left to stand for 2 h at 4°C to eliminate air bubbles. EFs were produced by casting methodology (Aparicio-Fernández et al., 2018). To produce EFs of 12 cm 8 cm, 96 mL of the filmogenic suspension (1 mL/cm2) was placed in wax paper, which was dried at 45°C until reaching a moisture of about 15% (wet basis). EFs were gently withdrawn from the papers and used for analysis.

2.6. Analysis of edible films and selecting edible film for storage evaluation

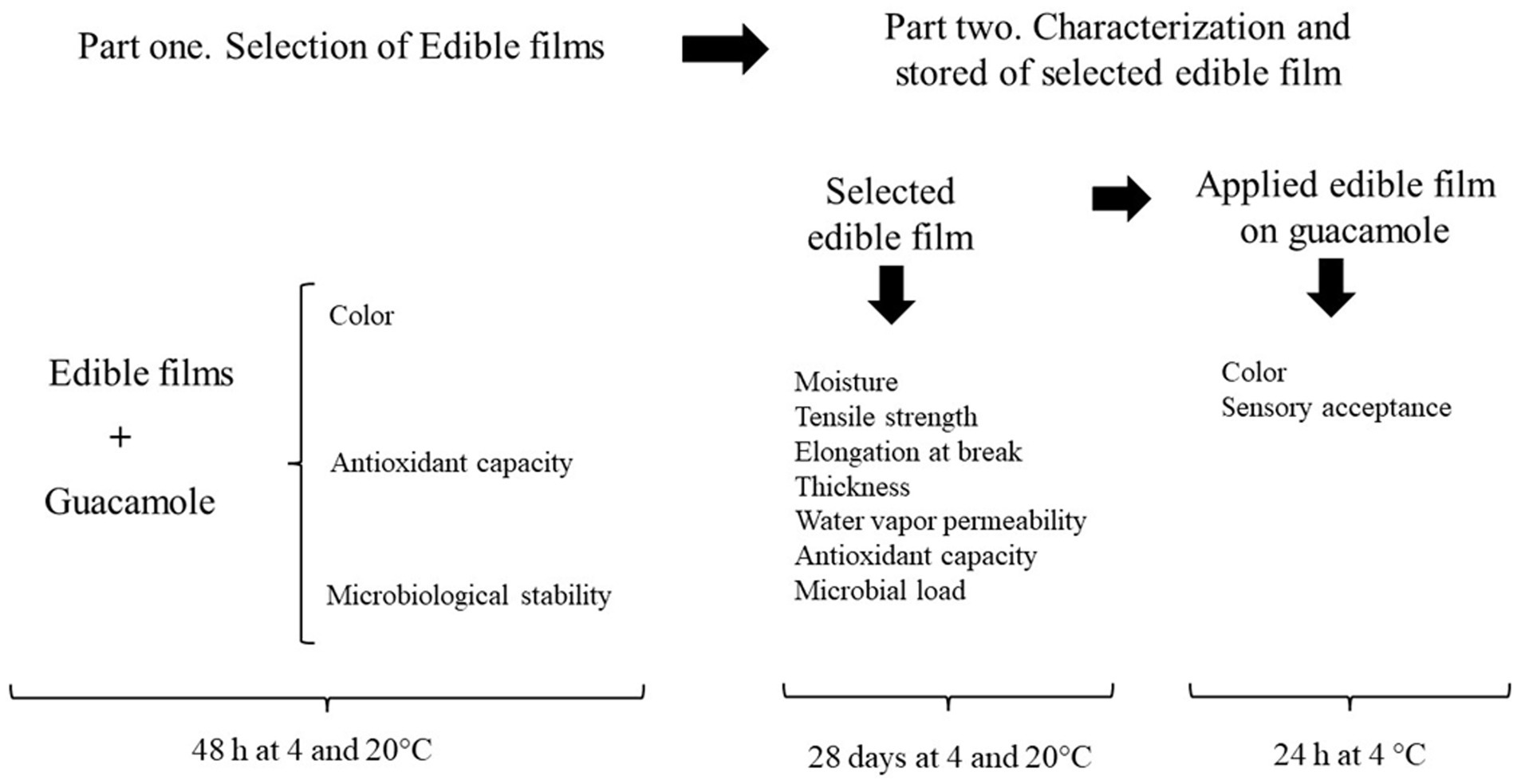

2.6.1. Part 1. Edible films evaluation

This study was carried out in two different steps (Figure 1). The first step was conducted to select the formulation that best maintains the quality characteristics (color, antioxidant capacity, and microbiological stability) of guacamole during 48 h of storage at 4 ± 1°C and 20 ± 2°C (room temperature).

Figure 1. Schematic representation of chitosan-based edible film for extending the shelf life of guacamole.

2.6.2. Part II. Effect of storage conditions on the quality characteristics of selected edible film

The second part of this study was performed to evaluate the effect of storage conditions (28 d at 4 ± 1°C, RH = 40 ± 2% and 20 ± 2°C, RH = 45 ± 5% using linear low-density polyethylene bags of 17.7 cm × 18.8 cm) on the quality characteristics of selected EF and to assay the capacity of EF for maintaining guacamole quality. The selected EF was characterized in its physical, microbial, and antioxidant properties and subsequently evaluated for its effect on color maintenance, antioxidant, microbial characteristics, and sensory acceptance of guacamole.

2.7. Moisture

Moisture was gravimetrically determined by oven-drying at 105°C until a constant weight was attained (5 h approximately).

2.8. Color

The color of EFs applied to the guacamole was measured using a colorimeter Reader (TCR 200, TIME High Technology, Beijing). The color was measured on the surface of the guacamole without mixing with the edible film. The luminosity (L*), + red to -green (a*), and + yellow to -blue (b*) color parameters were measured and used to calculate the Hue, Chroma, and total color change (∆E) using the following equations:

where , , and and , , and are the color parameters at the beginning and at the end of storage, respectively.

2.9. Physical characterization

The EF was evaluated in its thickness (Th), tensile strength (TS), and elongation at break (EAB). Th was determined by taking five random measurements using a millimeter micrometer (IP54, Qfun, China). TS and EAB were studied using a texture analyzer (EZ-test, EZ-SX, Shimadzu Corp., Japan). Film rectangles (3.5 cm 6.0 cm) were held tightly between mechanical grips at an initial distance of 3 cm. The force (N) and deformation (mm) were recorded during extension at 60 mm/min. Mechanical properties were determined using the interface software TRAPEZIUM X Material Testing Operation Software V 1.4.0. TS and EAB were calculated according to the ATM D882-95 method (ASTM, 1995).

2.10. Water barrier property

The water vapor permeability (WVP) of EF was gravimetrically measured using the ASTM E96-92 method (Cerqueira et al., 2012). The EF was sealed on the top of a vessel containing distilled water. The vessel was placed at 4 ± 1°C (40 ± 2% RH) and weighted at 2-h intervals for 10 h. Water vapor permeability was calculated with the following equation:

where WVTR is the water vapor transmission rate (g/h m2), L is the Th of EF (mm), and ∆P is the difference between partial water vapor pressure (kPa).

2.11. Edible film and guacamole extracts for antioxidant assays

One gram of EF was dissolved with 10 mL of distilled water using a magnetic stirrer hot plate. The extract was cotton-filtered and immediately used for antioxidant evaluation. On the other hand, for obtaining the avocado extract, 5 g of avocado puree (with or without EF) was mixed with 50 mL of absolute acetone using a stomacher (model 400, Seward, West Sussex, United Kingdom) at 300 x g for 3 min. The extract was centrifuged (Premiere XC-2450, TX, United States) at 3000 x g for 10 min. The supernatant was taken and dried until the solvent was evaporated. 1 g of dried extract was resuspended with 50 mL of distilled water and used for antioxidant determinations.

2.12. Total phenolic compounds

Total phenolic compounds were evaluated according to the methodology proposed by Hernández-Carranza et al. (2016). Briefly, 1 mL of extract was mixed with 1 mL of Folin-Ciocalteau reagent (0.1 N), and 3 min later, 1 mL of Na2CO3 (0.05% w/v) was added. After 30 min of incubation in a dark environment at room temperature, the absorbance was read at 765 nm using a UV–Vis spectrophotometer (model 6,405, Jenway, United Kingdom). The total phenolic compounds were quantified using a standard curve of gallic acid.

2.13. Antioxidant capacity

Antioxidant capacity was evaluated as the inhibition of the DPPH (2,2-diphenyl-1-picrylhydrazyl) radical following the methodology reported by Hernández-Carranza et al. (2016). Briefly, 1 mL of the extract was mixed with 1 mL of DPPH radical (0.004% w/v). The mixture was left to stand for 30 min in a dark environment at room temperature. After 30 min, the solution was read at 517 nm using a UV–Vis spectrophotometer. Results were expressed as mg equivalent of Trolox (Trolox/100 g) using a standard curve of Trolox.

2.14. Microbiological analysis

Mesophylls and molds plus yeasts were quantified in EF and avocado puree with or without EF. Briefly, 1 g of EF or a mixture of avocado puree plus EF was placed in a sterile bag with 9 mL of peptone water and collocated for 1 min in a stomacher equipment (300 x g). Then, 1 mL of the sample was serially diluted to reach an adequate count (30–300 CFU/g). Mesophylls and molds plus yeasts were plated in nutritive and potato dextrose agar, respectively. Mesophylls were incubated at 37 ± 2°C for 24 h, whereas molds plus yeasts were incubated at 22 ± 2°C for 72 h.

2.15. Consumer acceptance

Three hundred grams of guacamole were placed in a baker (12 cm length, 8 cm width, and 5 cm height), and the fresh or stored EF was collocated on the top of the guacamole, taking care of eliminating all air bubbles. Guacamole with applied EF was stored for 24 h at 4 ± 1°C and then mixed (EF is diluted in avocado puree) and used for consumer acceptance. Fresh avocado puree was used as a control and it was formulated using the same amount of citric acid, salt, and lemon-onion extract as the selected EF. Consumer acceptance was evaluated through a hedonic scale of 7 points, where 1 means dislike very much and 7 means like very much. A tortilla chip added with guacamole (at room temperature) was provided to 100 untrained judges who frequently consume avocado products. Aroma, color, texture, flavor, and overall acceptance of guacamole were evaluated at the beginning and after 28 days of storage of EF (storage at 4 ± 1 and 20 ± 2°C).

2.16. Statistical analysis

All results were analyzed by comparison of means (α = 0.05) through analysis of variance (ANOVA) using Tukey’s test of Minitab 15 software (Minitab Inc., State College, United States).

3. Results and discussion

3.1. Evaluation of edible films

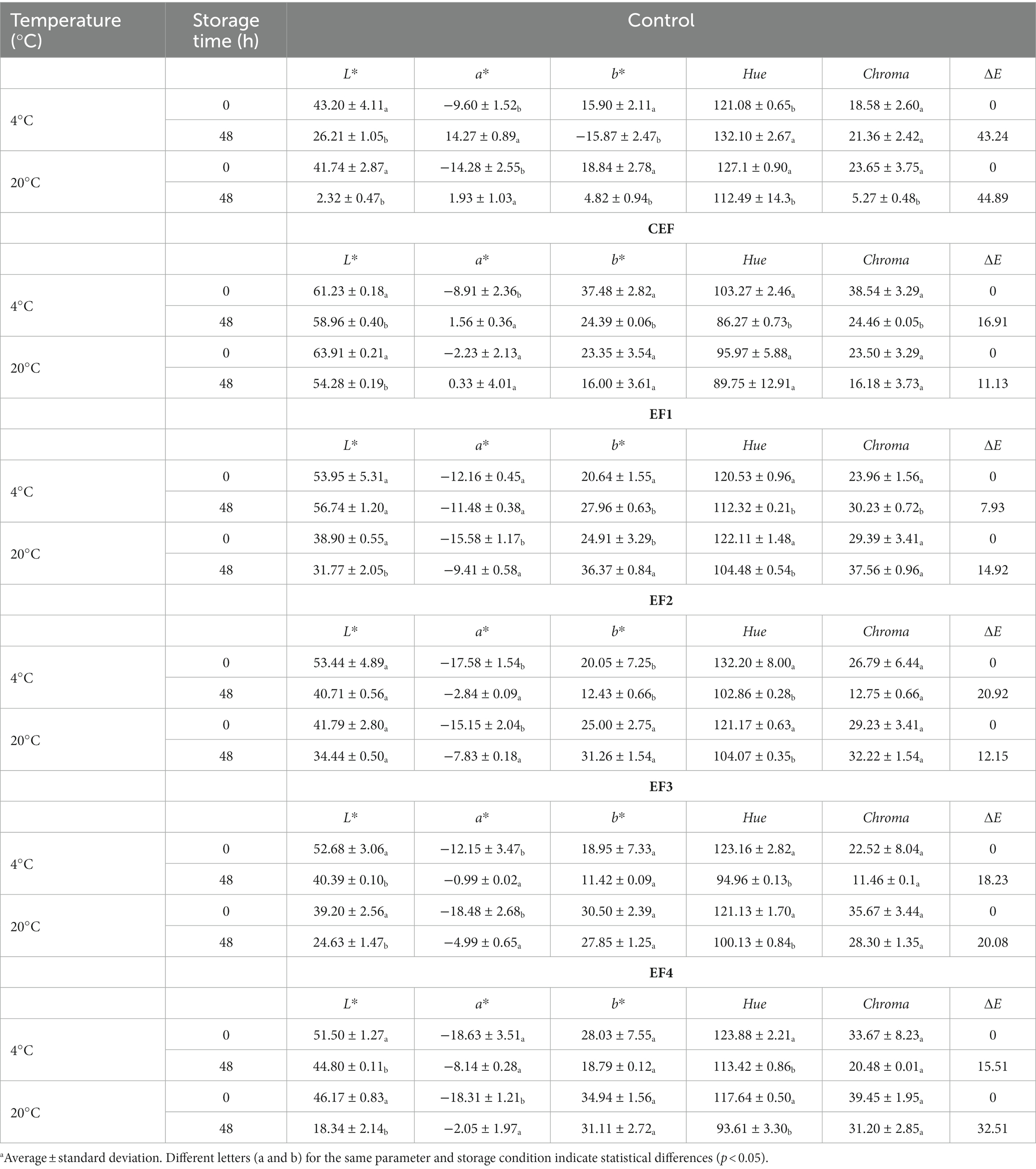

The effect of formulated EFs on the color parameters of guacamole stored for 48 h at 4 and 22°C is presented in Table 2. At the beginning of the storage, the values of L*, a*, and b* were in the range of 38.90 to 61.23, −18.63 to −2.23, and 15.90 to 37.48, respectively. These values were similar to those reported by Cortés-Rodríguez et al. (2019) for the same parameters (L* = 47.3 to 54.6, a* = −7.3 to −4.6, and b* = 31.76 to 36.1). After 48 h of storage, L* and b* color parameters decreased, while a* color parameter increased, which indicates a change of color from a medium dark shade of green to a shade of yellow-green– a medium dark shade of yellow-green at 4°C or even a dark shade of yellow-green – a very dark shade of yellow at 20°C when edible films were applied. As expected, the control guacamole presented the darkest color. Luminosity, the main indicator of enzymatic browning, did not change in guacamole with EF1 and EF2 at 4°C, which is important because it indicates the brightness of guacamole in terms of color (Salvador-Reyes and Paucar-Menacho, 2019). On the other hand, an overall effect of EF and storage time in a* and b* parameters might be analyzed through Hue and Chroma, which indicate the angle (0: red, 90° = yellow, 180° = green, and 270° = blue) and the color saturation or intensity (magnitude vector from L*), respectively. Regardless of the application of EF, Hue decreased on average from 119.10 to 106.99 or 107.76 at the beginning and after 48-h storage at 4 and 20°C, respectively, showing the storage temperature effect. On the other hand, in almost all cases the intensity of the color was reduced, indicating a duller color of the guacamole. As mentioned before, EF may protect food products from environmental effects such as oxygen, light, gas interchange, moisture loss, etc. In this sense, total color change indicates an effect of EF on guacamole, reducing the color change at less than 22.32 and 12.38 units when guacamole was stored at 4 and 20°C, respectively. It is important to point out that according to these results, EF1 showed less color change (7.93 and 14.92 at 4 and 20°C, respectively) after 48 h of storage. These values are low compared to those reported by Rodríguez-Campos et al. (2022), who informed total color change from 18.1 to 42.2 in avocado puree added with lemon and onion extract and stored for 7 days in hermetic-glass bottles at 4°C. Moreover, the results obtained in this study with EF1 at both temperatures were in the range (4.4–12.4) of those reported by Bustos et al. (2015). In their study, the authors formulated avocado puree with ascorbic acid (0.2 mg/g avocado), garlic (0.1 g/g avocado), onion (0.1 g/g avocado), or scallion (0.1 g/g avocado) and stored the puree in polyethylene bags at 4°C for 5 days. In the same study, guacamole with citric acid (pH = 4.0, specific amount was not informed by the authors) showed a value of 21.8 of color change (4°C for 5 days) compared to 28.3 of untreated avocado pulp. Therefore, even though citric acid may decrease color change in avocados, it is not the main compound responsible for preventing color change in guacamole.

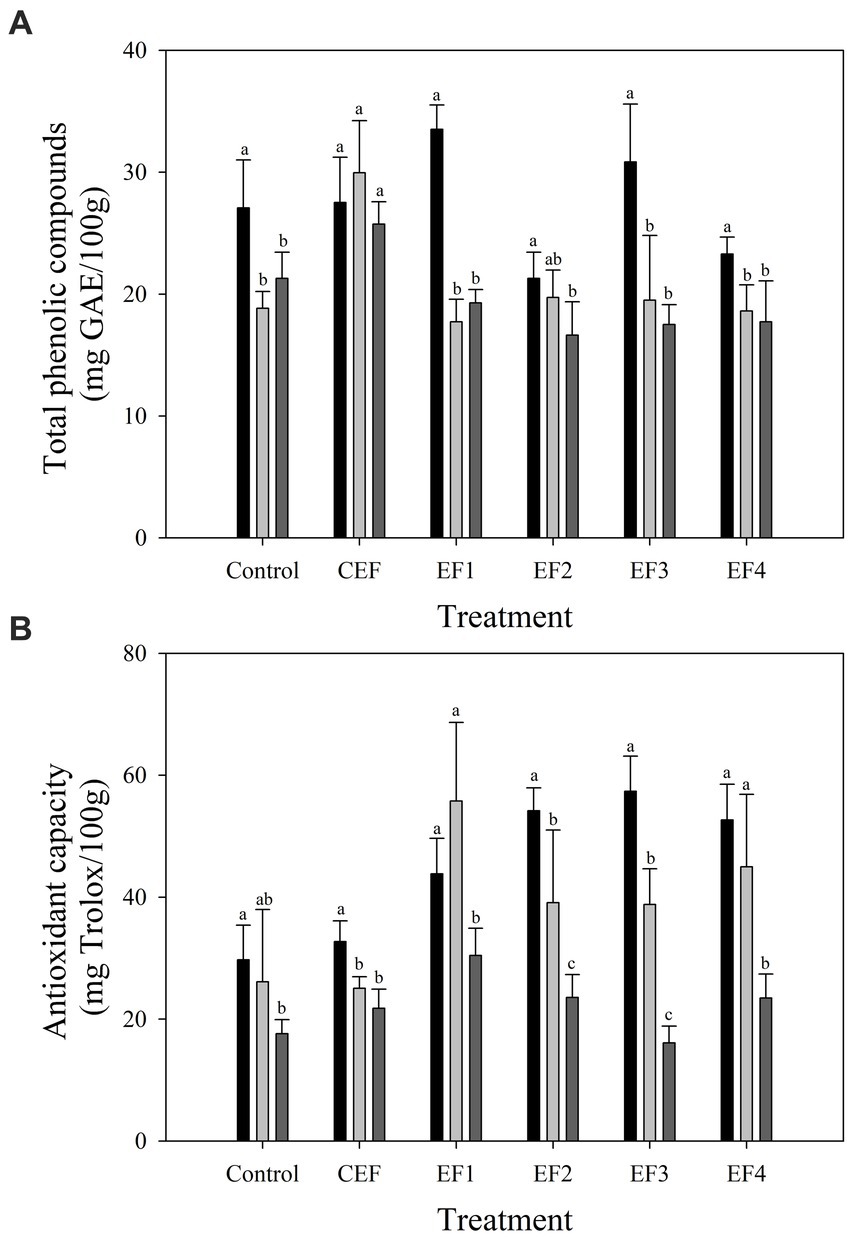

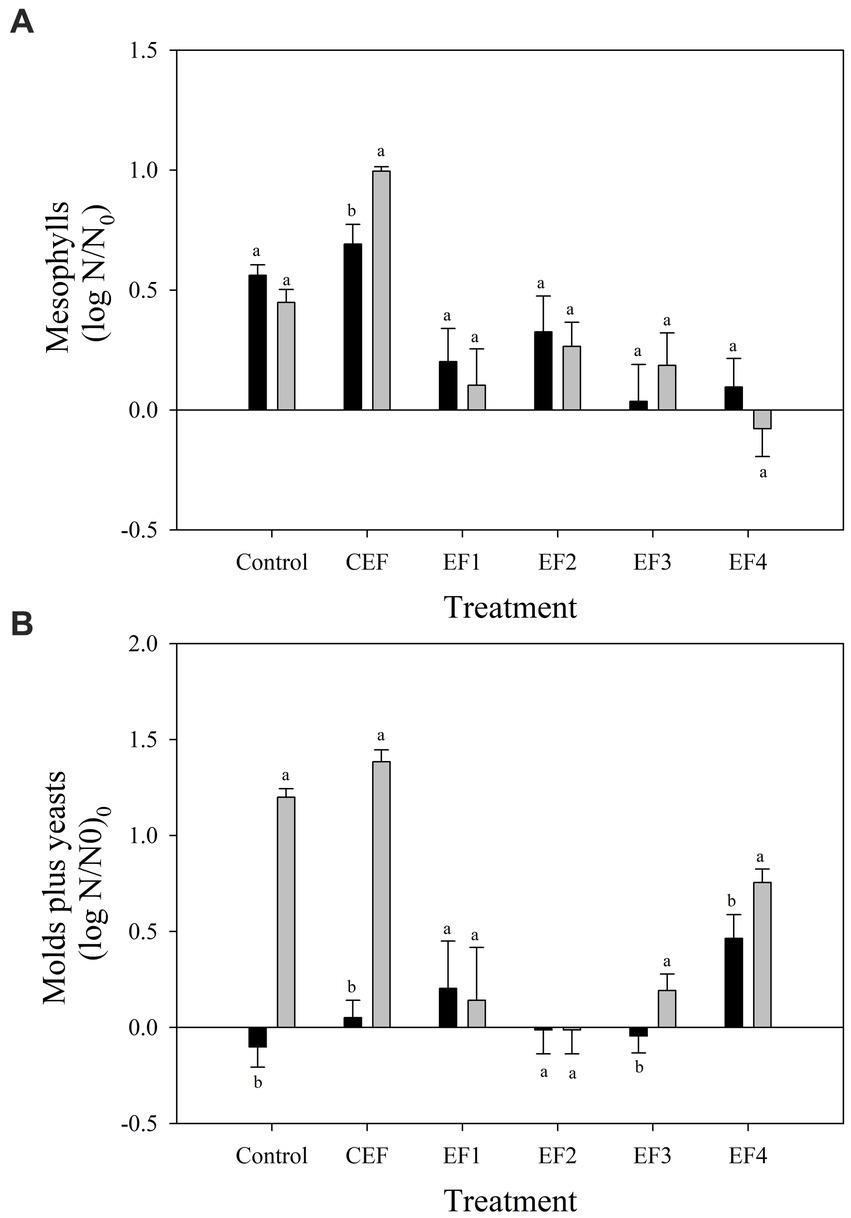

The total phenolic compounds and antioxidant capacity of guacamole after 48 h of storage at 4 and 20°C are presented in Figure 2. At the beginning of the storage, phenolic compounds and antioxidant capacity presented values of 23.29 to 33.51 mg GAE/100 g and 29.73 to 57.37 mg Trolox/100 g, with a slight increment in the antioxidant capacity due to the addition of the EF with lemon-onion extract (EF1-EF4), which may be attributed to the total phenolic compounds (1180.44–1856.00 mg GAE/100 g) and antioxidant capacity of the EF (878.07–1201.22 mg Trolox/100 g), related to the antioxidant compounds of lemon and onion extracts (Rodríguez-Campos et al., 2022). Moreover, values of total phenolic compounds and antioxidant capacity were slightly higher than those reported by Rodríguez-Carpena et al. (2011), who informed values of 17.19–22.62 mg GAE/100 g for total phenolic compounds and 8–0-9.25 mg Trolox/100 g of antioxidant capacity of “avocado pulp cv. Hass.” Variation in these compounds is generally associated with the agronomic factors during pre- and post-harvest management and the extraction and quantification of bioactive compounds (Jattar-Santiago et al., 2022). After 48 h of storage, a reduction of phenolic compounds was observed. However, no effect of storage conditions and the EF was observed. Contrarily, the antioxidant capacity was affected by both EF and storage conditions; interestingly, guacamole with EF1 showed higher antioxidant capacity at both temperatures (p < 0.05 at 20°C). Therefore, it is possible to infer that the lesser effect of color change in guacamole added with EF1 was due to its antioxidant capacity, which also possesses a higher quantification among formulated EFs (1201.22 ± 76.64 mg Trolox/100 g). In this sense, under oxidative stress conditions, the antioxidant capacity of avocado pulp is mainly related to its tocopherol content (γ- tocopherol mainly), which donated hydrogen to alyl or alkyl peroxy radicals of avocado pulp. These tocopherols are stabilized through hydrogen donation by the ascorbic acid or flavonoids contained in the lemon-onion extract (Basavegowda and Baek, 2021; Yin et al., 2021; Chirinos et al., 2022). On the other hand, although citric acid is an antioxidant compound when it is added to the chitosan film formulation, it can act as a cross-linker giving stability to the EFs. In this sense, it is possible that increasing the amount of citric acid in the EF formulation reduces the action of lemon-onion extract, thus showing a reduction in the antioxidant capacity of EF (Priyadarshi et al., 2018).

Figure 2. Total phenolic compounds (A) and antioxidant capacity (B) of guacamole with and without EF (control). Black columns: 0 days of storage; gray columns: 48 h of storage at 4°C; and dark gray columns: 48 h of storage at 20°C. Bars indicate standard deviation. Different letters in treatments indicate statistical differences (p < 0.05).

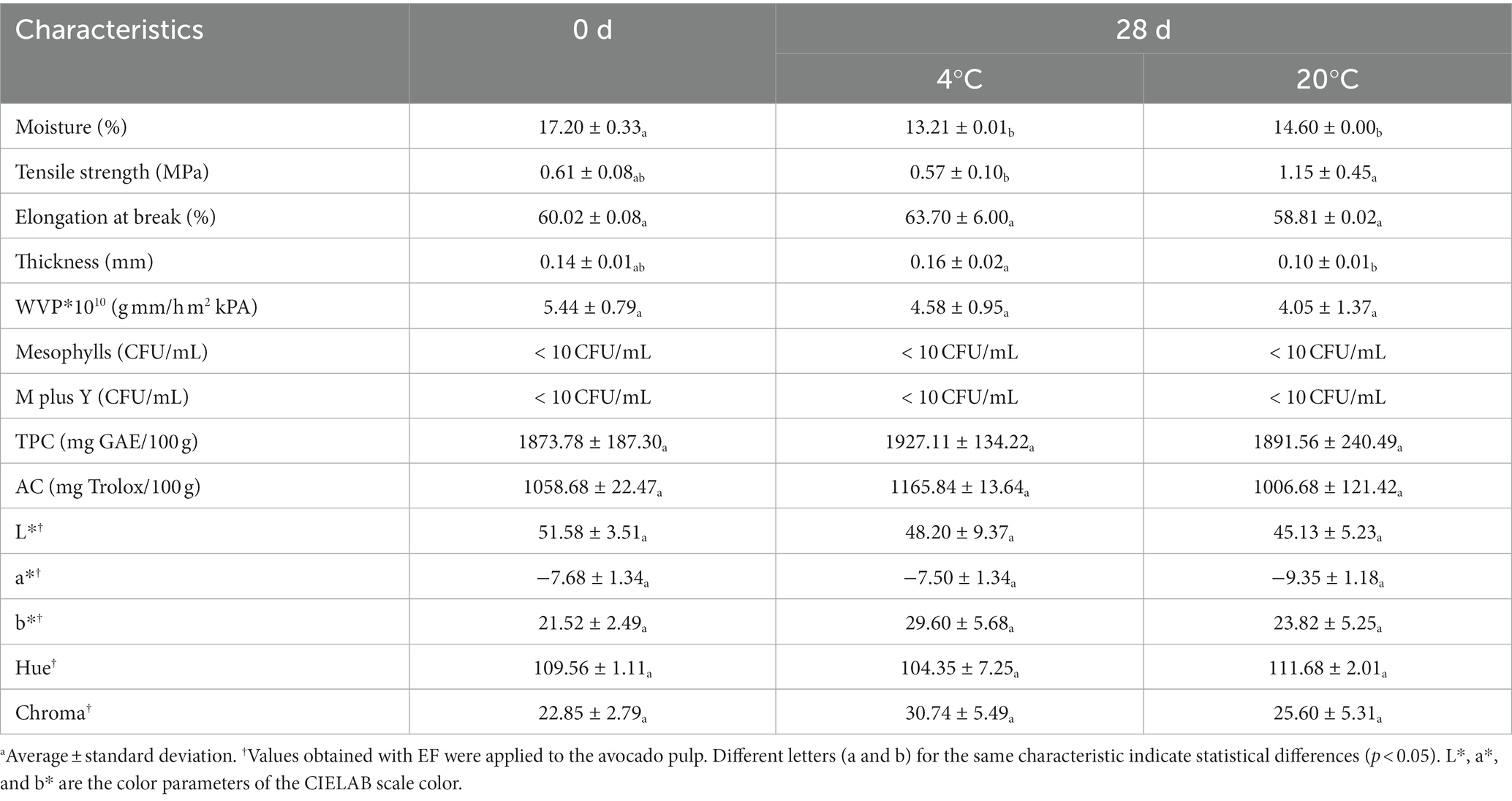

One of the main characteristics of EFs is protecting against contamination and microbial spoilage. In this sense, chitosan has been proven to reduce the microbial growth of several food products (Abdel-Naeem et al., 2021; Xu et al., 2021). Figure 3 shows the mesophylls and molds plus yeast growth in guacamole with and without EF. It is important to point out that microbial load depends on good manufacturing practices, which in this case was adequate because, at the beginning of the storage, less than 100 CFU/g of mesophylls and 10 CFU/g of molds plus yeasts were counted. After 48 h of storage, the maximum mesophyll growth was approximately 1 log cycle (0.99 ± 0.02 log) in CEF at 20°C, whereas molds plus yeasts were significantly higher in control and CEF (less than 100 CFU/g). However, guacamole stored with EF added with extract maintained its mesophylls and molds plus yeasts counts under 100 CFU/g and 10 CFU/g, respectively. As was observed, in all cases, the microbial load was controlled during the storage of guacamole and was far from the limits established by the Health Protection Agency (2009), of 106–108 CFU/g in ready-to-eat products. Moreover, results indicate the effect of the lemon-onion extract in maintaining or even reducing microbial load. In this sense, thiosulfinates in onions may be responsible for the antimicrobial activity of EFs (Loredana et al., 2019). According to the results obtained in the first part of this study, edible film 1 (EF1) was selected for an evaluation of its physical, microbiological, and antioxidant characteristics after 28 days of storage (at 4 and 20°C) and to assay its capacity for maintaining quality characteristics of guacamole.

Figure 3. Mesophylls (A) and molds plus yeasts (B) of guacamole with and without EF (control). Black columns: 48 h of storage at 4°C and gray columns: 48 h of storage at 20°C. Bars indicate standard deviation. Different letters in treatments indicate statistical differences (p < 0.05).

3.2. Characterization and evaluation of the stability of selected edible film

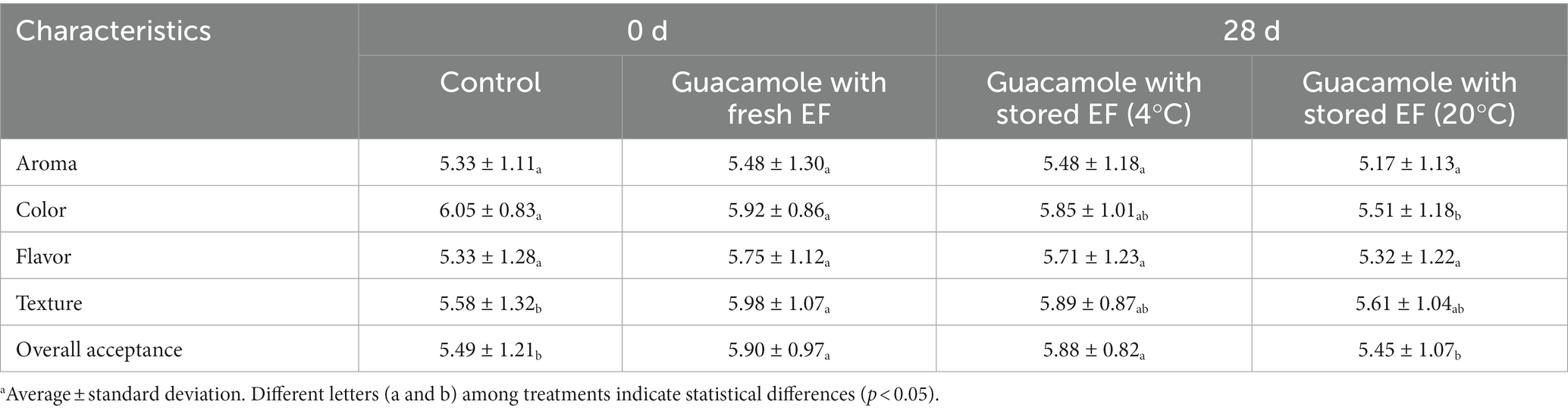

The physical, microbiological, and antioxidant characteristics of EF1 at the beginning and after 28 days of storage at 4 and 20°C are provided in Table 3. The moisture content, tensile strength, extension, and WVP are in the range of those reported (10.8–31.3%, 3.85–9.2 × 1010 g/smPa, 0.15–1.22 MPa, 81.24–97.45%, respectively) by other EFs based on chitosan at a similar concentration (Cerqueira et al., 2012; Homez-Jara et al., 2018). The moisture content and WVP reduced during the storage of EF (p < 0.05); this reduction may be attributed to the low relative humidity condition (40%) and the consequence of microstructural rearrangement of hydrogen bonds, reducing pores presented in EF. In this sense, Piccirilli et al. (2019) indicated that the moisture content of EF based on whey protein significantly reduced moisture content, changing from 19.1 to 15.4 and 12.5% when films were stored for 28 days at 8 and 25°C, respectively. On the other hand, tensile strength significantly increased at 20°C, while a reduction in thickness was observed at the same temperature. This suggests that increasing the temperature promotes aggregation and/or rearrangement of polymers, decreasing free volume and increasing the tensile strength of EF (Piccirilli et al., 2019). In this sense, an inverse relationship between the thickness and tensile strength of EF based on chitosan was reported (Escamilla-García et al., 2013).

Table 3. Physical, mechanical, microbiological, and antioxidant characteristics of selected EF at the beginning and after 28 days of storage at 4 ± 1 and 20 ± 2°C.a

On the other hand, microbial load and antioxidant properties of EF remained constant during storage, regardless of the temperature, which is of paramount importance because it indicates that EF remained stable during storage and its safety and antioxidant properties did not change, even at the highest storage temperature. In this sense, the antioxidant capacity of EF was corroborated in the color parameter of guacamole when EF1 was applied (Table 4). As observed, no significant effect of storage time and temperature was detected. Therefore, the developed EF fulfills several requirements due to its limited microbial spoilage and oxidative reaction, increasing the shelf life of guacamole (Benbettaïeb et al., 2019).

Table 4. Sensory acceptance of guacamole added with fresh EF and added with EF stored for 28 days at 4 and 20°C.a

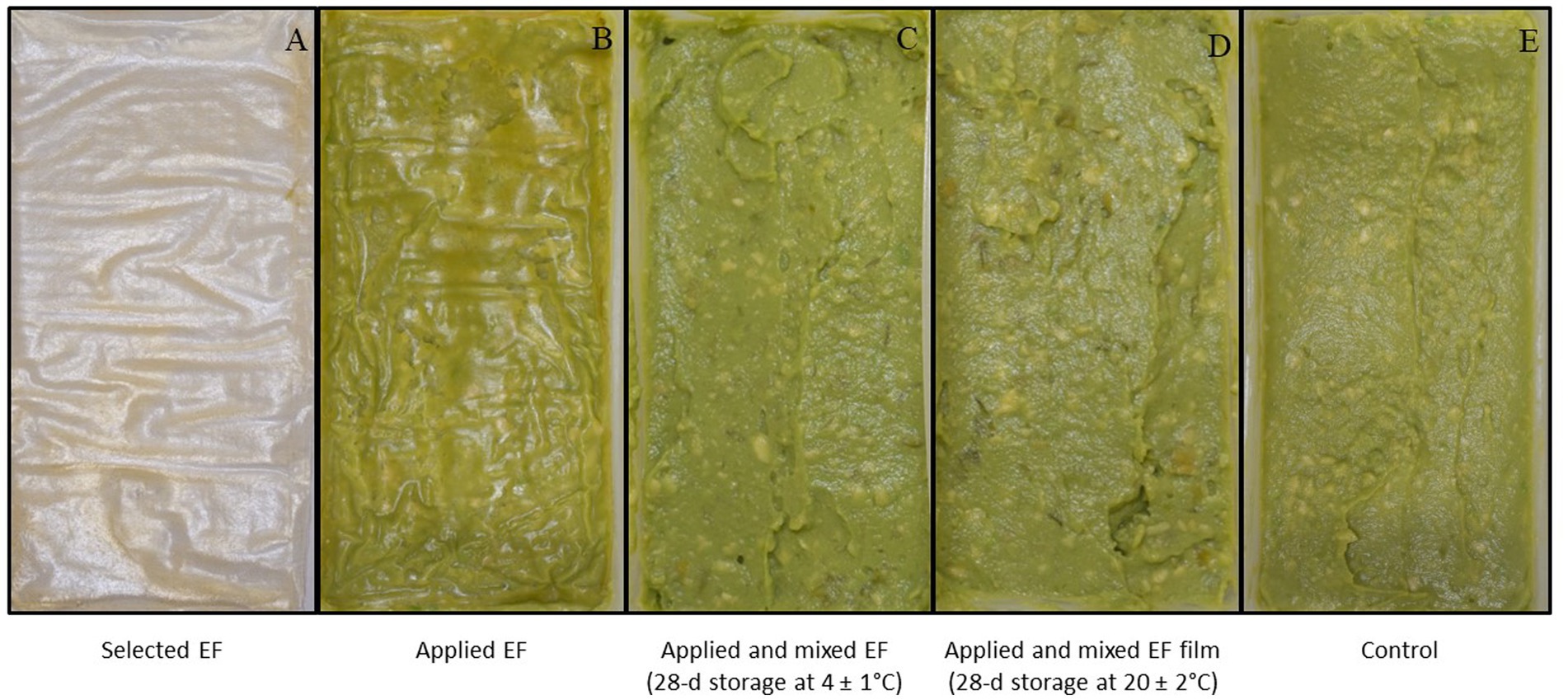

The main characteristic of guacamole rejection by the consumer is likely to be its rapid color change caused by the polyphenol oxidase enzyme and its rancidity flavor caused by the oxidation of lipids. As previously mentioned, a sensory acceptance study was carried out, evaluating the sensory properties and overall acceptance of control guacamole, guacamole with fresh EF, and guacamole with stored EF (Figure 4). It is noteworthy that in all cases when EF was evaluated, it was applied on top of fresh guacamole and left to stand for 24 h at 4°C. After this time, EF and guacamole were mixed and used for sensory evaluation. As was observed, all sensory parameters evaluated were well-accepted by the consumers showing values between 5 and 6, which stood for I like and I like much, respectively. Moreover, consumers did not perceive the addition of fresh and stored EF, regardless of the storage temperature. Overall acceptance of guacamole with fresh and stored (at 4°C) EFs was higher (p < 0.05) than control guacamole and added with stored EF at 20°C. Similar results were obtained by Rodríguez-Campos et al. (2022), who evaluated the sensory acceptance of avocado puree formulated with avocado, lemon, and onion extracts. They informed values of 6 to 8 (I like slightly to I like very much) in a 9-hedonic scale of freshly formulated guacamole. Probably, the adequate acceptance of the taste and flavor of the guacamole with EF obtained in this study was due to lemon-onion extract, two ingredients used for the formulation of guacamole. Moreover, according to Salgado-Cervantes et al. (2019), L* and Hue are the main color parameters for the acceptance of guacamole. They informed values of L* = 56.13–61.11 and Hue = 105.28–110.91, which are very similar to those obtained in this study.

Figure 4. Selected and applied EF on guacamole. (A) Selected EF (EF1); (B) Applied EF and stored for 24 h at 4°C; (C) Applied, stored for 24 h at 4°C, and mixed stored EF (28 d of storage at 4 ± 1°C); (D) Applied, stored for 24 h at 4°C, and mixed stored EF (28 d of storage at 20 ± 2°C); and (E) Control guacamole.

4. Conclusion

In this study, EFs based on chitosan, glycerol, citric acid, and lemon-onion extract were formulated and evaluated in their capacity for maintaining the color and microbiological and antioxidant characteristics of guacamole. Results indicated that EFs reduce the color change of guacamole, increase the antioxidant capacity, and reduce the microbial load of mesophylls and molds plus yeasts. Due to the formulated edible film 1 (EF1) showing the best quality characteristics of guacamole, it was selected for evaluation of its physical properties and capacity for maintaining quality characteristics of guacamole after 28 days of storage at 4 and 20°C. EF1 maintains its physical, microbiological, and antioxidant capacity after 28 days of storage, regardless of the temperature. Moreover, EF1 maintains the color characteristics of guacamole, and according to its composition, was well-accepted by the consumer, showing a similar acceptance to fresh guacamole.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

MM-S: Data curation, Writing – original draft. PH-C: Supervision, Visualization, Writing – original draft. CR-L: Methodology, Supervision, Writing – original draft. IR-L: Investigation, Methodology, Project administration, Writing – original draft. CO-V: Conceptualization, Formal analysis, Funding acquisition, Writing – original draft.

Funding

This study was financed by the Vicerrectoría de Investigación y Estudios de Posgrado of the Benemérita Universidad Autónoma de Puebla (Project number: 00234-VIEP2023).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdel-Naeem, H. H., Zayed, N., and Mansour, H. A. (2021). Effect of chitosan and lauric arginate edible coating on bacteriological quality, deterioration criteria, and sensory attributes of frozen stored chicken meat. LWT Food Sci. Technol. 150:111928. doi: 10.1016/j.lwt.2021.111928

Aparicio-Fernández, X., Vega-Ahuatzin, A., Ochoa-Velasco, C. E., Cid-Pérez, S., Hernández-Carranza, P., and Ávila-Sosa, R. (2018). Physical and antioxidant characterization of edible films added with red prickly pear (Opuntia ficus-indica L.) cv. San Martín peel and/or its aqueous extracts. Food Bioprocess Technol. 11, 368–379. doi: 10.1007/s11947-017-2017-x

Araújo, R. G., Rodríguez-Jasso, R. M., Ruiz, H., Pintado, M. M., and Aguilar, C. N. (2018). Avocado by-products: nutritional and functional properties. Trends Food Sci. Technol. 80, 51–60. doi: 10.1016/j.tifs.2018.07.027

ASTM. (1995). Standard test method for tensile properties of thin plastic sheeting, method D 882–95. Philadelphia, PA: American Society for Testing and Materials.

Basavegowda, N., and Baek, K. (2021). Synergistic antioxidant and antibacterial advantages of essential oils for food packaging applications. Biomol. Ther. 11:1267. doi: 10.3390/biom11091267

Benbettaïeb, N., Debeaufort, F., and Karbowiak, T. (2019). Bioactive edible films for food applications: mechanisms of antimicrobial and antioxidant activity. Crit. Rev. Food Sci. Nutr. 59, 3431–3455. doi: 10.1080/10408398.2018.1494132

Bhargava, N., Sharanagat, V. S., Mor, R. S., and Kumar, K. (2020). Active and intelligent biodegradable packaging films using food and food waste-derived bioactive compounds: A review. Trends Food Sci. Technol. 105, 385–401. doi: 10.1016/j.tifs.2020.09.015

Bizymis, A. P., and Tzia, C. (2022). Edible films and coatings: properties for the selection of the components, evolution through composites and nanomaterials, and safety issues. Crit. Rev. Food Sci. Nutr. 62, 8777–8792. doi: 10.1080/10408398.2021.1934652

Bustos, M. C., Mazzobre, M. F., and Buera, M. P. (2015). Stabilization of refrigerated avocado pulp: effect of Allium and Brassica extracts on enzymatic browning. LWT Food Sci. Technol. 61, 89–97. doi: 10.1016/j.lwt.2014.11.026

Cerqueira, M. A., Souza, B. W. S., Teixeira, J. A., and Vicente, A. A. (2012). Effects of interactions between the constituents of chitosan-edible films on their physical properties. Food Bioprocess Technol. 5, 3181–3192. doi: 10.1007/s11947-011-0663-y

Chaudhary, B. U., Lingayat, S., Banarjee, A. N., and Kale, R. D. (2022). Preparation and characterization of antioxidant, antimicrobial, and UV-light protection film based on poly (vinyl alcohol) and garlic peel extract. Waste Biomass Valorization 13, 4717–4734. doi: 10.1007/s12649-022-01804-y

Chirinos, R., Ramon, K., Mendoza, M., Figueroa-Merma, A., Pacheco-Ávalos, A., Campos, D., et al. (2022). Effect of prolonged cold storage on the dynamics of the enzymatic and non-enzymatic antioxidant system in the mesocarp of avocado (Persea americana) cv. Hass: relationship with oxidative processes. Horticulturae 8:880. doi: 10.3390/horticulturae8100880

Cid-Pérez, T. S., Hernández-Carranza, P., Ochoa-Velasco, C. E., Ruiz-López, I. I., Nevárez-Moorillón, G. V., and Ávila-Sosa, R. (2021). Avocado seeds (Persea americana cv. Criollo sp.): lipophilic compounds profile and biological activities. Saudi J. Biol. Sci. 28, 3384–3390. doi: 10.1016/j.sjbs.2021.02.087

Cortés-Rodríguez, M., Orrego-Vargas, F. S., and Rodríguez-Sandoval, E. (2019). Optimization of guacamole formulation made with avocado powder and fresh avocado. Rev. DYNA 86, 126–134. doi: 10.15446/dyna.v86n209.72930

Dalile, B., Kim, C., Challinor, A., Geurts, L., Gibney, E. R., Galdos, M. V., et al. (2022). The EAT–lancet reference diet and cognitive function across the life course. Lancet Planet 6, e749–e759. doi: 10.1016/S2542-5196(22)00123-1

Díaz-Montes, E., and Castro-Muñoz, R. (2021). Edible films and coatings as food-quality preservers: an overview. Foods 10:249. doi: 10.3390/foods10020249

Escamilla-García, M., Calderón-Domínguez, G., Chanona-Pérez, J. J., Farrera-Rebollo, R. R., Andraca-Adame, J. A., Arzate-Vázquez, I., et al. (2013). Physical and structural characterisation of zein and chitosan edible films using nanotechnology tools. Int. J. Biol. Macromol. 61, 196–203. doi: 10.1016/j.ijbiomac.2013.06.051

Fuentes Campo, A., Sancho, M., Melo, G., Dávila, Y. A., and Gasull, E. (2019). In vitro and in vivo inhibition of Hass avocado polyphenol oxidase enzymatic browning by paeonol, β-cyclodextrin, and paeonol: β-cyclodextrin inclusion complex. J. Biosci. Bioeng. 127, 703–709. doi: 10.1016/j.jbiosc.2018.11.009

Galus, S., Kibar, E. A. A., Gniewosz, M., and Krasniewska, K. (2020). Novel materials in the preparation of edible films and coatings–a review. Coatings 10:674. doi: 10.3390/coatings10070674

Health Protection Agency. (2009). Guidelines for assessing the microbiological safety of ready-to-eat foods. London: Health Protection Agency.

Hernández-Carranza, P., Ávila-Sosa, R., Guerrero-Beltrán, J. A., Navarro-Cruz, A. R., Corona-Jiménez, E., and Ochoa-Velasco, C. E. (2016). Optimization of antioxidant compounds extraction from fruit by-products: apple pomace, orange and banana peel. J. Food Process. Preserv. 40, 103–115. doi: 10.1111/jfpp.12588

Hernández-Carranza, P., Heredia-Soberanes, K., Ruiz-López, I. I., and Ochoa-Velasco, C. E. (2022). Effect of impregnation-osmodehydration with Hibiscus sabdariffa extracts on the bioactive compounds and sensory acceptance of apple wedges: fresh, convective dried, and stored. J. Food Process. Preserv. 46:e17110. doi: 10.1111/jfpp.17110

Hirvonen, K., Bai, Y., Headey, D., and Masters, W. A. (2020). Affordability of the EAT–lancet reference diet: a global analysis. Lancet Glob. Health 8, e59–e66. doi: 10.1016/S2214-109X(19)30447-4

Homez-Jara, A., Daza, L. D., Aguirre, D. M., Muñoz, J. A., Solanilla, J. F., and Váquiro, H. A. (2018). Characterization of chitosan edible films obtained with various polymer concentrations and drying temperatures. Int. J. Biol. Macromol. 113, 1233–1240. doi: 10.1016/j.ijbiomac.2018.03.057

Iversen, L. J. L., Rovina, K., Vonnie, J. M., Matanjun, P., Erna, K. H., Aqilah, N. M. N., et al. (2022). The emergence of edible and food-application coatings for food packaging: A review. Molecules 27:5604. doi: 10.3390/molecules27175604

Jattar-Santiago, K. Y., Ramírez-López, C., Hernández-Carranza, P., Avila-Sosa, R., Ruiz-López, I. I., and Ochoa-Velasco, C. E. (2022). Effect of extraction conditions on the antioxidant compounds from habanero pepper (Capsicum chinense) and its potential use as antimicrobial. J. Food Process. Preserv. 46:e16427. doi: 10.1111/jfpp.16427

Kimaru, K. S., Muchemi, K. P., and Mwangi, W. (2020). Effects of anthracnose disease on avocado production in Kenya. Cogent Food Agric. 6:1799531. doi: 10.1080/23311932.2020.1799531

Kumar, L., Ramakanth, D., Akhila, K., and Gaikwad, K. K. (2022). Edible films and coatings for food packaging applications: a review. Environ. Chem. Lett. 20, 875–900. doi: 10.1007/s10311-021-01339-z

Loredana, L., Giuseppina, A., Filomena, N., Florinda, F., Marisa, D., and Donatella, A. (2019). Biochemical, antioxidant properties and antimicrobial activity of different onion varieties in the Mediterranean area. J. Food Meas Charact 13, 1232–1241. doi: 10.1007/s11694-019-00038-2

Magri, A., Cice, D., Capriolo, G., and Petriccione, M. (2022). Effects of ascorbic acid and melatonin treatments on antioxidant system in fresh-cut avocado fruits during cold storage. Food Bioprocess Technol. 15, 2468–2482. doi: 10.1007/s11947-022-02892-3

Martínez-Padilla, L. P., Franke, L., and Juliano, P. (2017). Characterisation of the viscoelastic properties of avocado puree for process design applications. Biosyst. Eng. 161, 62–69. doi: 10.1016/j.biosystemseng.2017.06.016

Morone, P., Falcone, P. M., and Lopolito, A. (2019). How to promote a new and sustainable food consumption model: A fuzzy cognitive map study. J. Clea Prod. 208, 563–574. doi: 10.1016/j.jclepro.2018.10.075

Muñoz-Redondo, J. M., Bertoldi, D., Tonon, A., Ziller, L., Camin, F., and Moreno-Rojas, J. M. (2022). Multi-element and stable isotopes characterization of commercial avocado fruit (Persea americana Mill) with origin authentication purposes. Food Control 137:108975. doi: 10.1016/j.foodcont.2022.108975

Ospina, S., Ortiz, D. L., and Orrego, C. E. (2018). Enzymatic browning and color evolution in frozen storage of two kinds of minimally processed avocado puree. Int. J. Food Eng. 15, 11–12. doi: 10.1515/ijfe-2018-0431

Piccirilli, G. N., Sozao, M., Pérez, L. M., Delorenzi, N. J., and Verdini, R. A. (2019). Effect of storage conditions on the physicochemical characteristics of edible films based on whey protein concentrate and liquid smoke. Food Hydrocoll. 87, 221–228. doi: 10.1016/j.foodhyd.2018.08.015

Priyadarshi, R., Sauraj, S., Kumar, B., and Negi, Y. S. (2018). Chitosan film incorporated with citric acid and glycerol as an active packaging material for extension of green chilli shelf life. Carbohydr. Polym. 195, 329–338. doi: 10.1016/j.carbpol.2018.04.089

Ribeiro, A. M., Estevinho, B. N., and Rocha, F. (2021). Preparation and incorporation of functional ingredients in edible films and coatings. Food Bioprocess Technol. 14, 209–231. doi: 10.1007/s11947-020-02528-4

Rodríguez-Campos, S. V., Hernández-Carranza, P., Ávila-Sosa, R., Ruiz-López, I. I., and Ochoa-Velasco, C. E. (2022). Effect of natural extracts addition on antioxidant, color and sensory properties of avocado (Persea americana cv. Criollo sp.) puree. J Food Meas Charact 14, 2623–2634. doi: 10.1007/s11694-020-00509-x

Rodríguez-Carpena, J. G., Morcuende, D., Andrade, M. J., Kylli, P., and Estévez, M. (2011). Avocado (Persea americana Mill.) phenolics, in vitro antioxidant and antimicrobial activities, and inhibition of lipid and protein oxidation in porcine patties. J. Agric. Food Chem. 59, 5625–5635. doi: 10.1021/jf1048832

Sáez-Orviz, S., Marcet, I., Rendueles, M., and Díaz, M. (2021). Bioactive packaging based on delipidated egg yolk protein edible films with lactobionic acid and Lactobacillus plantarum CECT 9567: characterization and use as coating in a food model. Food Hydrocoll. 119:106849. doi: 10.1016/j.foodhyd.2021.106849

Salgado-Cervantes, M., Servant, A., Maraval, I., Vargas-Ortiz, M., and Pallet, D. (2019). Flash vacuum-expansion process: effect on the sensory, color and texture attributes of avocado (Persea americana) puree. Plant Foods Hum. Nutr. 74, 370–375. doi: 10.1007/s11130-019-00749-3

Salvador-Reyes, R., and Paucar-Menacho, L. M. (2019). Optimization of the blanching time and temperature in the manufacture of Hass avocado pulp using low quality discarded fruits. Braz. J. Food Technol. Campinas 22:e20118244. doi: 10.1590/1981-6723.24418

Siddiqui, S. A., Zannou, O., Bahmid, N. A., Fidan, H., Alamou, A. F., Nagdalian, A. A., et al. (2022). Consumer behavior towards nanopackaging-A new trend in the food industry. Future Foods 6:100191. doi: 10.1016/j.fufo.2022.100191

Statista. (2019). Category share of deli-prepared dips/sauces in grocery stores in the United States in 2019. Available at: https://www.statista.com/statistics/1077392/category-share-of-deli-prepared-dips-sauces-in-grocery-us/ (Accessed December 19, 2022).

Stephen, J., and Radhakrishnan, M. (2022). Avocado (Persea americana Mill.) fruit: nutritional value, handling and processing techniques, and health benefits. J. Food Process. Preserv. 46:e17207. doi: 10.1111/jfpp.17207

Xu, D., Chen, T., and Liu, Y. (2021). The physical properties, antioxidant and antimicrobial activity of chitosan–gelatin edible films incorporated with the extract from hop plant. Polym. Bull. 78, 3607–3624. doi: 10.1007/s00289-020-03294-1

Keywords: active edible film, antioxidant compounds, enzymatic browning, lemon-onion extract, avocado

Citation: Mora-Sánchez M, Hernández-Carranza P, Ramírez-López C, Ruiz-López II and Ochoa-Velasco CE (2023) Developing active chitosan-based edible film for extending the shelf life of guacamole. Front. Sustain. Food Syst. 7:1254337. doi: 10.3389/fsufs.2023.1254337

Edited by:

Santosh Kumar, Central Institute of Technology Kokrajhar, IndiaReviewed by:

Mehdi Maqbool, University of Poonch Rawalakot, PakistanSaiful Irwan Zubairi, National University of Malaysia, Malaysia

Copyright © 2023 Mora-Sánchez, Hernández-Carranza, Ramírez-López, Ruiz-López and Ochoa-Velasco. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Carlos Enrique Ochoa-Velasco, carlos.ochoav@correo.buap.mx

Monserrat Mora-Sánchez1

Monserrat Mora-Sánchez1  Paola Hernández-Carranza

Paola Hernández-Carranza Carlos Enrique Ochoa-Velasco

Carlos Enrique Ochoa-Velasco