Contents

History of the Rotary Engine

Borrowing from Ramelli, Scottish inventor James Watt developed the rotary steam engine in 1769. While Ramelli and Watt were the brains behind the rotary engine, Dr. Felix Wankel is known for inventing the first gasoline-powered internal combustion rotary engine in 1957. He imagined “a new type of engine, half turbine, half reciprocating, for automobiles.”

Wankel, who is said to have never learned to drive, signed contracts with NSU—a German bicycle, motorcycle, and auto manufacturer—to use the Wankel engine. NSU used the engine (called the DKM) as a compressor in a housing with a triangular rotor. Wankel built the first true rotary engine (the KKM) with a static housing in 1958. This was the basis of the modern rotary engine.

In 1957, NSU entered the car market with the Prinz, a small, boxy car with twinned air-cooled motorcycle engines. At the 1963 German International Automobile Exhibition in Frankfurt, NSU presented the 1963 Prinz as the first passenger car produced with a Wankel rotary engine. The engine went into series production in 1964 with the NSU Wankel-Spider.

Shop now for rotary enginesHow the Rotary Engine Works

An internal combustion engine has four stages of operation, occurring successively in a cylinder chamber. In the Wankel rotary engine, three of the four operations occur simultaneously.

To understand how a rotary engine works, we’ll first explain how a piston-combustion engine works:

- Typically, there are four-, six-, or eight-cylinder arrangements of pistons. Each piston connects to a crankshaft by a connection rod.

- As the piston moves up and down, it rotates the crankshaft.

- A combustion chamber opposite the crankshaft has valves that let in fuel and air. Additional valves let out the exhaust gasses as the gasoline burns.

- As the piston moves upward, approaching maximum compression, a spark plug ignites the gasoline, causing an explosion that forces the piston downward.

- This rotational motion causes the crankshaft to turn, connecting to the transmission (gearbox) and turning the vehicle’s wheels.

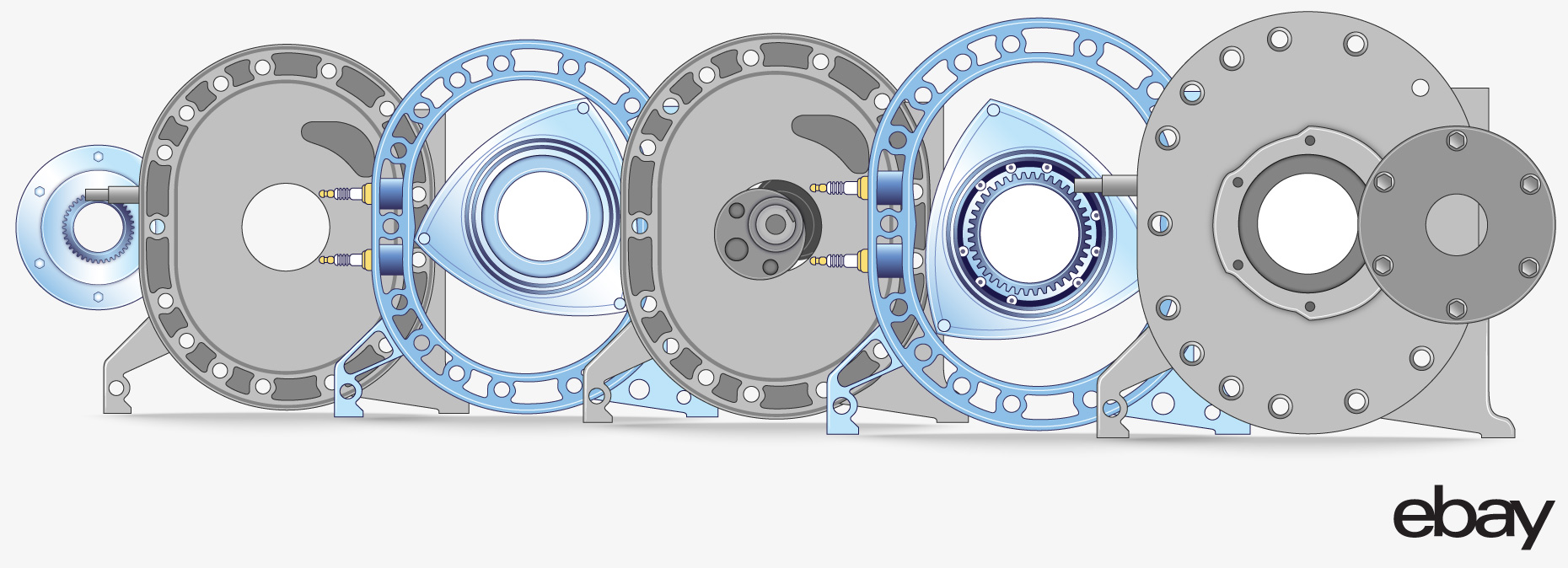

Rotary engines are assembled like sandwiches. This is an exploded view of a two-rotor engine.

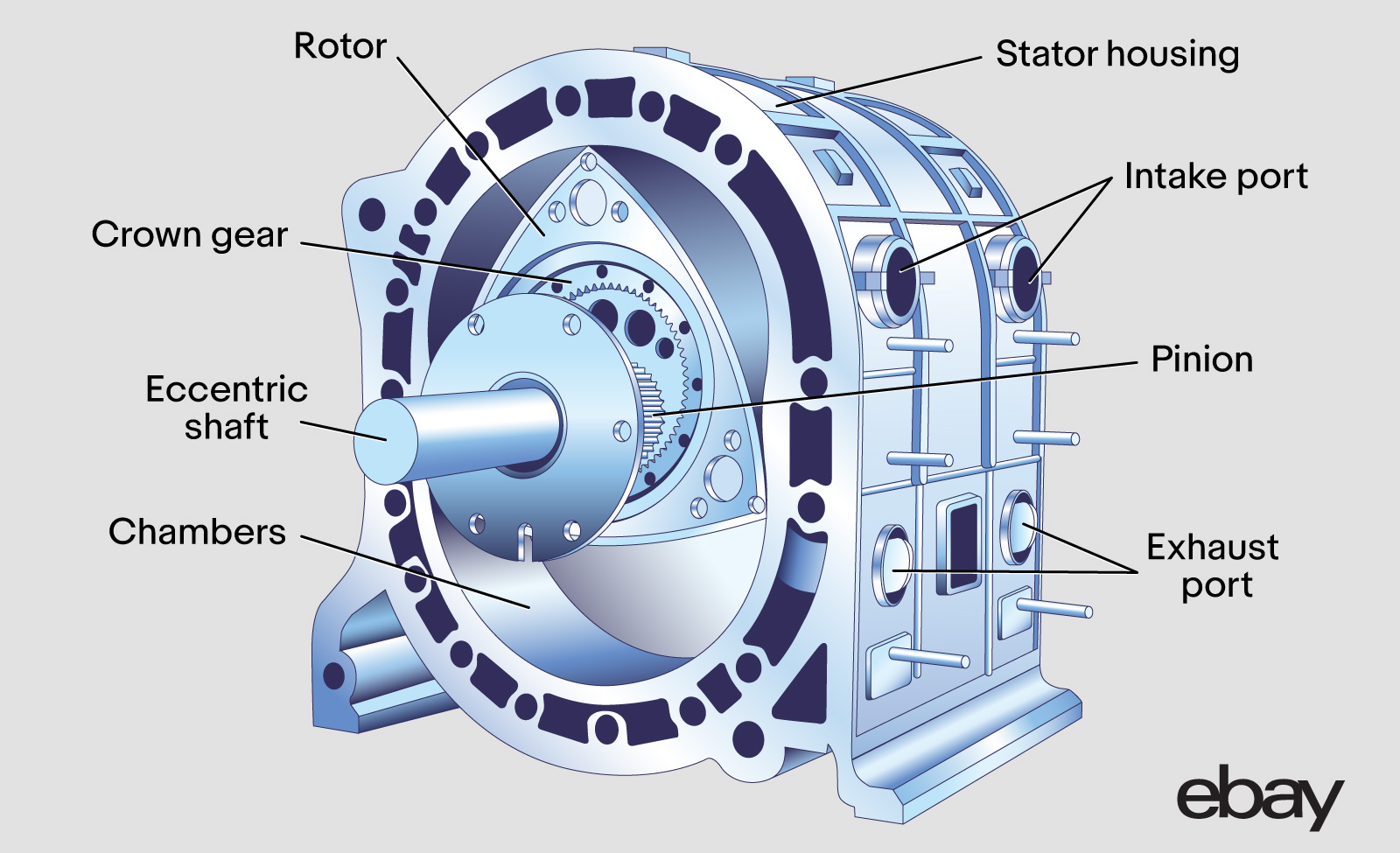

A rotary engine uses about 75 percent fewer moving parts than a similarly powered piston engine. It uses the same motion of compression and combustion but in a completely different way:

- Rather than using pistons and cylinders, it has rotor housings. Within the housings are triangular rotors with curved sides.

- The rotors fit into an oval housing called the epitrochoid (think of it as an oval with pinched-in sides).

- These rotors are geared to an eccentric shaft—the equivalent of a crankshaft in a piston engine—that allows the rotor tips to maintain contact with the housing walls as it spins.

- The triangular shape and housing create voids. They expand and contract depending on where the rotor is during its cycle. This enables each void to handle one aspect of the combustion cycle.

- Rotary engines do not have pistons, timing gears, connecting rods, a crankshaft, or valves, which allows the engine to spin significantly faster—up to 19,000 rpm or more. Typically a piston engine runs 5,000 to 7,000 rpm.

- As the tip of the rotor passes the intake port, the movement sucks the fuel and air mixture into the engine. The next rip of the rotor traps the mixture and sweeps it to the third portion of the housing. The spark plug squeezes it into a tiny area where the mixture explosion occurs, forcing the rotor to continue rotating. This creates the power that drives the engine and transmission.

- In the final step, the spent gasses (exhaust) get swept into an exhaust porthole, pushing it out of the housing.

Pros

- By design, a rotary has much a smaller displacement, allowing for significantly more power than a comparable piston engine.

- The rotary engine is physically smaller and lighter.

- The rotors act like spinning counterweights, which results in smooth and quiet operation and less vibration.

Cons

- Rotary engines are less fuel efficient because they are less thermally efficient.

- Emissions are poor because of the overlap between intake and exhaust events, and it is difficult to meet regulated standards.

- Rotor tips endure significant stress and pressure and experience a high failure rate.

- It has higher oil consumption due to the need to keep rotors and seals lubricated.

Why Was the Rotary Engine Replaced?

By 1967, NSU launched the Ro 80 sedan powered by a two-rotor Wankel engine that produced 113 horsepower. However, developing the Wankel rotary engine was extremely costly for the small German automaker. Leaky apex seals in the rotor and other design flaws severely ruined NSU’s reputation among consumers. Rotor tips would lose contact with the sides of the chamber, damaging the chamber walls. This led to an abundance of warranty claims.

Another issue is that rotary engines aren’t fuel efficient and have difficulty passing regulated exhaust emission tests. Adding to the problems, the engine’s chambers had to be lubricated to prevent damaging the walls. Some of this lubricant would be ejected along with exhaust gasses. In 1969, Volkswagenwerk AG/Audi acquired NSU and phased out the use of Wankel engines.

Mazda Cosmo (Source: Mazda)

Just before Volkswagen’s takeover, NSU sold the license rights for the Wankel engine to other automakers, with permission to develop their own versions. Mazda was an early adopter. In 1967, the Mazda Cosmo Sport became the first mass-production vehicle with a rotary engine.

General Motors paid $50 million for the rights, but their rotary engine production lagged. Poor fuel economy numbers, the 1973 oil crisis, and the massive financial investment needed to retool the Wankel engine severely dampened interest in the rotary engine.

What Is the Future of the Rotary Engine?

Despite their problems, rotary engines are often rumored to be making a comeback. Mazda has maintained a keen interest, saying that Mazda would likely not exist today without it. Conversely, the engine wouldn’t have been in production for nearly 50 years without Mazda. Just eight years ago, Mazda revealed the RX-Vision rotary engine concept at the Tokyo auto show.

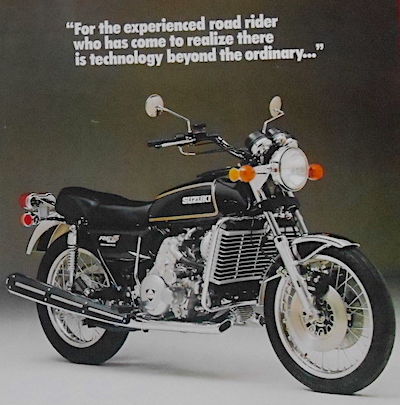

Suzuki billed the rotary-powered RE5 as “the smoothest, most vibration-free motorcycle you’ll ever ride.”

Over the years, rotary-powered vehicles have included:

- The 1974 Mazda Rotary Pickup (REPU)

- Mazda RX-8 sports car (produced until 2002)

- The French-built Citroen GS Birotor sedan

- The Mercedes-Benz C111 concept vehicle that never went into production

Earlier this year, Mazda’s European Communications Department announced that the rotary engine would return, this time on the 2023 MX-30 R-EV, the company’s first electric vehicle. Making its world debut at the Brussels Motor Show in January 2023, the MX-30 e-Skyactiv R-EV is a plug-in hybrid crossover with an electric range of 53 miles and a compact gasoline rotary engine that includes a generator that extends the driving range to more than 372 miles.

The MX-30 EV has only been sold in the US, and Mazda has not indicated if it will sell the rotary-powered hybrid here.

Shop now for rotary engines