Abstract

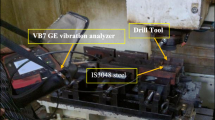

Tool condition is highly relative to the productivity, quality, and safety of ultrasonic vibration-assisted drilling (UVAD) of carbon fiber-reinforced polymer (CFRP). Tool breakage can cause the degradation of drilling quality and maybe even lead to unexpected machine downtime. Therefore, tool breakage monitoring is the key technique of ensuring drilling quality and realizing fully automated drilling. However, existing tool breakage monitoring methods based on machine learning need training model previously, which is impractical for the actual drilling process. In this work, a novel tool breakage monitoring method based on a sequential probability ratio test (SPRT) in UVAD of CFRP is proposed. Three different damage levels are introduced to simulate the tool breakage in the drilling process. The vibration signals collected under different tool damage levels in the experiment are preprocessed by low-pass filtering to remove the disturbance frequency generated by the ultrasonic spindle system. To reduce data redundancy, the signals are downsampled according to the useful frequency band and the feature parameter extracted from test signals is finally fed into the SPRT model as a test sequence to recognize tool damage levels. Root mean square error (RMSE) between the same conditions and between different types of conditions was selected as the criteria to evaluate the reliability of the method. The test results and error analysis show that the method is effective and reliable to classify different tool breakage conditions during UVAD of CFRP.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this article and its additional files.

Code availability

Not applicable.

References

Alessandra C (2018) Machining of fibre reinforced plastic composite materials. Materials 11(3):442

Lee JH, Ge JC, Song JH (2021) Study on burr formation and tool wear in drilling CFRP and its hybrid composites. Appl Sci 11(1):384

Nguyen D, Bin Abdullah MS, Khawarizmi R, Kim D, Kwon P (2020) The effect of fiber orientation on tool wear in edge-trimming of carbon fiber reinforced plastics (CFRP) laminates. Wear 450–451:203213

Wang D, Jiao F, Mao X (2020) Mechanics of thrust force on chisel edge in carbon fiber reinforced polymer (CFRP) drilling based on bending failure theory. Int J Mech Sci 169:105336

Amini S, Baraheni M, Mardiha A (2017) Parametric investigation of rotary ultrasonic drilling of carbon fiber reinforced plastics. Proc Inst Mech Eng E J Process Mech Eng 232(5):540–554

Hou G, Zhang K, Fan X, Luo B, Cheng H, Yan X, Li Y (2020) Analysis of exit-ply temperature characteristics and their effects on occurrence of exit-ply damages during UD CFRP drilling. Compos Struct 231:111456

Fernández-Pérez J, Díaz-Álvarez J, Miguelez M, Cantero J (2021) Combined analysis of wear mechanisms and delamination in CFRP drilling. Compos Struct 255:112774

Siddhpura A, Paurobally R (2013) A review of flank wear prediction methods for tool condition monitoring in a turning process. Int J Adv Manuf Technol 65(1–4):371–393

Patra K, Jha AK, Szalay T, Ranjan J, Monostori L (2017) Artificial neural network based tool condition monitoring in micro mechanical peck drilling using thrust force signals. Precis Eng 48:279–291

Geramifard O, Xu JX, Zhou JH, Li X (2014) Multimodal hidden Markov model-based approach for tool wear monitoring. IEEE Trans Industr Electron 61(6):2900–2911

Klocke F, Döbbeler B, Pullen T, Bergs T (2019) Acoustic emission signal source separation for a flank wear estimation of drilling tools. Procedia CIRP 79:57–62

Simon GD, Deivanathan R (2019) Early detection of drilling tool wear by vibration data acquisition and classification. Manuf Lett 21:60–65

Tsanakas JA, Botsaris PN, Amirids IG, Galeridis GG (2012) Evaluation of sensor-based condition monitoring methods as in-process tool wear and breakage indices-case study: drilling. Diagnostyka 2(62):3–13

Ratava J, Lohtander M, Varis J (2017) Tool condition monitoring in interrupted cutting with acceleration sensors. Robot Comput Integr Manuf 47:70–75

Lu Z, Wang M, Dai W, Sun J (2019) In-process complex machining condition monitoring based on deep forest and process information fusion. Int J Adv Manuf Technol 104(5):1953–1966

Kang G-S, Kim S-G, Yang G-D, Park K-H, Lee DY (2019) Tool chipping detection using peak period of spindle vibration during end-milling of inconel 718. Int J Precis Eng Manuf 20(11):1851–1859

Wald A (1945) Sequential tests of statistical hypotheses. Ann Math Stat 16(2):117–186

Chetouani Y (2014) A sequential probability ratio test (SPRT) to detect changes and process safety monitoring. Process Saf Environ Prot 92(3):206–214

Goodman NA, Venkata PR, Neifeld MA (2007) Adaptive waveform design and sequential hypothesis testing for target recognition with active sensors. IEEE J Sel Topics Signal Proc 1(1):105–113

Chen H, Shang Y, Sun K (2013) Multiple fault condition recognition of gearbox with sequential hypothesis test. Mech Syst Signal Process 40(2):469–482

Li D, Zhang M, Lai Z, Shen Y (2013) Sequential probability ratio test based fault detection method for actuators in gnc system. In: Proceedings of the 32nd Chinese Control Conference. IEEE, pp 6324–6327

Huang W, Cao S, Li HN, Zhou Q, Wu C, Zhu D, Zhuang K (2021) Tool wear in ultrasonic vibration–assisted drilling of CFRP: a comparison with conventional drilling. Int J Adv Manuf Technol 115(5):1809–1820

Nakandhrakumar RS, Dinakaran D, Satishkumar S, Gopal M (2014) Influence of sensor positioning in tool condition monitoring of drilling process through vibration analysis. Adv Mater Res 984–985:564–569

Claudiu F, Bisu M, Zapciu O, Cahuc A, Gérard M (2012) Envelope dynamic analysis: a new approach for milling process monitoring. Int J Adv Manuf Technol 62(5–8):471–486

Tsanakas I, Botsaris P, Galeridis G (2012) Evaluation of sensor-based condition monitoring methods as in-process tool wear and breakage indices – case study: drilling. Diagnostyka: Applied Structural Health Usage and Condition Monitoring 2:3–15

Rafezi H, Akbari J, Behzad M (2012) Tool condition monitoring based on sound and vibration analysis and wavelet packet decomposition. In: 2012 8th International Symposium on Mechatronics and its Applications. IEEE, pp 1–4

Kilundu B, Dehombreux P, Chiementin X (2011) Tool wear monitoring by machine learning techniques and singular spectrum analysis. Mech Syst Signal Process 25(1):400–415

Gao G, Zhong Y, Gao S, Gao B (2021) Double-channel sequential probability ratio test for failure detection in multisensor integrated systems. IEEE Trans Instrum Meas 70:1–14

Syafiq H, Kamarizan M, Ghazali MF, Yusoff AR (2015) Statistical analysis of deep drilling process conditions using vibrations and force signals. MATEC Web of Conferences 74:00002

Funding

The work described in this paper is supported by the State Key Lab of Digital Manufacturing Equipment and Technology (Grant No: DMETKF2020026) and the Key Research and Development Project of Hubei Province (Grant No: 2020BAB033).

Author information

Authors and Affiliations

Contributions

Wenjian Huang: writing-original draft preparation, methodology, data curation; Shiyu Cao: investigation, formal analysis, resources; Qi Zhou: investigation, validation; Chaoqun Wu: reviewing and editing, funding acquisition, conceptualization, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, W., Cao, S., Zhou, Q. et al. Tool breakage monitoring based on sequential hypothesis test in ultrasonic vibration-assisted drilling of CFRP. Int J Adv Manuf Technol 118, 2701–2710 (2022). https://doi.org/10.1007/s00170-021-08050-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08050-x