Purpose

The purpose of the mobile test stand project was to redesign and rebuild the original test stand for Titan, Eclipse’s 800 lb thrust hybrid rocket engine. The original test stand was stationary and used mainly Unistrut, which made it time-consuming to assemble. Due to this design, the entire test stand/engine combination needed to be fully assembled at the test site, which was inconvenient. For the test conducted in March of 2017, engine assembly with the original test stand took over 36 hours to complete.

The new design is mobile, and thus the majority of test stand/engine assembly can take place at our workspace rather than the test site. The mobile test stand also utilizes pneumatic cylinders to raise the engine rather than raising it by hand. All of this combines to make the mobile test stand safer, more effective, and more efficient than the original design.

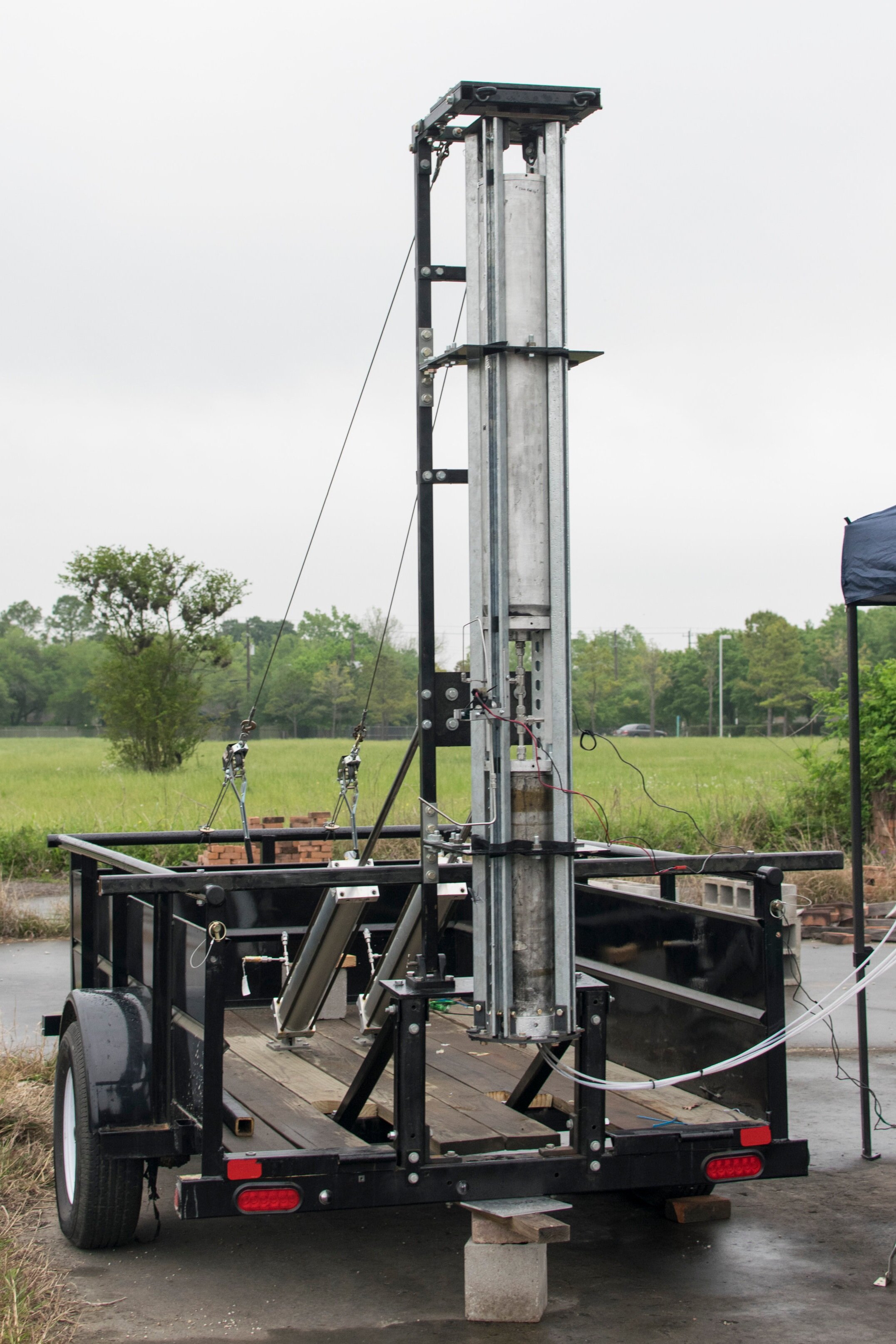

Mobile Test Stand with Titan Engine

Design Components

The mobile test stand is constructed on a trailer base and uses pneumatic cylinders to move the Titan engine between two distinct positions. The engine and test stand can lay horizontally for purposes of assembly and travel and raise into a vertical position for test fires. The engine is secured to the test stand in two ways: a load cell at the top of the engine and three retaining rings surrounding the engine that restrict motion in directions other than desired engine thrust. A flame diverter is secured to the test stand beneath the engine to redirect thrust outward. The mobile test stand is versatile, and can thus be modified and utilized for subsequent hybrid engines built by the team.